Multi-motor driven rice transplanting machine and control method thereof

A multi-motor drive and rice transplanter technology, applied in planting methods, transplanting machinery, applications, etc., can solve the problems of separate control of different transmission mechanisms, low efficiency of medium and small power fuel engines, and increased labor intensity of operators, etc., to achieve Flexible power control capability, reduced production and maintenance costs, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

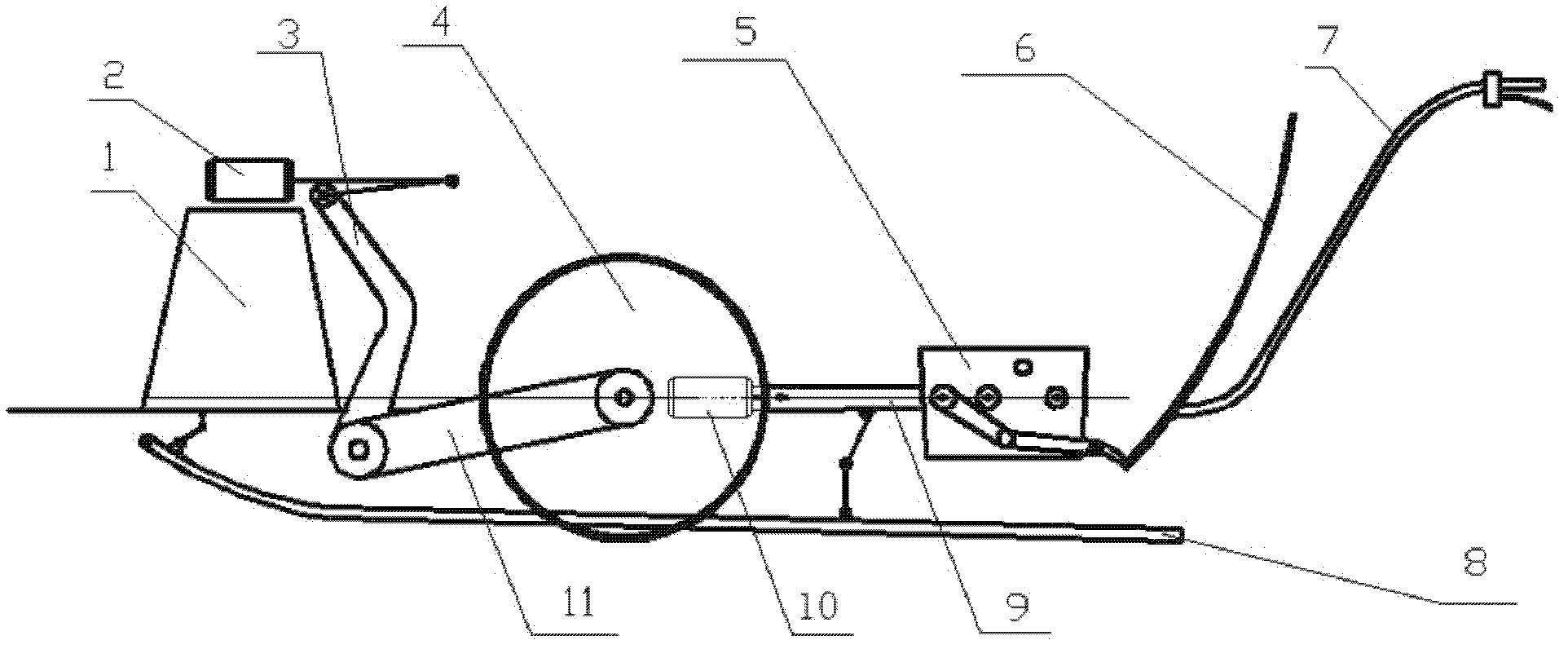

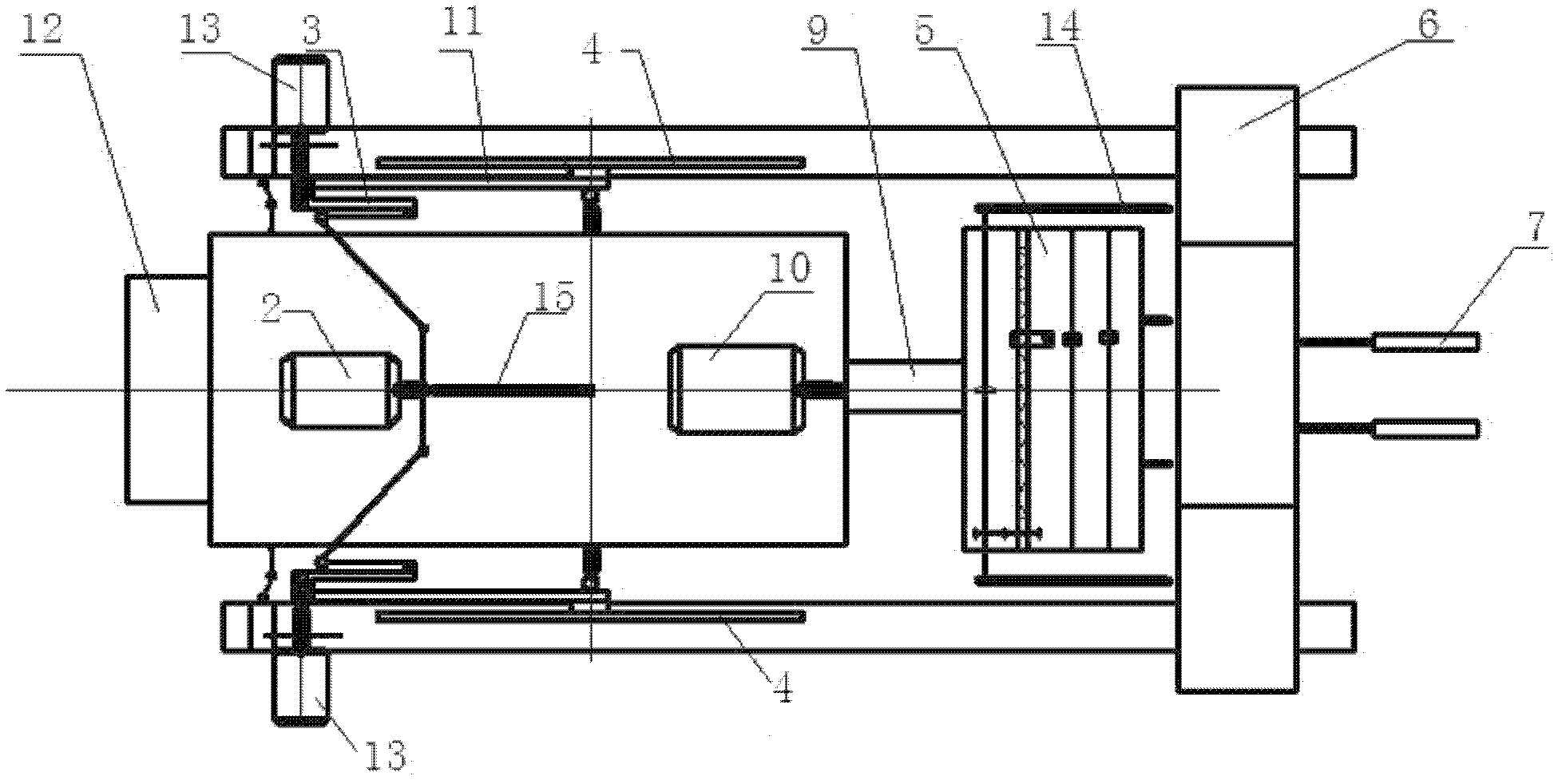

[0029] Such as Figure 1-2As shown, the present embodiment is based on two-wheel 4-row stepping rice transplanter, driven by multiple motors, including rice transplanter frame, two walking water wheel drive motors 13, walking water wheel transmission, walking water wheel 4, A profiling mechanism drive motor 2, a profiling mechanism, a rice transplanting mechanism drive motor 10, a rice transplanting mechanism, a handle 7, a side ship plate 8 and a middle ship plate 12, and the walking water wheel 4 and the side ship plate 8 are all arranged on the rice transplanting The both sides of machine frame walking direction, middle boat plate 12 is arranged in the middle of rice transplanter frame walking direction; Described walking water wheel 4 all links to each other with walking water wheel transmission device, and two walking water wheel drive motors 13 are connected with two respectively. The walking water wheel transmission on the side is connected to each other, and is used to...

