Device for automatic controlling final position of moving element

A technology of automatic control device and moving parts, applied in the direction of control using feedback, can solve the problems of high frequency conversion cost, high motor power, high cost, and achieve the effects of good performance, low control accuracy and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

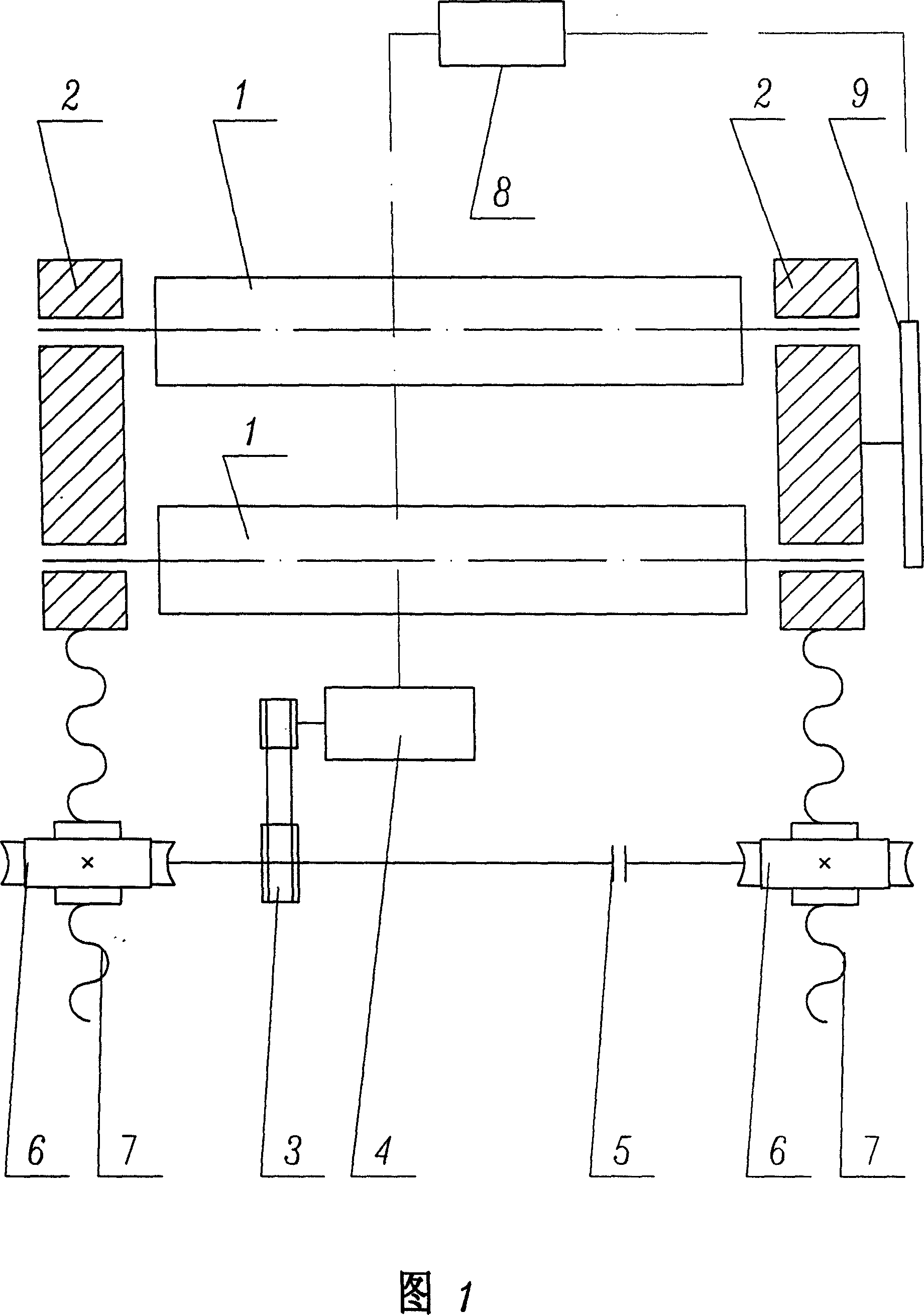

Embodiment 1

[0018] As shown in Figure 1, it is an embodiment of using the automatic control device for the final position of the moving parts for the horizontal movement of the lower roller of the horizontally adjustable roller plate bending machine. The transmission device is a sprocket 3, a connecting shaft and a flange connector 5, a worm gear pair 6, and a screw nut pair 7; the moving parts are the lower roller bearing housing 2 and the lower roller 1. The displacement sensor is located at the bearing seat 2 of the lower roller. The lower roller moves horizontally on the guide rail of the bed corresponding to the upper roller, and the double-speed motor 4 drives the lower roller bearing housing 2 and the The lower roller 1 moves horizontally, and the motor frequency conversion module is set in the control system 8. The size of the motor frequency conversion module is configured according to the low-speed pole power of the two-speed motor 4. The horizontal movement of the lower roller...

