Membrane electrode for fuel cell and preparation method thereof

A fuel cell and membrane electrode technology, which is applied to fuel cell components, fuel cells, battery electrodes, etc., can solve the problems of decreased battery performance, insufficient dispersion, and long operating time, so as to shorten the dispersion time and improve the utilization rate. And, the effect of improving the dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 1g of Pt / C catalyst (Pt mass fraction is 40%), add deionized water, isopropanol, perfluorosulfonic acid resin solution, 2g, 3g, 8.5g, 3g of ethylene glycol in sequence, and disperse at 3000rpm 10min. Dissolve 0.5g of ammonium bicarbonate in 2g of water, stir with a magnetic stirrer for 20min until the ammonium bicarbonate is completely dissolved, then add all the solution into the above slurry and disperse at 8000rpm for 0.5h, and finally disperse at a low speed of 3000rpm for 20min until the slurry Air bubbles in the material are completely removed to obtain a slurry of the present invention.

Embodiment 2

[0032] Take 1g of Pt / C catalyst (Pt mass fraction is 40%), add deionized water, isopropanol, perfluorosulfonic acid resin solution, glycerol, simethicone oil 4g, 3g, 8.5g, 3g, 0.05g, the resulting mixture was dispersed at 8000rpm for 0.5h, and finally at a low speed of 3000rpm for 20min until the air bubbles in the slurry were completely removed to obtain a slurry of the present invention.

