Electric windshield wiper of automobile and control method thereof

A wiper and electric technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of inconvenient speed adjustment, complex structure and loud noise of wiper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

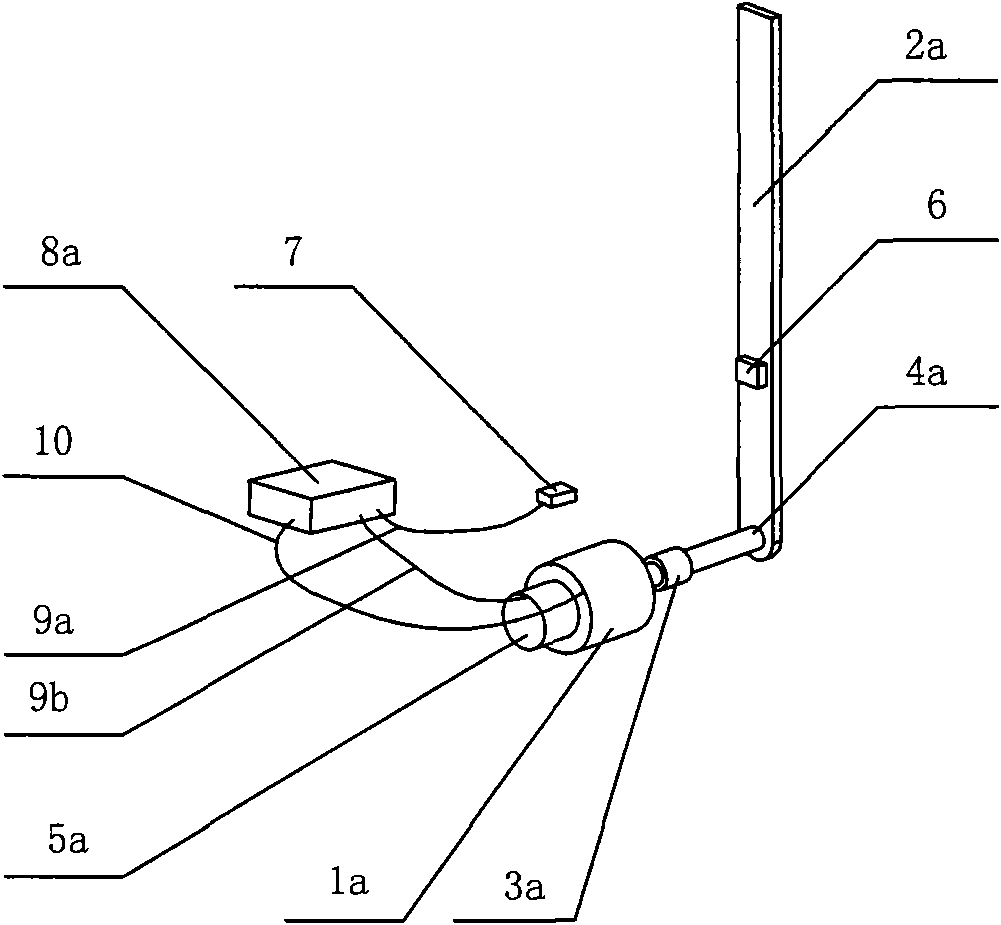

[0120] Refer to the attached drawings, figure 1 It is a schematic diagram of the structure of the electric wiper for an automobile in the first embodiment of the present invention. Such as figure 1 As shown, the automotive electric wiper includes: a first servo motor 1a and a first wiper arm 2a, the output of the first servo motor 1a is connected to the first wiper shaft 4a through a first coupling 3a, and the first wiper shaft A first wiper arm 2a is provided on 4a, and the first wiper arm 2a swings with the rotation of the first wiper shaft 4a.

[0121] A first position detection device 5a is provided on the motor shaft of the servo motor 1a; a magnet 6 is provided on the first wiper arm 2a, and a magnetic induction element is arranged at the corresponding position of the car. In the present invention, the magnetic induction element adopts Hall induction Element 7, the first position detection device 5a and the Hall sensor element 7 output the detected position signal to the fi...