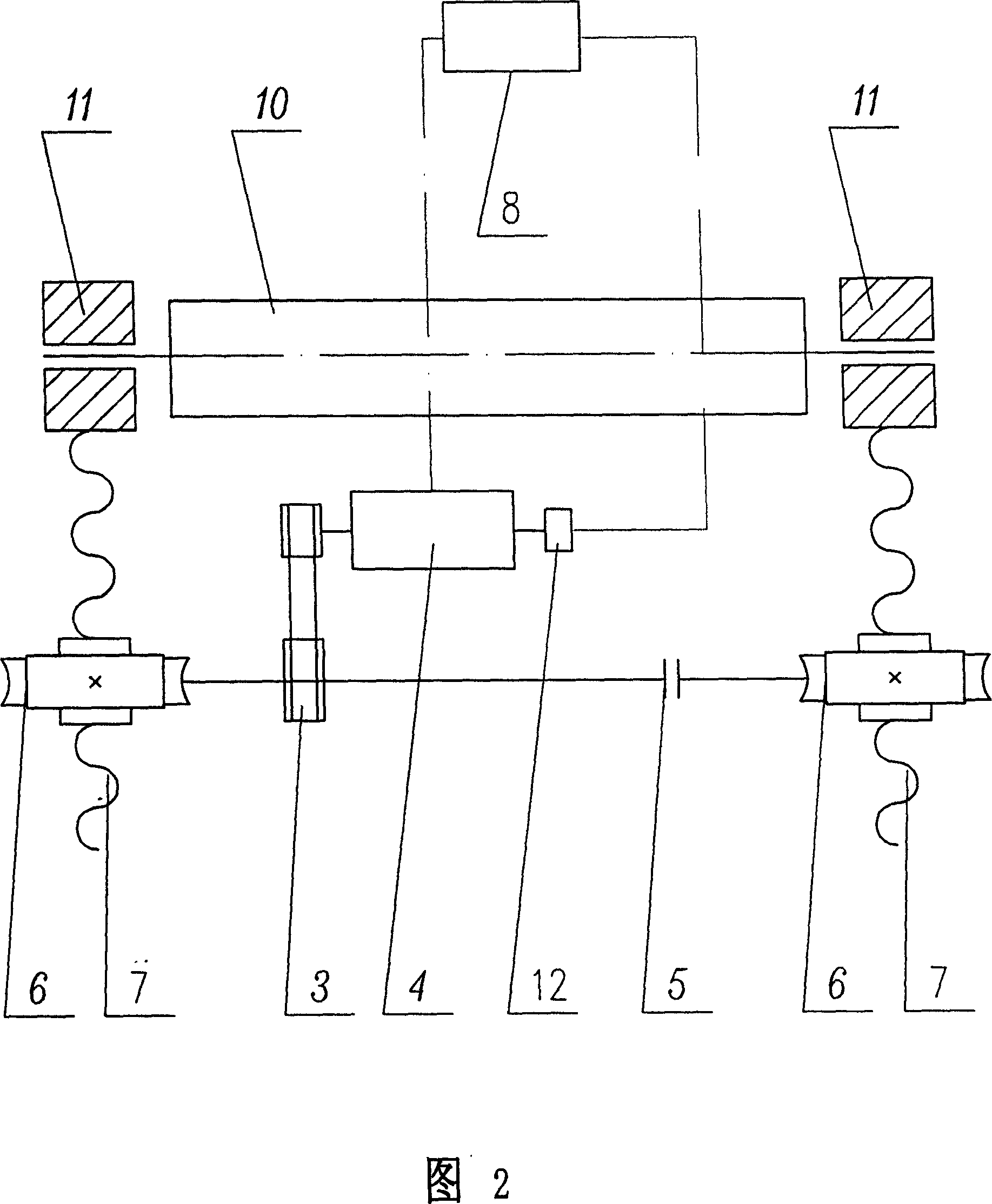

Embodiment 2

[0020] As shown in Figure 2, it is an embodiment of using the automatic control device for the final position of the moving parts for the mechanical lifting movement of the upper roller of the roller plate bending machine. The transmission device is a sprocket 3, a connecting shaft and a flange connector 5, a worm gear pair 6, and a screw nut pair 7; the moving parts are the upper roller bearing housing 11 and the upper roller 10. The upper roller moves up and down corresponding to the lower roller, and the double-speed motor 4 drives the upper roller bearing seat 11 and the upper roller 10 to move up and down through the sprocket 3, the connecting shaft and the flange connector 5, the worm gear pair 6, and the screw nut pair 7 , the displacement sensor (rotary encoder 12) is set on the shaft of the two-speed motor 4, the size of the motor frequency conversion module in the control system 8 is configured according to the low-speed pole configuration of the two-speed motor 4, an...

