Vertical lathe workstation control system

A control system and vertical lathe technology, applied in the field of control systems, can solve the problems of low precision machining of workpieces, slow running speed, large maintenance amount, etc., and achieve the effects of stable power supply process, stable speed change, and guaranteed machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

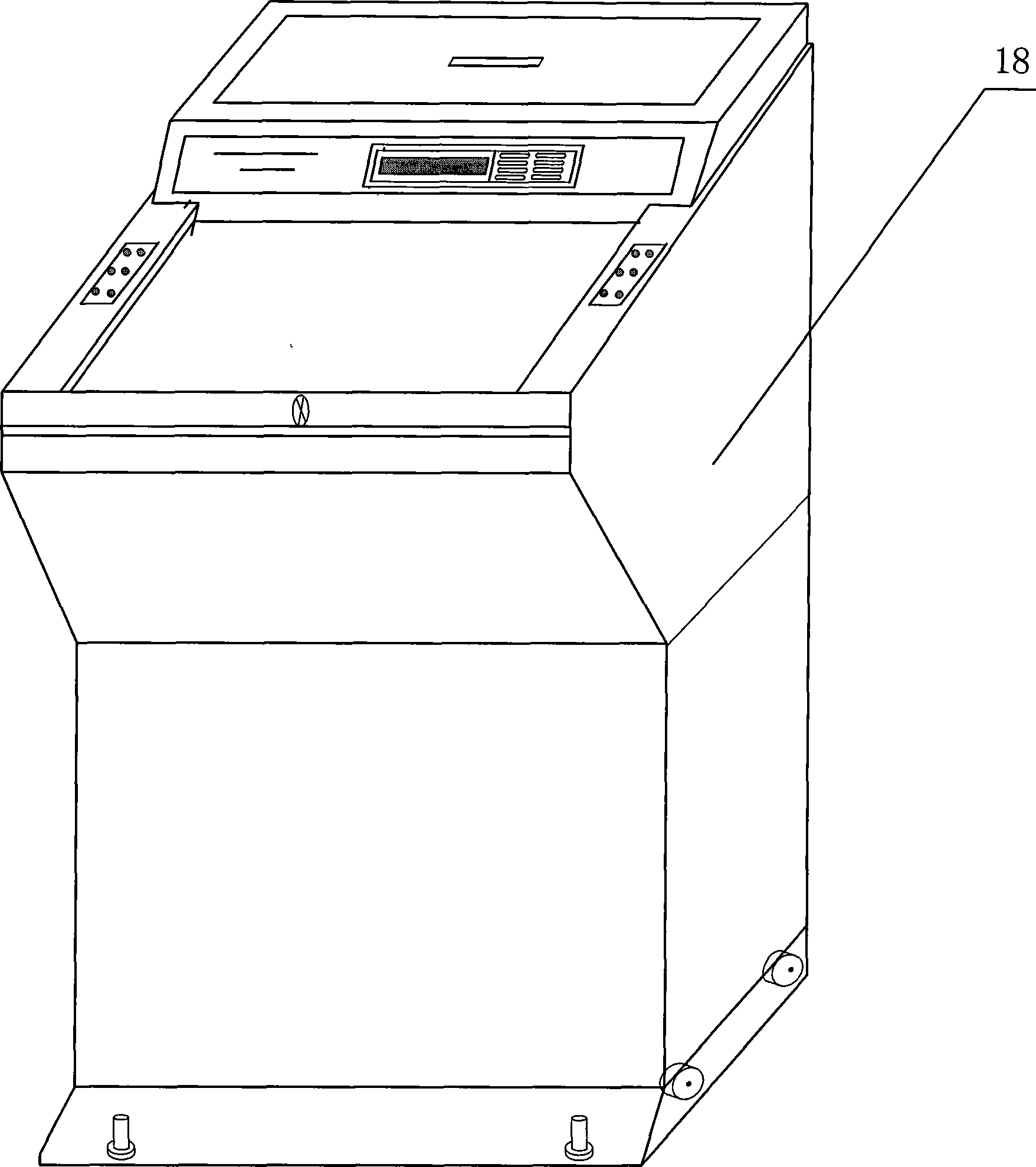

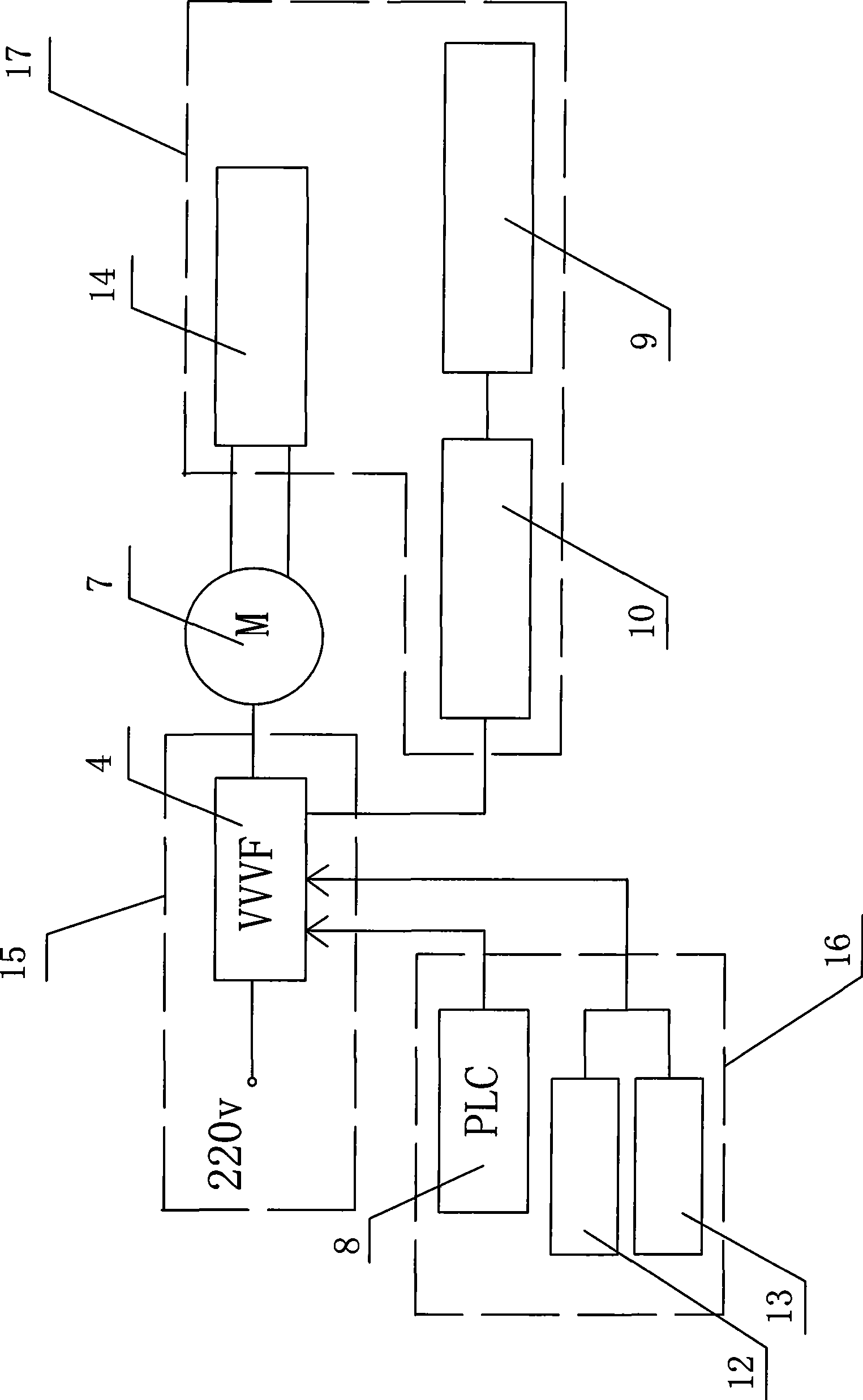

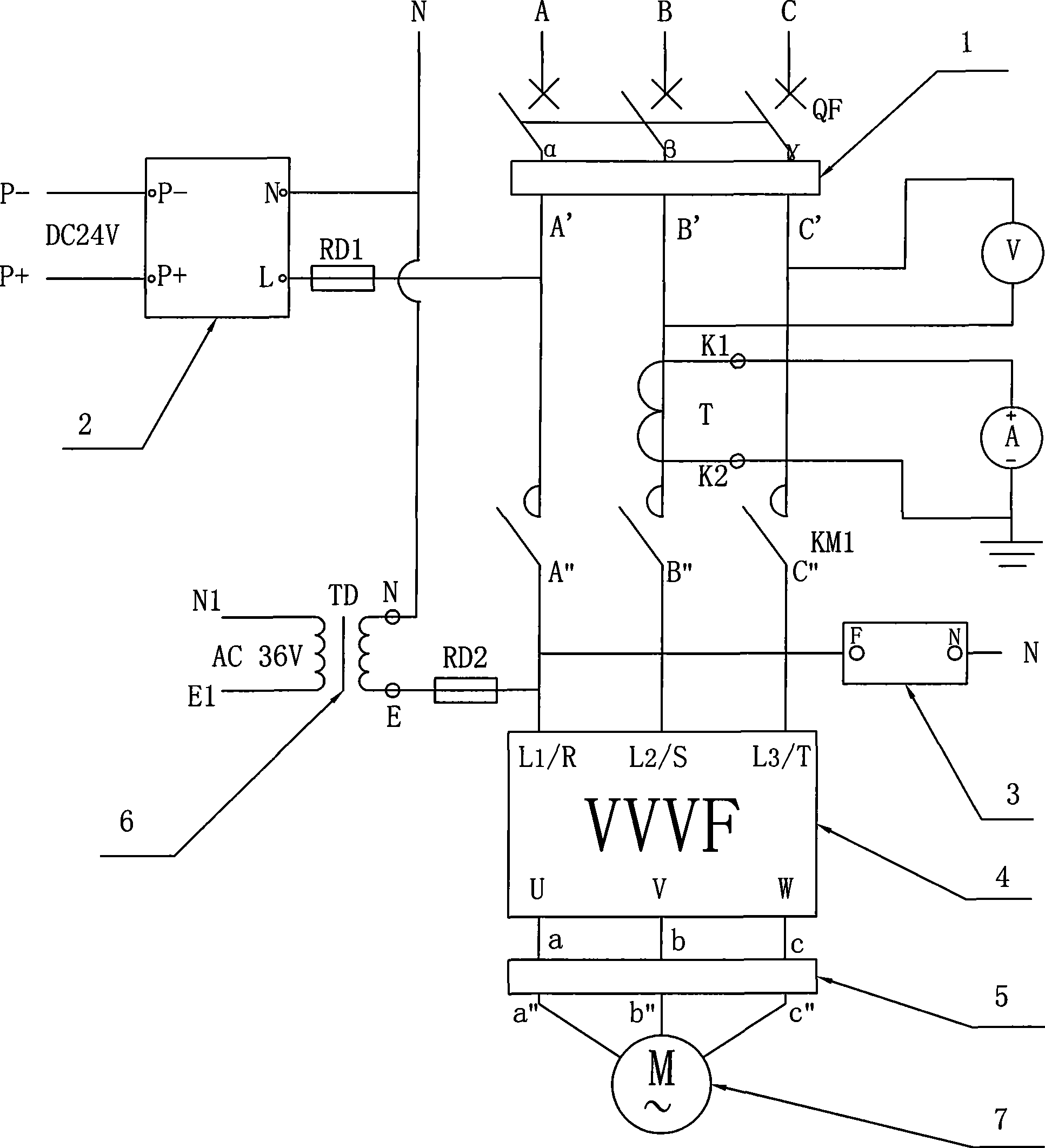

[0049] A vertical lathe table control system, such as figure 1 and 2 As shown, it includes a cabinet body 18 and a main circuit 15 installed in the cabinet body 18, an auxiliary control circuit 16 and a braking unit 17, and the main circuit 15, such as image 3 As shown, it includes combination switch QF, input power filter 1, AC contactor KM1, frequency converter VVVF4 and output power filter 5; the volume of cabinet 18 is 1600mm×2000mm×600mm; the frequency converter VVVF4 is selected with torque vector The general-purpose frequency converter controlled by Japan Fuji is the model FRN55G11S-4CX frequency converter.

[0050] The main circuit 15 is AC A, B, C three-phase four-wire respectively connected to the lead-in end of the combination switch QF, and the lead-out end of the combination switch QF is connected to the input terminal α, β, γ of the input power filter 1 correspondingly, and the input The output terminals A`, B`, C` of the power filter 1 are connected to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com