Embodiment 2

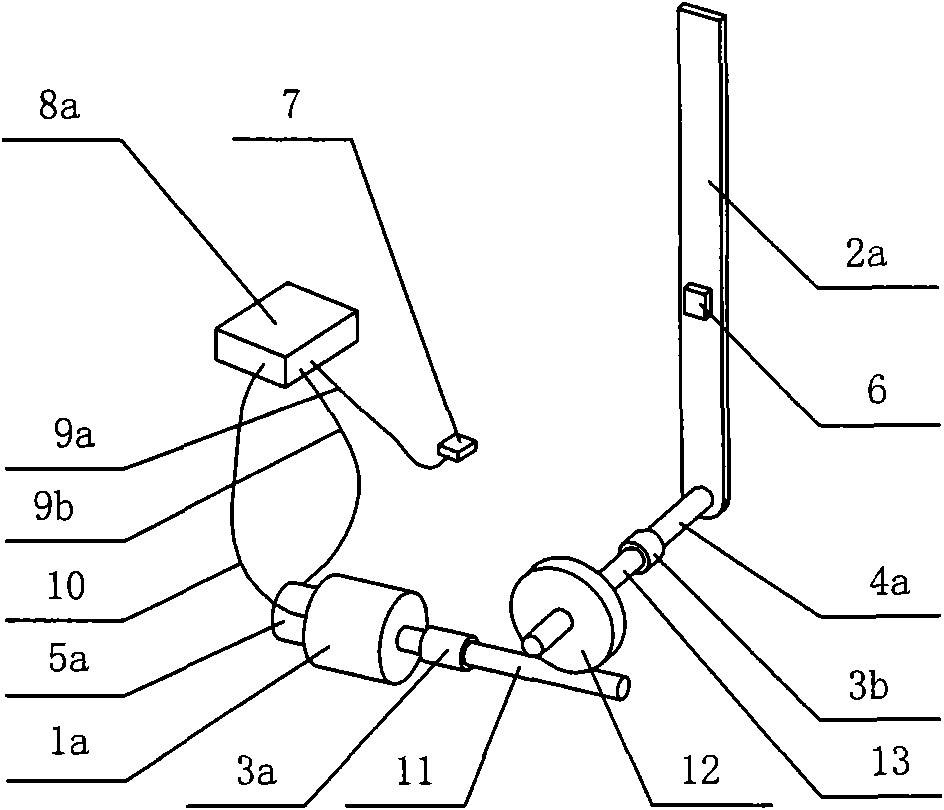

[0127] Such as figure 2 As shown, the difference from the first embodiment is that the electric wiper also includes a reducer. The servo controller 8a controls the operation of the first servo motor 1a. The motor is connected to the worm 11 through the first coupling 3a to drive the worm 11 to rotate, and the worm 11 drives the worm wheel 12 to rotate. The worm shaft 13 communicates with the first through the second coupling 3b. The wiper shaft 4a is connected to drive the first wiper shaft 4a to rotate. The reducer used here is a worm gear reducer. Cylindrical gear reducers, bevel gear reducers, planetary gear reducers, etc. can also be used. The electric wiper is a single wiper structure wiper with simple structure. The servo controller can control the wiper to achieve any swing angle from 0° to 180°, so it can not only replace the existing single wiper structure wiper, but also replace the existing double wiper. Wiper blades for scraping structure.

