Ship lifting device

A kind of technology of ship-carrying, left-right, applied in the direction of lifting device, vertical lifting of ship machinery, construction, etc., can solve the problems of poor safety, low transmission efficiency, complex transmission mechanism, etc., to achieve convenient control, high transmission efficiency, and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

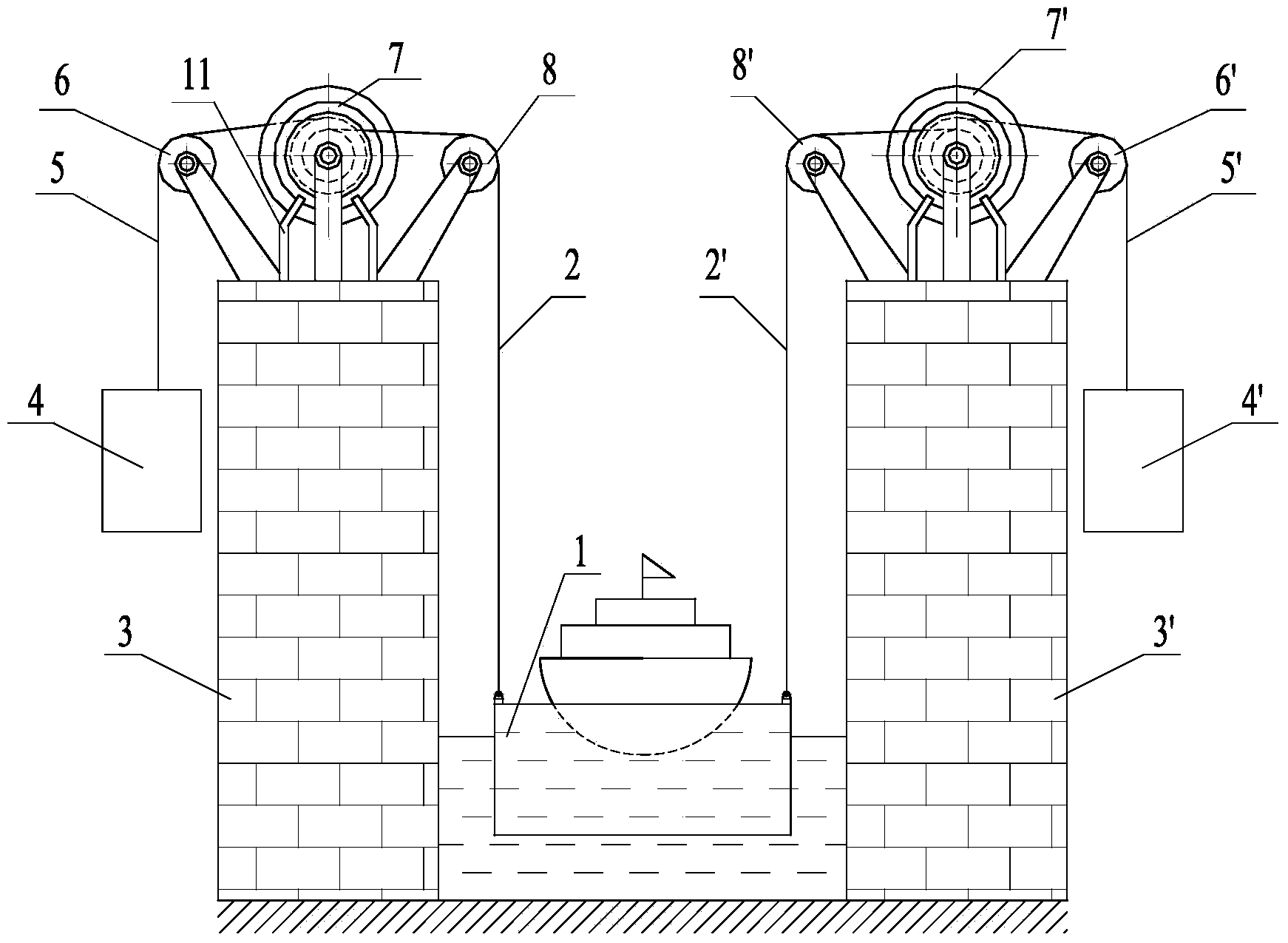

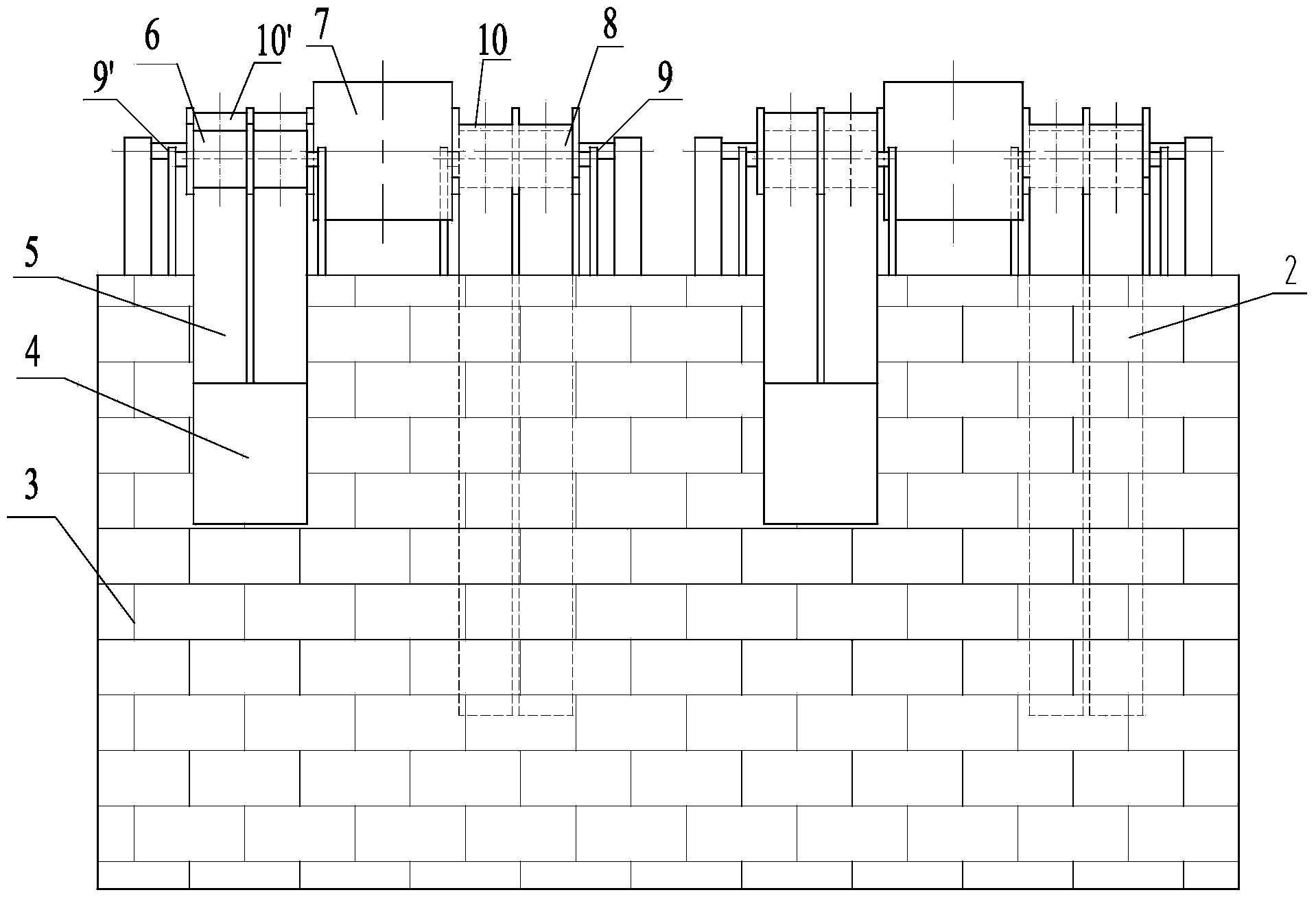

