Steel fiber dispersing machine for preparing fiber concrete

A fiber-reinforced concrete and steel fiber technology, applied in solid separation, screens, grids, etc., can solve the problems of low dispersion efficiency, time-consuming and laborious, and damage to steel fibers, so as to improve dispersion efficiency and avoid bending or damage , to avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

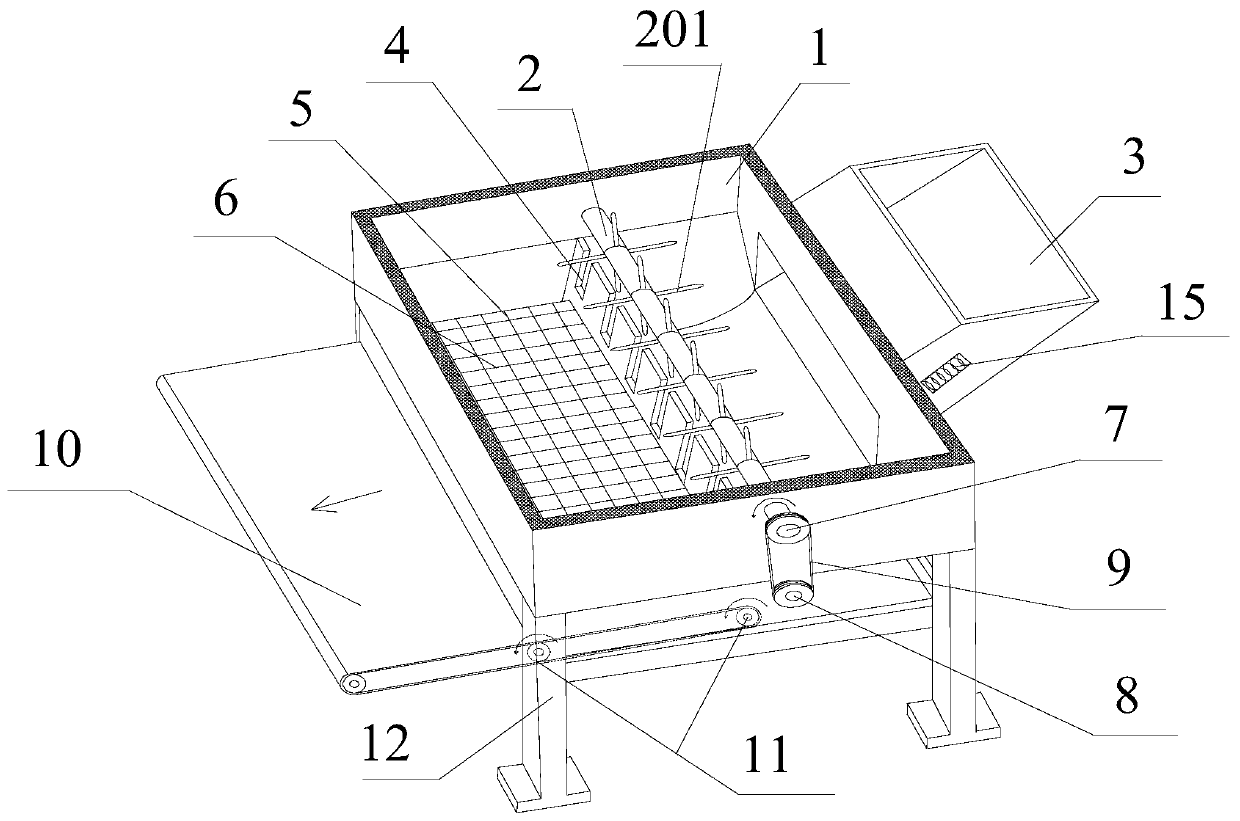

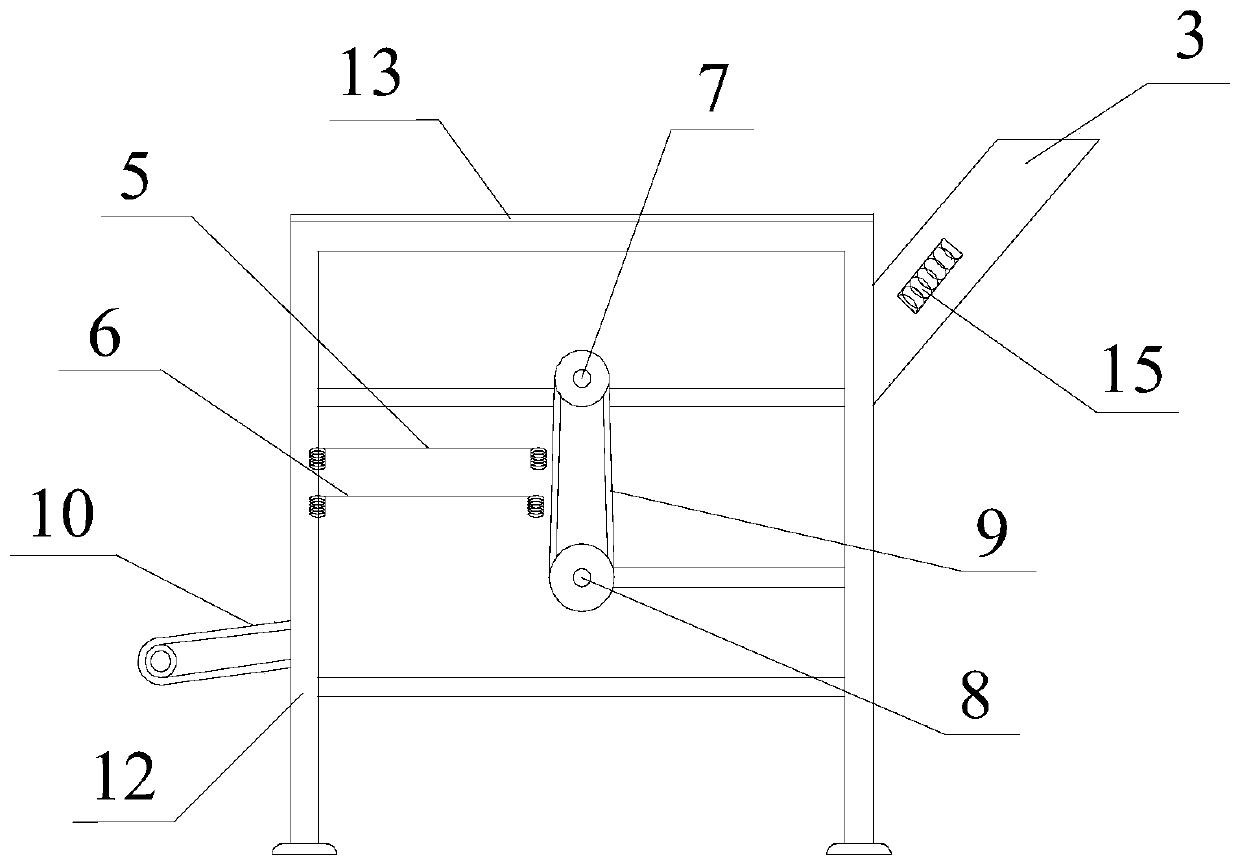

[0035] like Figure 1 ~ Figure 4 As shown, it includes a silo 1 fixed on a bracket 12, a feed hopper 3 is provided on the side wall of the silo 1, a vibrating assembly and a vertically placed partition are included, and the partition divides the material The interior of the warehouse 1 is divided into a feeding chamber and a dispersion chamber. The output port of the feed hopper 3 is connected to the feeding chamber. A feeding device 2 is provided in the feeding chamber, and a discharge port is provided at the bottom of the dispersion chamber. The vibration assembly Fixed on the discharge port; the pusher 2 includes a rotating shaft 7 that is arranged on the wall of the dialing cavity, and a plurality of dialing units are arranged on the outer peripheral wall along the axis of the rotating shaft 7, and the opening on the dividing plate There are a plurality of shifting tooth slots 4 corresponding to the shifting unit, each of which is composed of a plurality of shifting teeth ...

