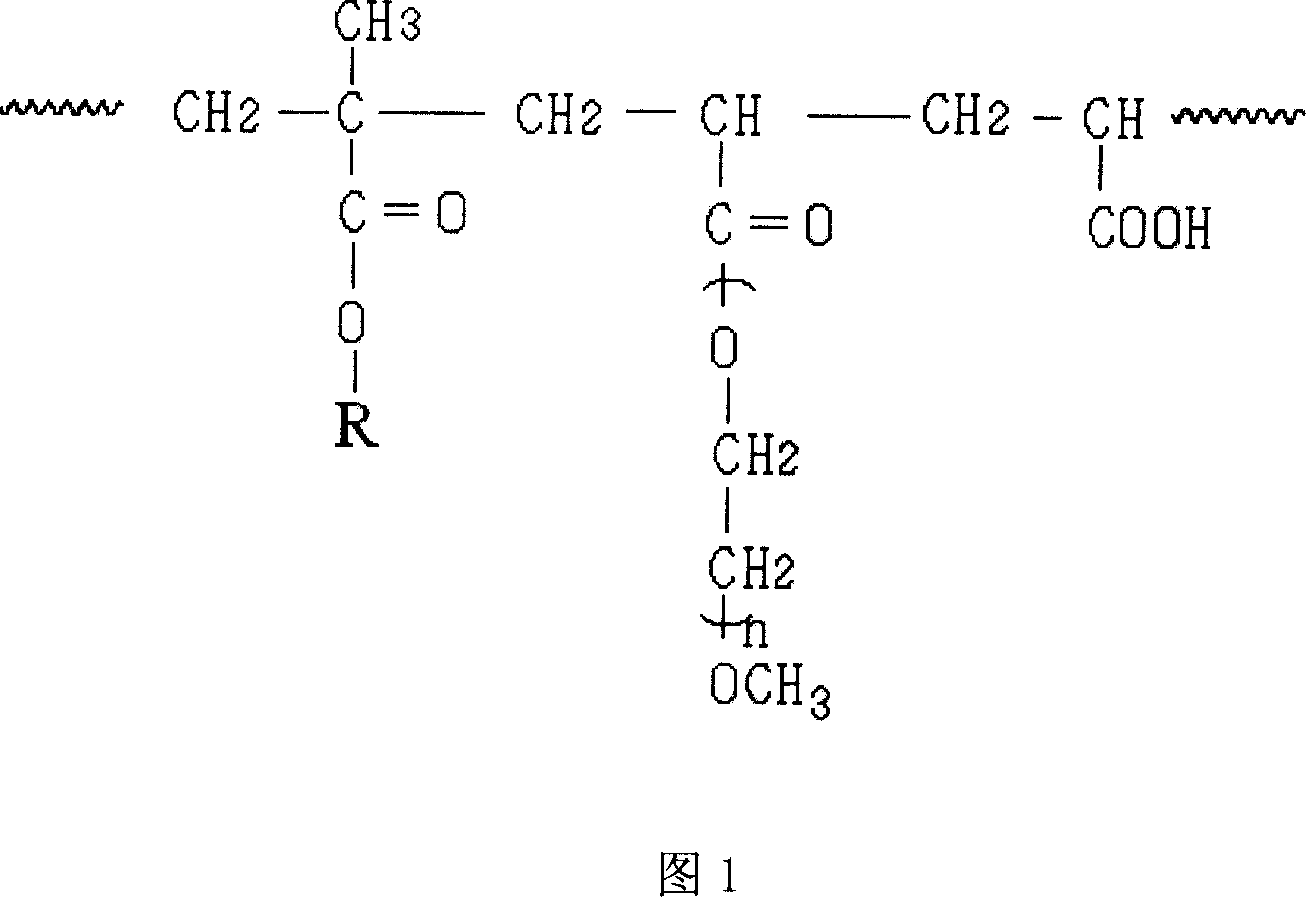

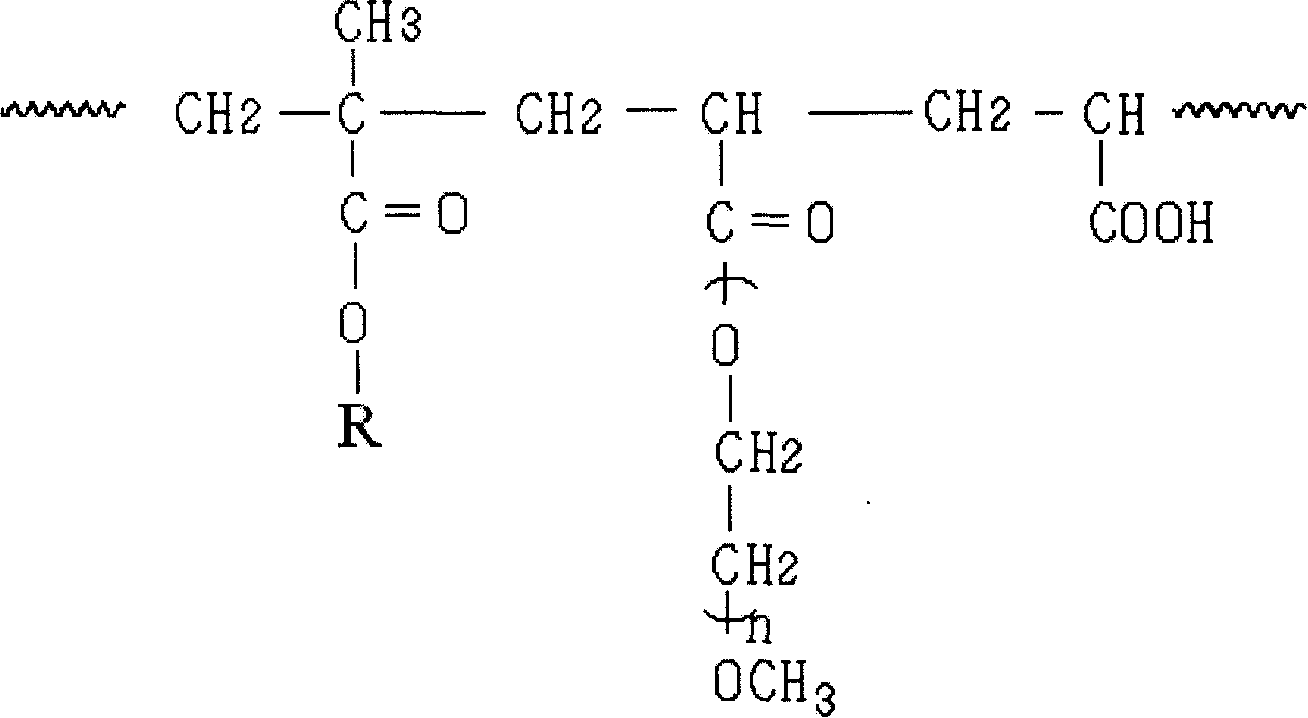

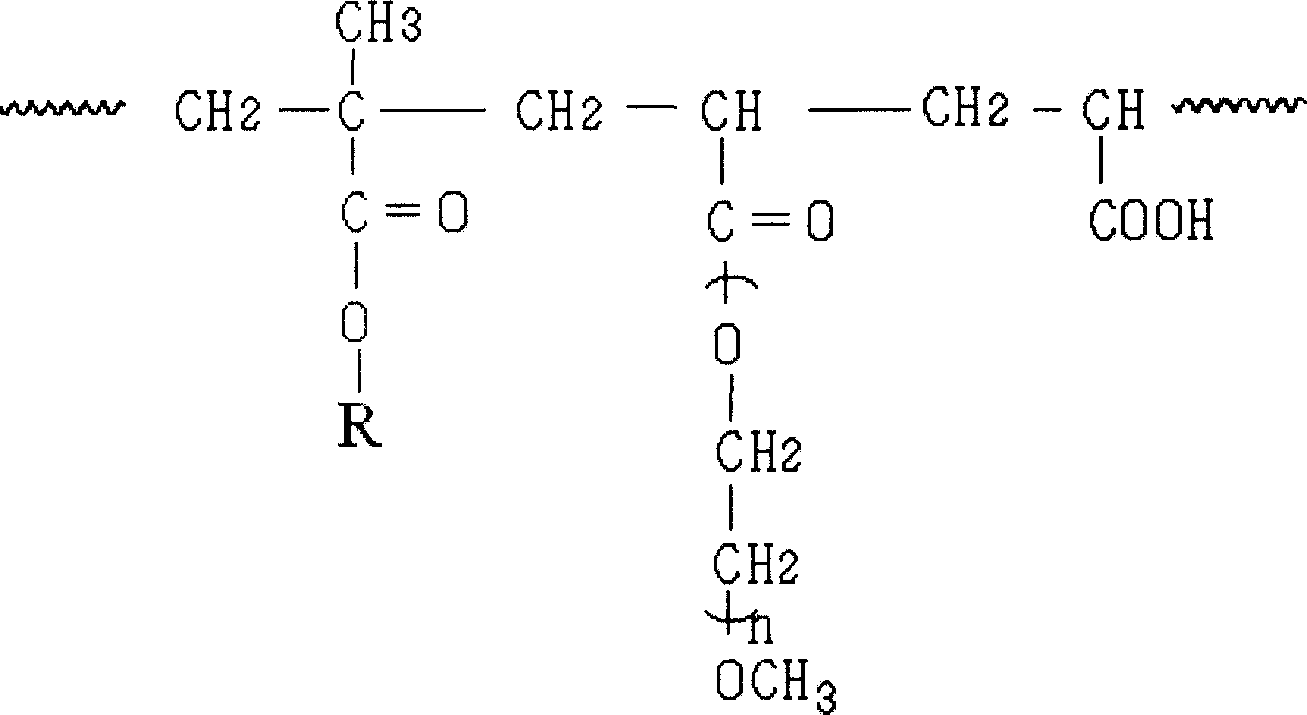

High molecular dispersant agent and its preparing method

A polymer dispersant, a certain amount of technology, used in chemical instruments and methods, coating, transportation and packaging, etc., can solve problems such as unsatisfactory dispersion effect, achieve good storage stability and fluidity, improve coating performance, The effect of high dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Add 14 parts by weight (parts by weight, the same below) of dimethyl polyethylene glycol acrylate single body, and then add 0.4 parts of isopropanol and 0.1 parts of methanol mixed solution.

[0022] 2. Dissolve a 1.5% initiator in 0.05 part of methanol, and add it into the constant pressure dropping funnel. Then 0.75 parts