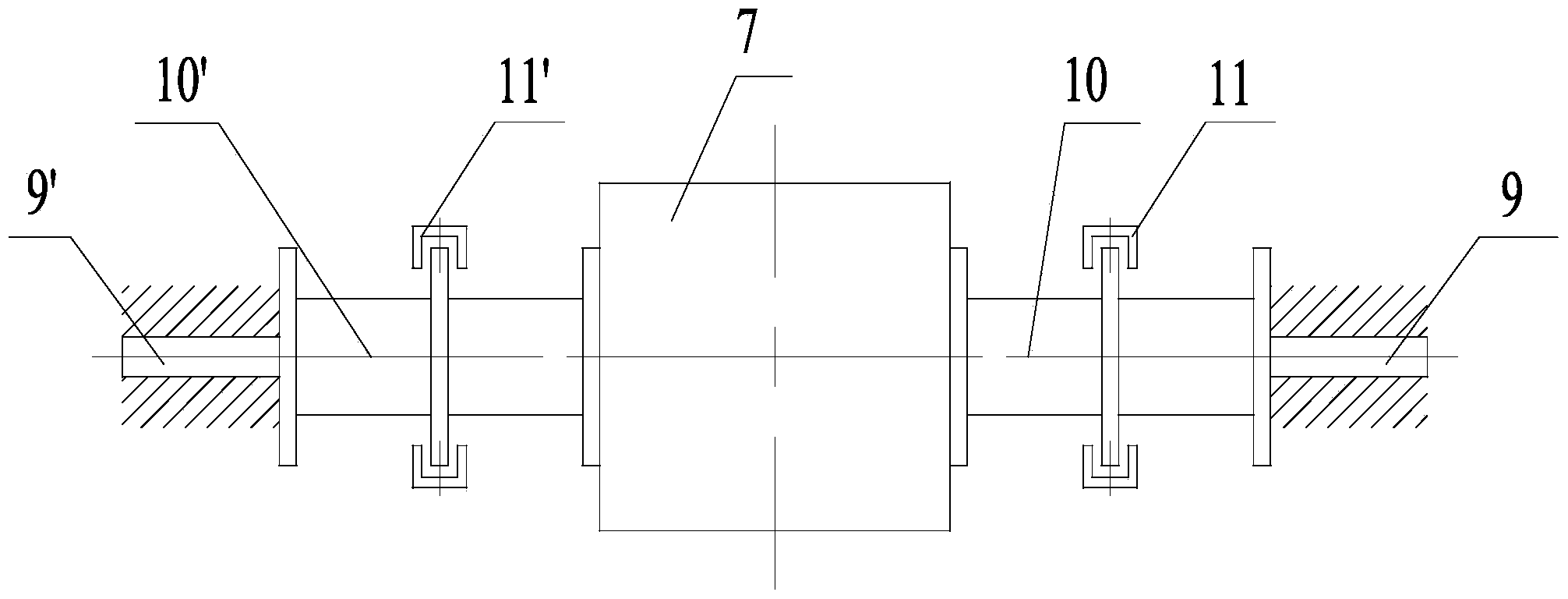

[0010] like figure 1 As shown, the downstream incoming ship is driven into the ship-bearing compartment 1 in the dam, and the left and right outer rotor motors 7, 7' are started, and the front drum 10 of the left outer rotor motor 7 rotates counterclockwise, while the front drum 10 of the right outer rotor motor 7' rotates counterclockwise. The drum rotates clockwise, and the ship-carrying box 1 and the ship are raised to the required height through the left and right ship-carrying car belts 2, 2', and the left and right counterweights 4, 4' are lowered by the counterweight at the same time; The belts on the heavy side are used in multiple sets. When one of them breaks, the other one continues to work normally, waiting for maintenance, so as to avoid the sudden drop of the counterweight or the loss of balance of the carrier box, which will cause safety accidents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com