Embodiment 3

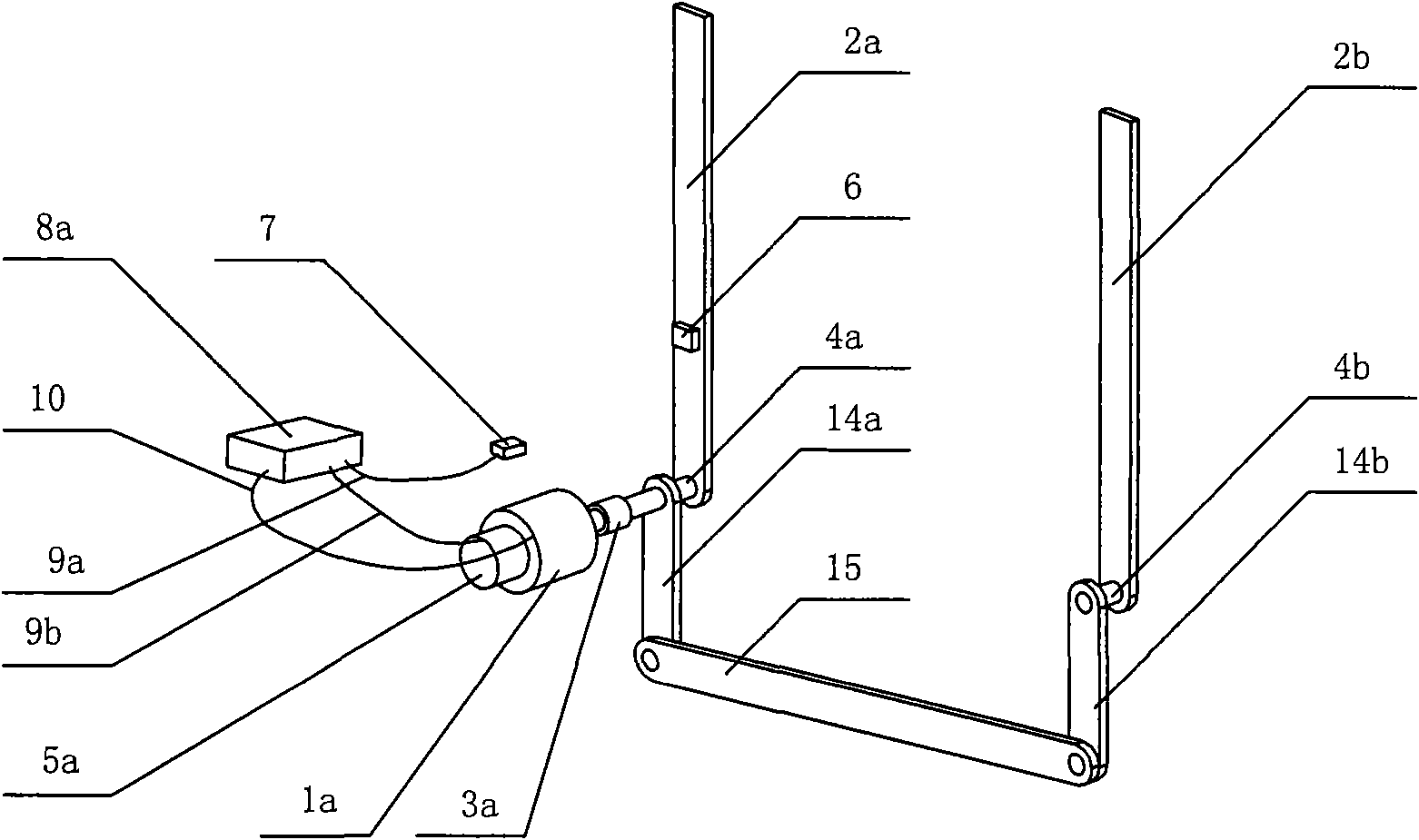

[0129] Such as image 3 As shown, the difference from the first embodiment is that a first crank 14a is sleeved on the first wiper shaft 4a of the electric wiper, the first crank 14a is connected to the second crank 14b through the synchronization rod 15, and the second crank 14b is provided on the There is a second wiper shaft 4b, and the second wiper shaft 4b rotates and drives the second wiper arm 2b fixed on it to swing. There is no reducer between the motor and the wiper shaft of the automobile wiper, and they are directly connected through a coupling. This can simplify the structure of the wiper, but requires the motor to provide greater torque.

[0130] In this embodiment, the method for controlling the electric wiper of an automobile includes the following steps:

[0131] Step 1: The first wiper arm 2a swings in the direction of the Hall sensor element 7 driven by the servo motor 1a. Set the rotation direction of the servo motor to the forward direction and the swing direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com