Thin layer graphene-based dispersion slurry, and preparation method and application thereof

A technology of thin-layer graphene and dispersion slurry, which is applied in the field of nanotechnology and coatings, and can solve problems such as poor compatibility and difficult dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

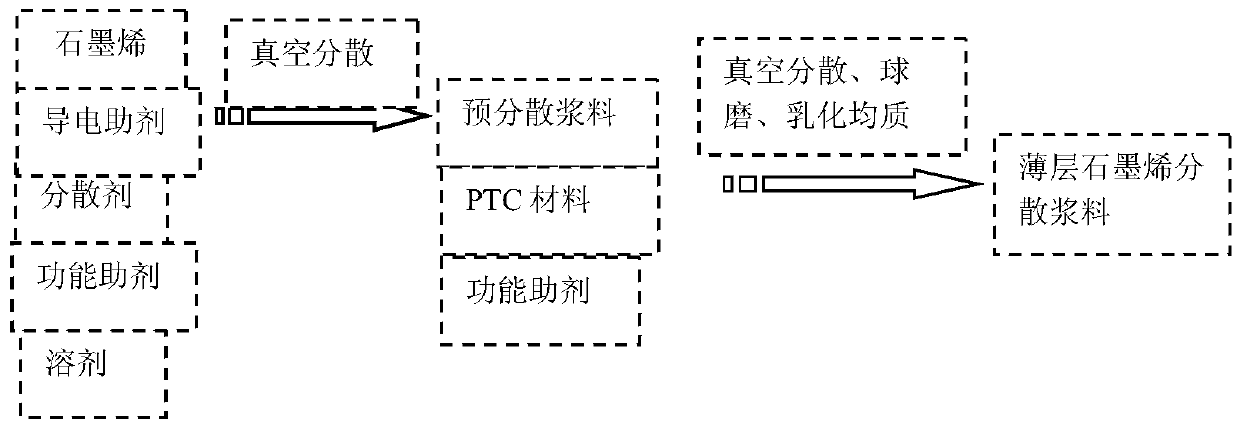

Method used

Image

Examples

Embodiment 1

[0047] A thin-layer graphene-based dispersion slurry added to coating coatings, including the following raw materials in parts by weight, 8 parts of high-quality thin-layer graphene powder, 2 parts of carbon nanotube powder, 0.3 parts of polyvinylpyrrolidone, 0.2 parts of sodium carboxymethyl cellulose, barium titanate (0.4 mol% doped niobium Ba 0.9 Sr 0.1 TiO 3 ) 10 parts, hydrophilic treated polyethylene powder 5 parts, anti-settling agent BYK420 0.5 parts, wetting agent BYK191 0.5 parts, KH550 0.5 parts, defoamer TEGO 902w, deionized water balance.

[0048] A thin-layer graphene-based dispersion slurry added to coating paint, comprising the following steps:

[0049] 1) Add graphene powder, carbon nanotube powder, polyvinylpyrrolidone, sodium carboxymethyl cellulose, TEGO 902w, and deionized water into a vacuum stirring disperser, and stir at 1500 rpm for about 2 hours to disperse evenly, forming pre-dispersion;

[0050] 2) In the pre-dispersion liquid, add KH550, BYK191...

Embodiment 2

[0053] A thin-layer graphene-based dispersion slurry added to coating coatings, including the following raw materials in parts by weight, 5 parts of high-quality thin-layer graphene powder, 2 parts of carbon nanotube powder, 3 parts of conductive carbon black, 2 parts of polyvinylidene fluoride, barium titanate (0.4mol% doped niobium Ba 0.9 Sr 0.1 TiO 3 ) 10 parts, DISPERBYK2000 0.5 parts, TEGO Airex 900, KH550 0.5 parts, fumed silica 0.5 parts, N-methylpyrrolidone balance.

[0054] A kind of preparation method of the thin-layer graphene dispersion slurry that is used for anticorrosion coating, comprises the following steps:

[0055] 1) Add graphene powder, carbon nanotube powder, carbon black powder, TEGO Airex 900, DISPERBYK2000 respectively into the vacuum stirring disperser, carry out vacuum 1500rpm stirring for about 2 hours to disperse evenly, and form a pre-dispersion;

[0056] 2) Fumed silica, KH550, polyvinylidene fluoride, barium titanate (0.4mol% doped niobium Ba...

Embodiment 3

[0059] A thin-layer graphene-based dispersion slurry added to coating coatings, including the following raw materials in parts by weight, 1 part of high-quality thin-layer graphene powder, 1 part of Ketjen black powder, 1 part of polypropylene micropowder, Barium titanate (0.4mol% niobium-doped Ba 0.9 Sr 0.1 TiO 3 ) 1 part, DISPERBYK2200 0.5 part, KH560 0.5 part, Anti-terra-204 0.5 part, N, N-dimethylformamide balance.

[0060] A thin-layer graphene-based dispersion slurry added to coating paint, comprising the following steps:

[0061] 1) Add graphene powder, carbon black powder, DISPERBYK2200, Anti-terra-204, N, N-dimethylformamide respectively into the vacuum stirring disperser, and carry out vacuum stirring at 1500rpm for about 2 hours to disperse evenly and form a pre- Dispersions;

[0062] 2) Add KH560, TEGO Airex 900, polypropylene micropowder, barium titanate (0.4mol% niobium-doped Ba 0.9 Sr 0.1 TiO 3 ) and other remaining components, continue stirring under vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com