Embodiment 2

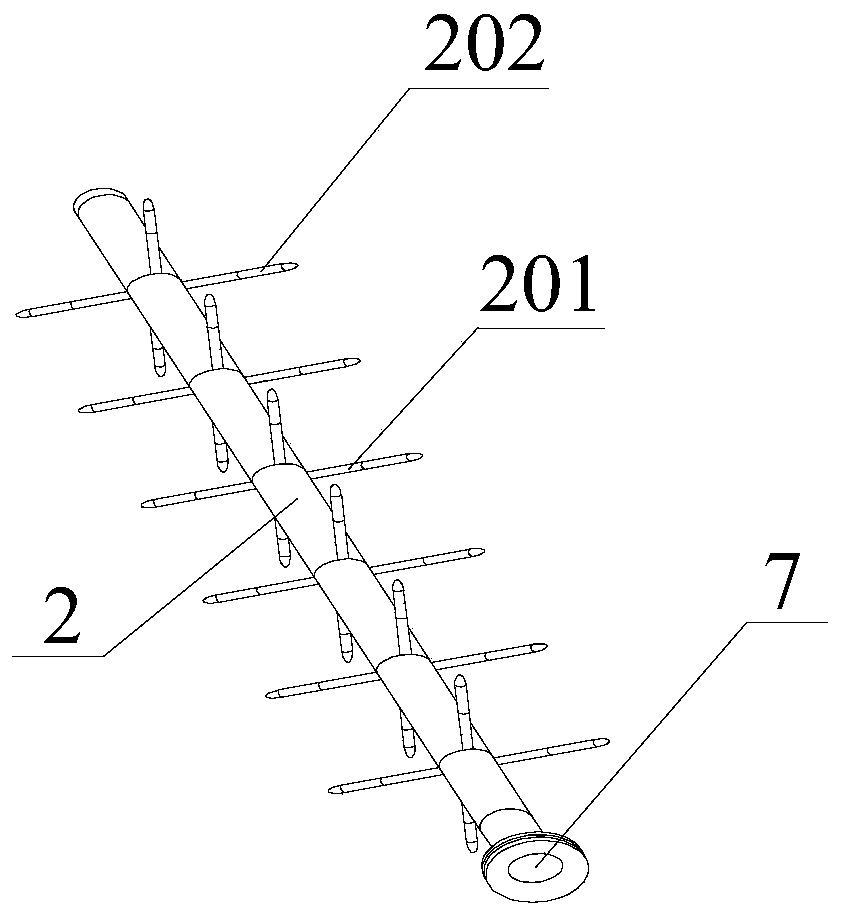

[0043] like Figure 3 ~ Figure 4 As shown, on the basis of Embodiment 1, this embodiment further defines the shifting tooth 201. The shifting tooth 201 is in the shape of a round rod, and one end of the central axis 203 is fixed on the top of the shifting tooth 201. On the outer end face, the roller 202 is sleeved on the central shaft 203 , and the other end of the central shaft 203 is fixed with a tooth tip 204 , and the outer diameter of the tooth tip 204 decreases outward along the radial direction of the rotating shaft 7 .

[0044] The shifting tooth 201 is in the shape of a round rod, and is made of a wear-resistant metal rod, and a central shaft 203 is set on the outer end face of the shifting tooth 201, and a roller 202 is set on the central shaft 203, and the tooth tip 204 is fixed on the central shaft On the end of 203, the roller 202 can rotate freely; in the process that a single shifting tooth 201 drives the steel fiber to transfer from the shifting chamber to the ...

Embodiment 3

[0046] like Figure 5 ~ Figure 6 As shown, the vibrating assembly in this embodiment includes a first vibrating screen 5 and a second vibrating screen 6 placed sequentially from top to bottom, the first vibrating screen 5 includes a rectangular first vibrating screen frame 501, and the second vibrating screen 6 includes a rectangular second vibrating screen frame 601, on the first vibrating screen frame 501 is provided with a plurality of first screen bars 502, and each of the first screen bars 502 and the long side of the first vibrating screen frame 501 Equal length, a plurality of second screen bars 602 are provided on the second vibrating screen frame 601, and each of the second screen bars 602 is equal to the long side of the second vibrating screen frame 601, the first screen bar 502 and the second sieve bars 602 are perpendicular to each other, and a plurality of through holes aligned with the blind holes 504 are opened on the two short sides of the second vibrating scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com