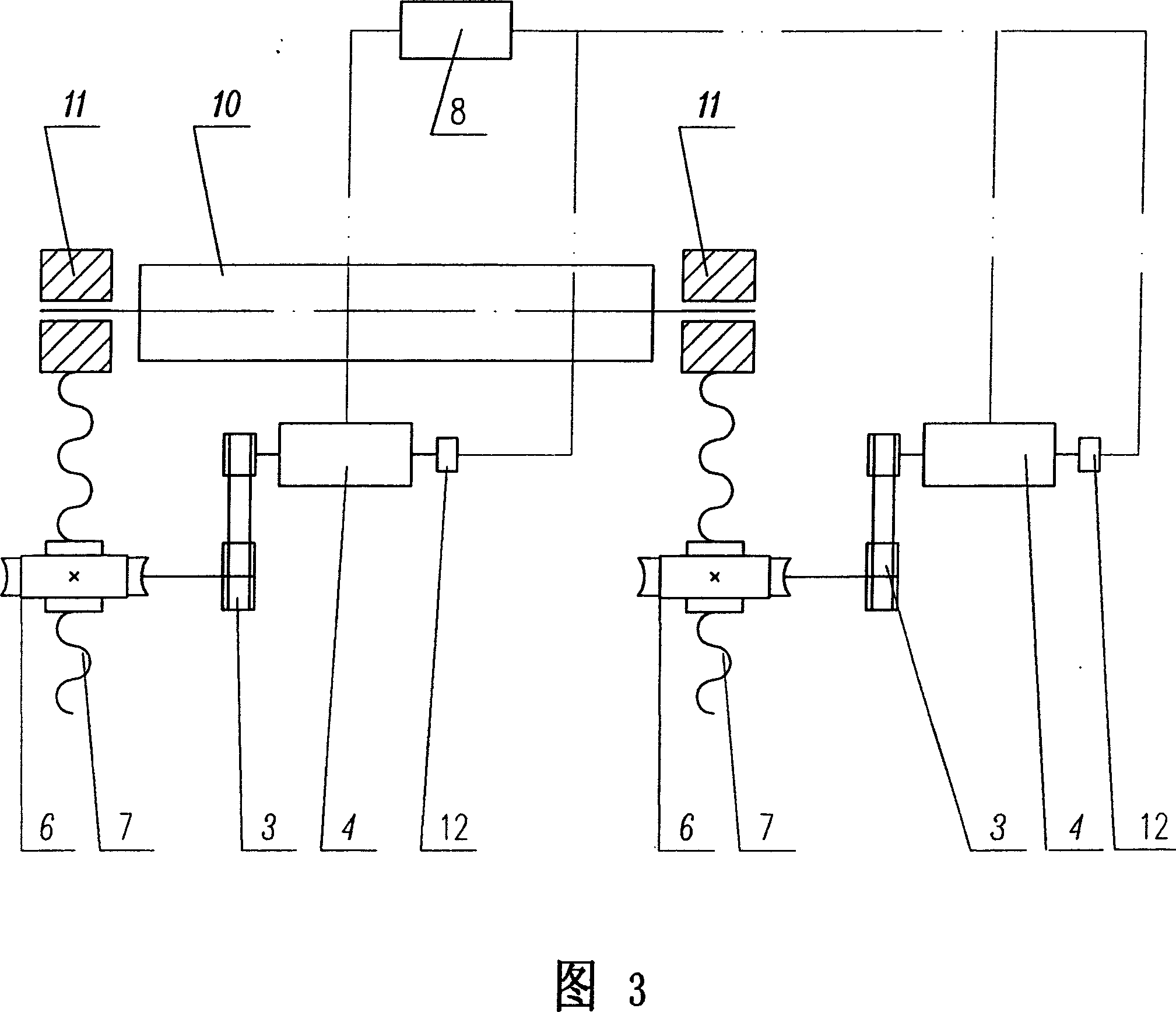

Embodiment 3

[0022] As shown in Figure 3, it is an embodiment of using the automatic control device for the final position of the moving part for the mechanical lifting movement of the upper roller of the roller plate bending machine. The transmission device is a sprocket 3, a connecting shaft and a flange connector 5, a worm gear pair 6, and a screw nut pair 7; the moving parts are the upper roller bearing housing 11 and the upper roller 10. The control system 8 uses the control device described in Embodiment 2 to control the upper roller bearing housings 11 at both ends of the upper roller 10, the displacement sensor (rotary encoder 12) is arranged on the shaft of the two-speed motor 4, and the control system 8 controls the upper roller 10. The final positions of the upper roll bearing housings 11 at both ends meet the requirements of the set value with a certain accuracy. Because the upper roller chocks 11 at the two ends of the upper roller 10 control the lifting respectively, the worm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com