of acrylic acid and 1 part of butyl methacrylate were mixed into another constant pressure dropping funnel. Begin to blow nitrogen, and heat, stir. Since it is a solution system reaction, the temperature is kept constant at 70°C. Within 30 minutes after the dropwise addition of the mixed monomers was completed, the dropwise addition of the initiator was completed. After the initiator was added dropwise, reacted for 2 hours to end the reaction. The product was taken out and placed in a pear-shaped flask, and subjected to rotary evaporation to obtain a crude product.

[0023] 3. The obtained crude product was dissolved in tetrahydrofuran (THF),...

Embodiment 2

[0026] 1. Add 15 parts by weight (parts by weight, the same below) of dimethyl polyethylene glycol acrylate single body, and then add 0.4 parts of isopropanol and 0.1 parts of methanol mixed solution.

[0027] 2. Dissolve a 2.0% initiator in 0.05 part of methanol, and add it into the constant pressure dropping funnel. Then 0.80 parts of acrylic acid and 1 part of methyl methacrylate were mixed and added to another constant pressure dropping funnel. Begin to blow nitrogen, and heat, stir. Since it is a solution system reaction, the temperature is kept constant at 75°C. Within 30 minutes after the dropwise addition of the mixed monomers was completed, the dropwise addition of the initiator was completed. After the initiator was added dropwise, reacted for 1.5 hours to end the reaction. The product was taken out and placed in a pear-shaped flask, and subjected to rotary evaporation to obtain a crude product.

[0028] 3. The obtained crude product was dissolved in tetrahydrof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com