Multi-point synchronization lifting mechanism composed of steel wire flexible shaft

A technology of steel wire flexible shaft and synchronous lifting, applied in the direction of hoisting devices, etc., can solve the problems of high cost, low synchronization precision, and complexity, and achieve the effect of low cost, high precision, and small mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

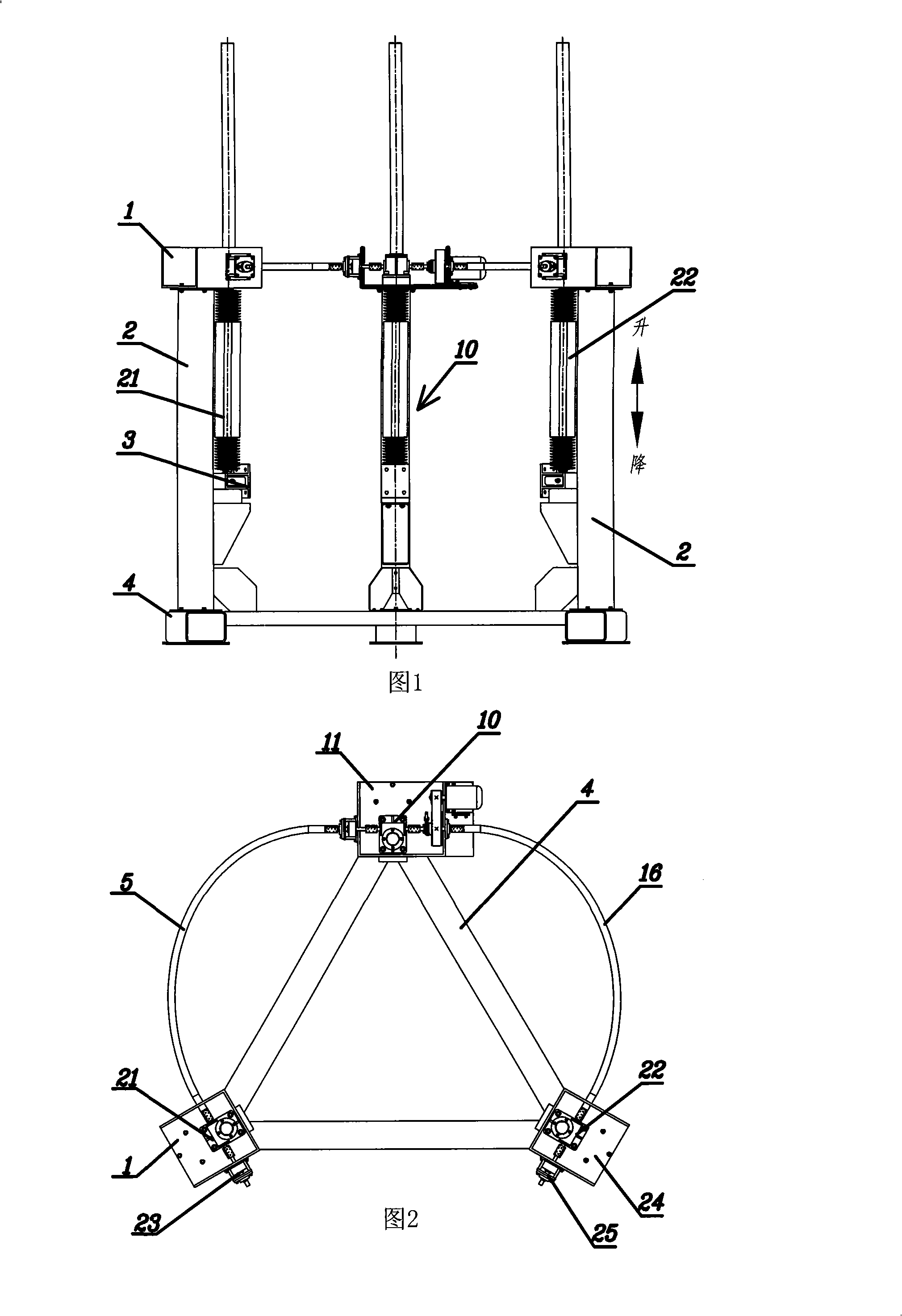

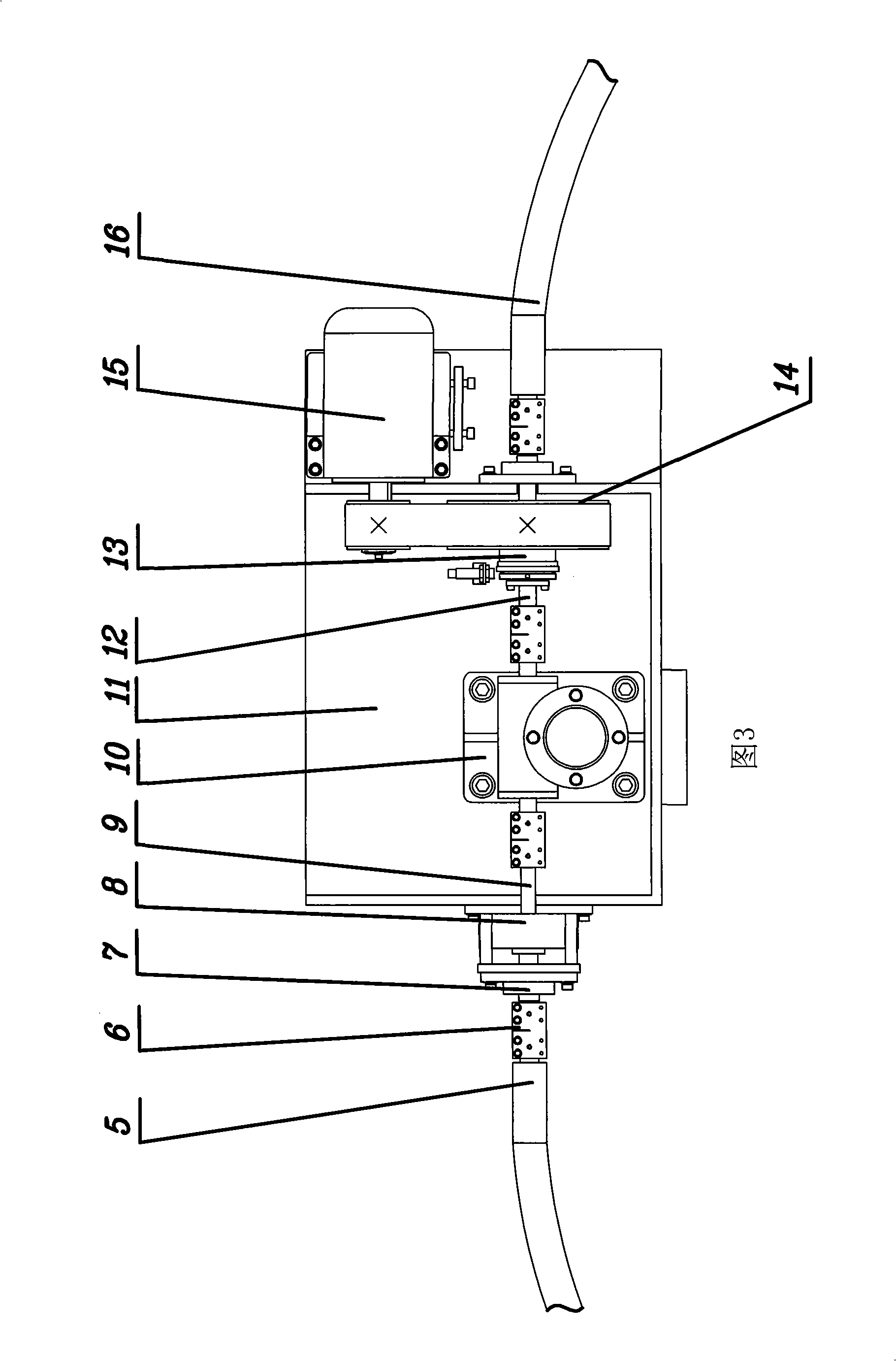

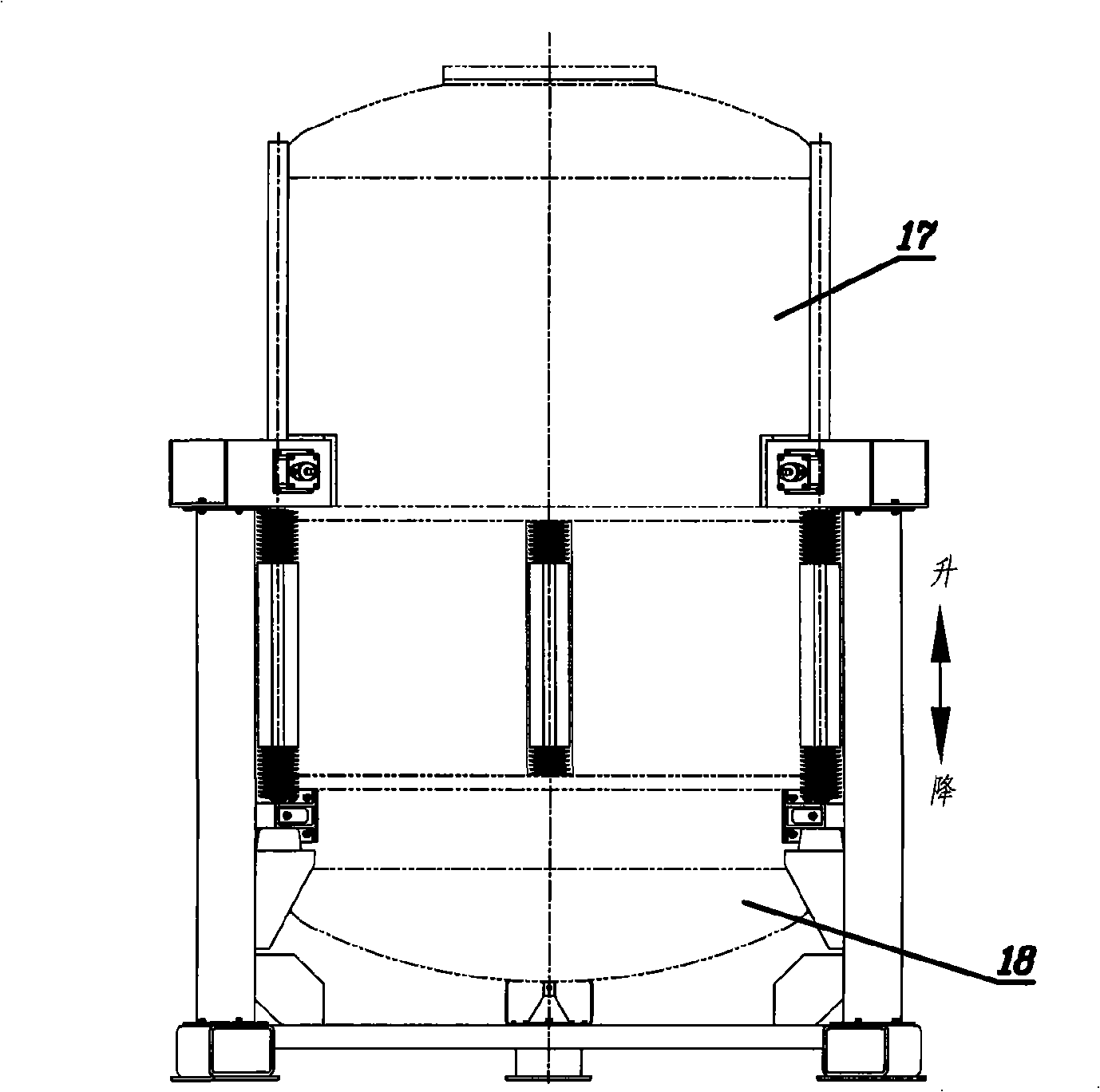

[0025] As shown in Fig. 1 to 5, the present invention has base 4 and screw lifter, and described base 4 is fixedly installed with three columns 2 and these three columns 2 form equilateral triangle distribution on a plane (that is, these three columns are positioned at three sides of equilateral triangle apex position), the upper ends of the three screw lifts are respectively fixedly installed on the fixing seats 1, 24, 11 on the top 2 of the corresponding column, wherein one end of the drive shaft of the first screw lift 21 is equipped with an A brake 23 and the other end is passed through the A brake 23. The first shaft coupling is connected with one end of the first flexible wire shaft 5, the drive shaft of the second screw lift 22 is equipped with a B brake at one end and the other end is connected with an end of the second flexible shaft 16 through the second coupling, and the second shaft coupling is connected with the second flexible shaft 16. One end of the drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com