Embodiment 2

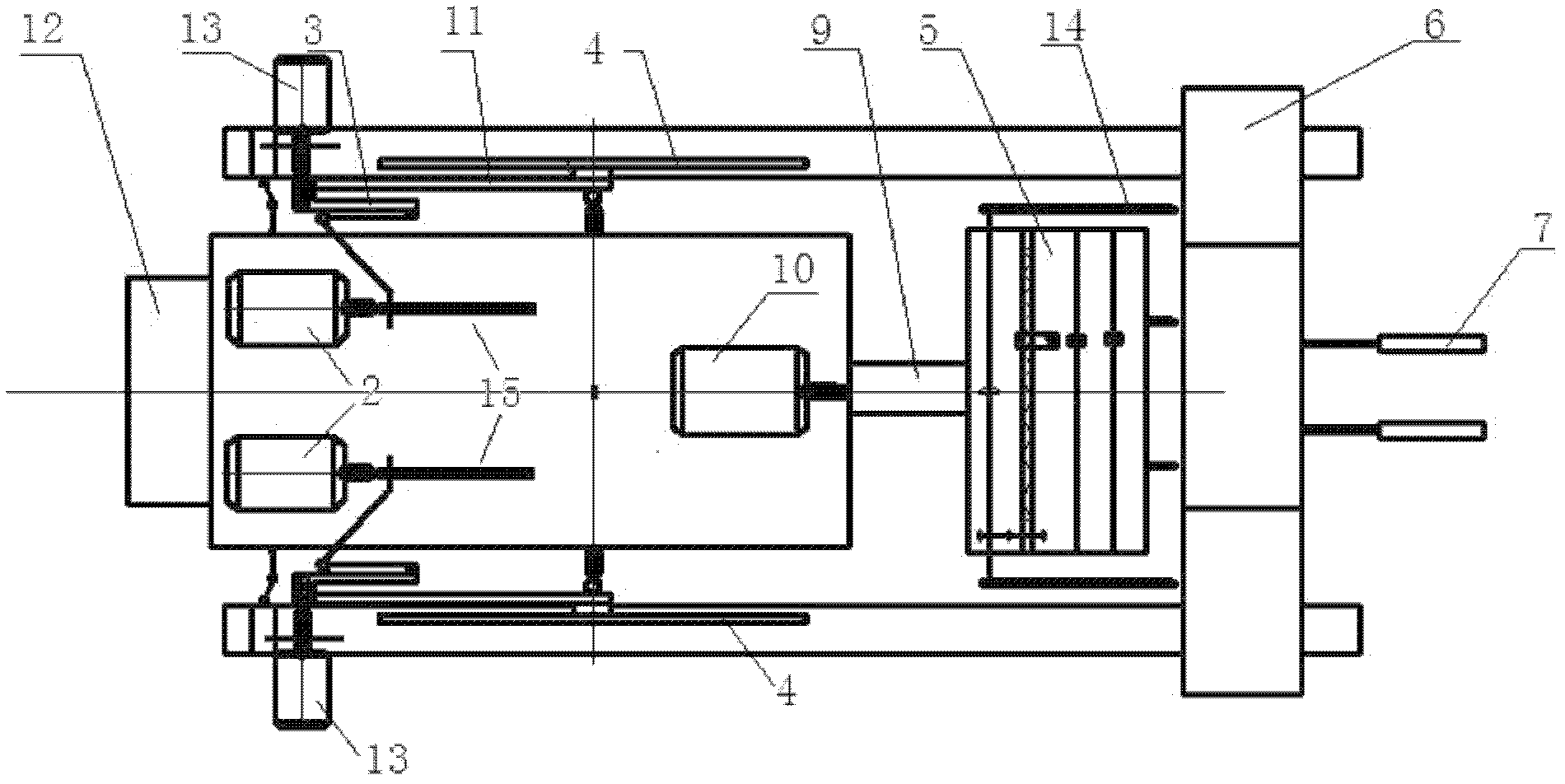

[0044] Present embodiment except following feature other structures are with embodiment 1: as image 3 As shown, there are two profiling mechanism drive motors 2, which drive the profiling mechanisms on the left and right sides respectively. Displacement sensors or pressure sensors are respectively arranged on the side ship plates 8 on both sides, so as to detect the current displacement or pressure of the side ship plates in real time. Adopting two profiling mechanisms to drive the motor can make the two profiling mechanisms work independently, so that the height can be adjusted separately, and the frame of the rice transplanter can be kept parallel to the mud surface when the paddy field is uneven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com