Sand mill

A sand mill and frame technology, applied in the field of pigment processing, can solve the problems of poor dispersion effect, less pigment distribution, high temperature of sand mill, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

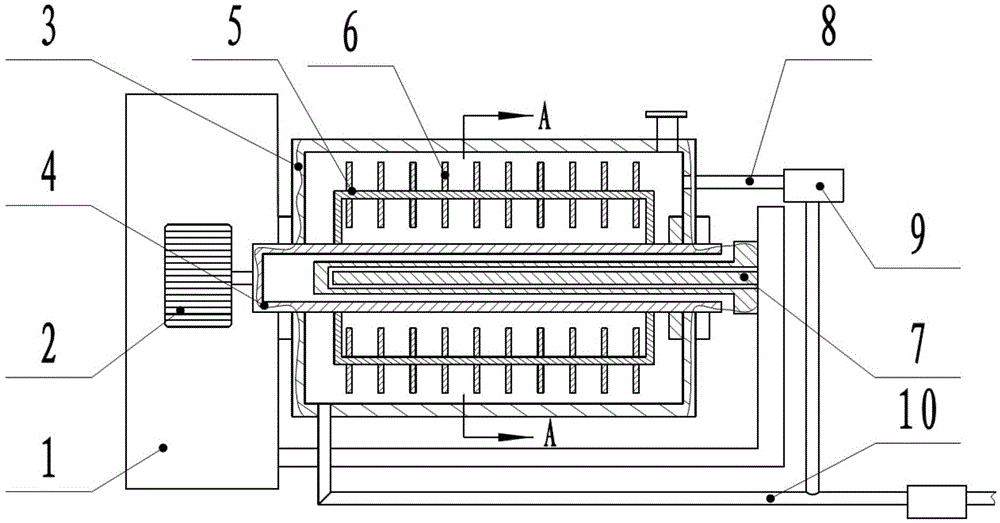

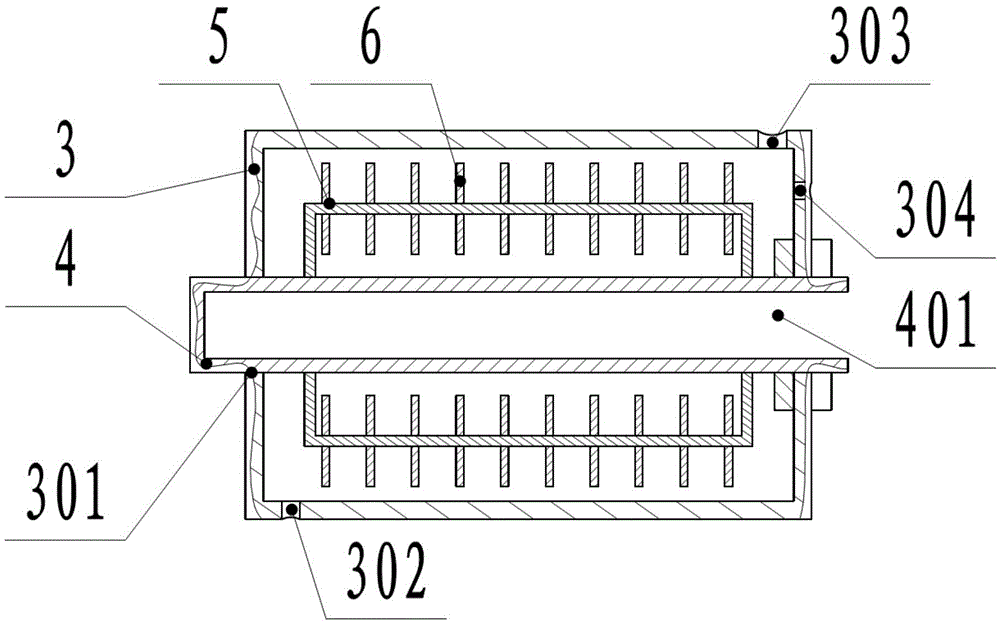

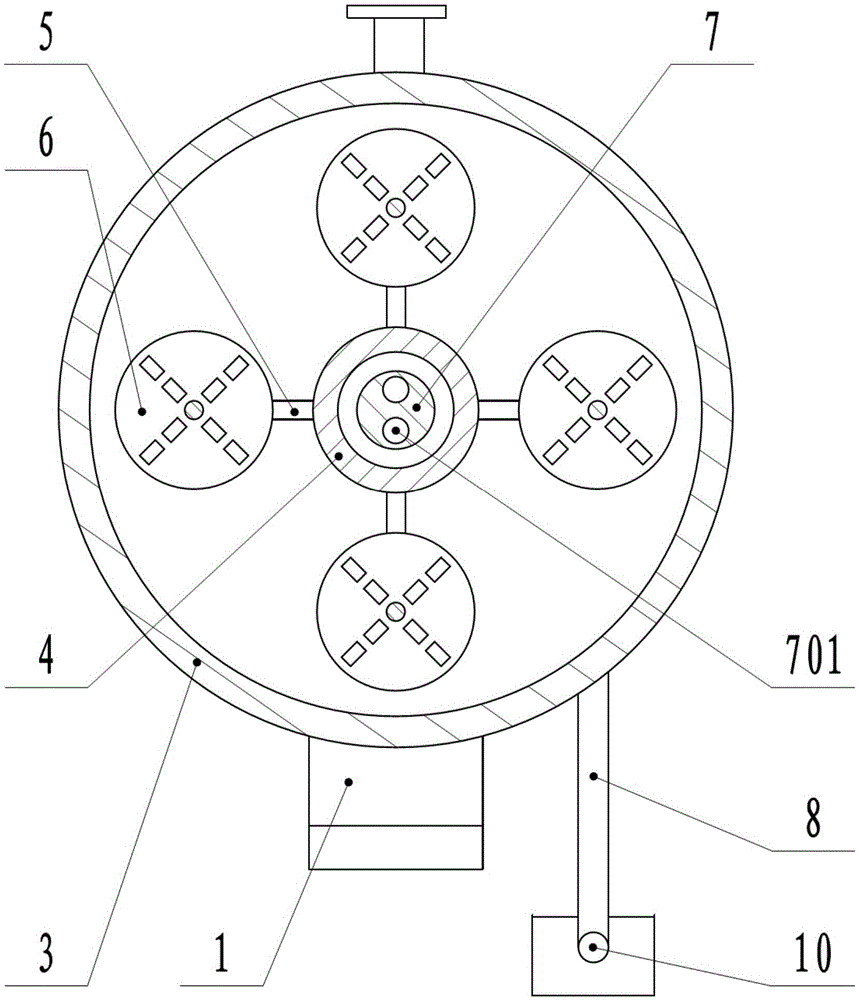

[0017] A sand mill includes a frame 1, a motor 2, a grinding cylinder 3, a main shaft 4, four dispersing disc supports 5, forty dispersing discs 6, a cooling core 7 and a return pipe 8.

[0018] The motor 2 is fixedly connected to the frame 1; the grinding cylinder 3 is arranged on the right side of the motor 2, and is fixedly connected with the frame 1. There is a through hole 301 in the center of the grinding cylinder 3, a feeding port 302 on the left side of the bottom, and a feeding port 302 on the right side of the top. There is a discharge port 303, and an overflow port 304 is provided on the upper part away from the motor 2. One end of the return pipe 8 is connected to the overflow port 304, and the other end is connected to the feed port 302 through the feed pipe 10. The feed pipe 10 is provided with There is a pressurization device, and a overflow valve 9 is provided on the return pipe 8 .

[0019] The main shaft 4 and the grinding cylinder 3 are concentrically arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com