Embodiment 3

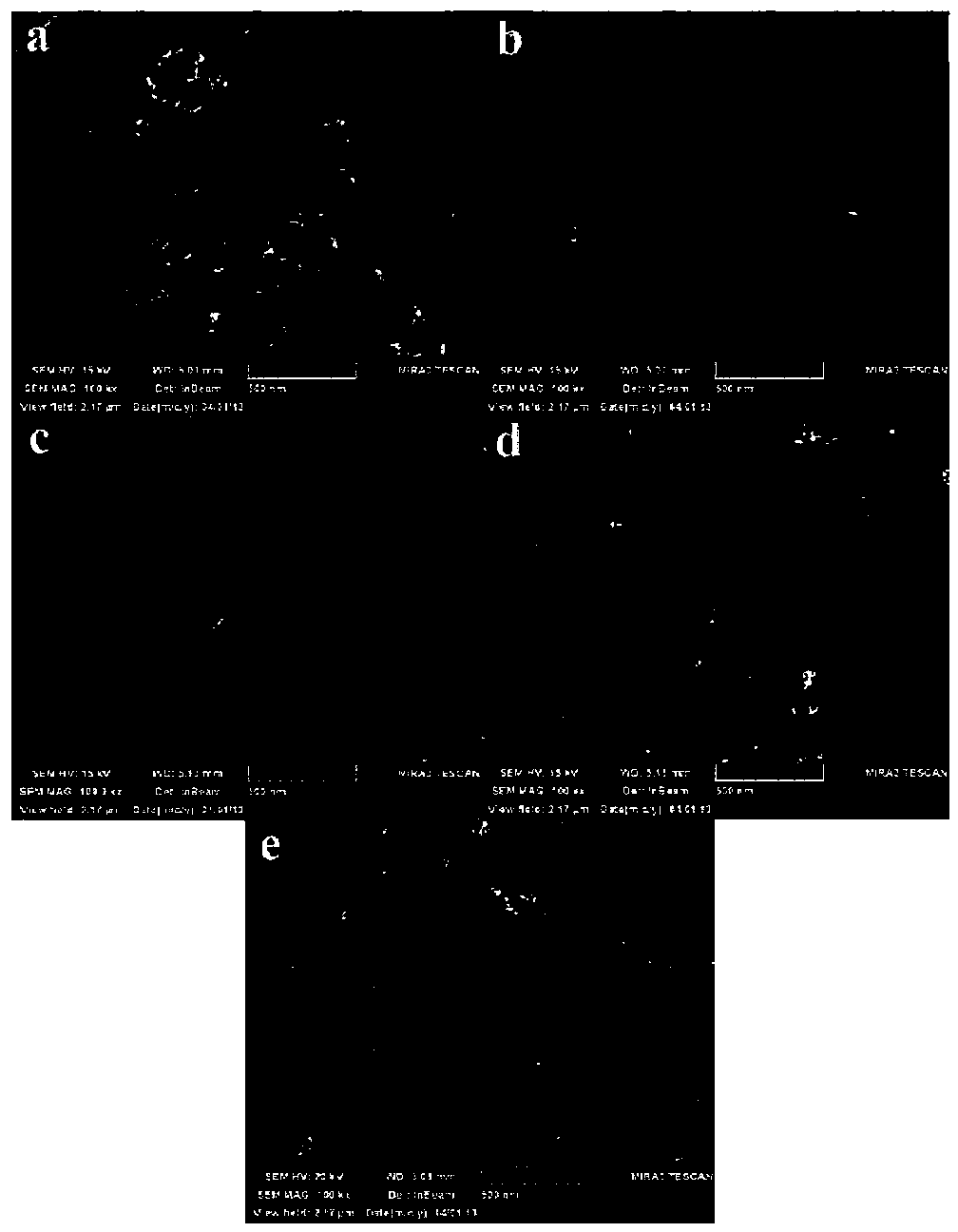

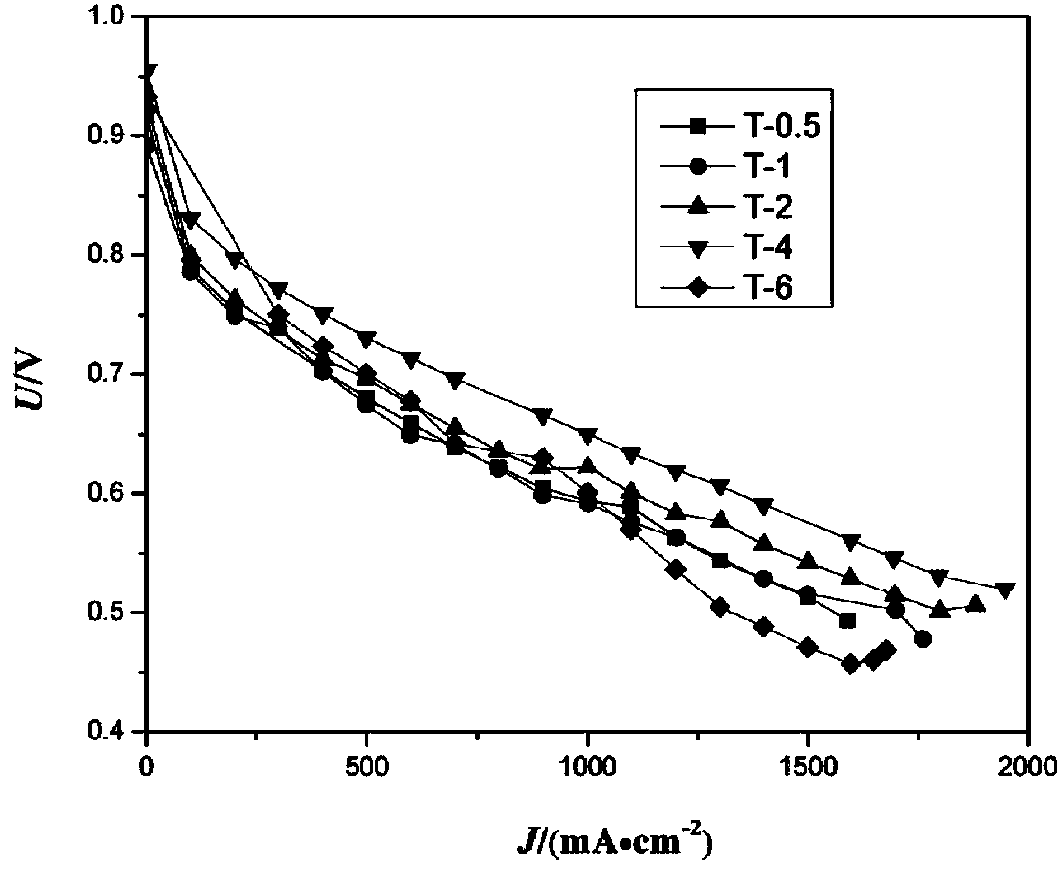

[0034] Take 1g of Pt / C catalyst (Pt mass fraction is 40%), add deionized water, isopropanol, perfluorosulfonic acid resin solution, ethylene glycol, simethicone oil 4g, 3g, 8.5g, 3g, 0.05g, the resulting mixture was dispersed at 8000rpm for 0.5h, 1h, 2h, 4h and 6h to prepare five kinds of slurries with different degrees of dispersion (these five kinds of slurries are respectively marked as T-0.5, T -1, T-2, T-4 and T-6), and finally disperse at a low speed of 3000rpm for 20min until the air bubbles in the slurry are completely removed. Take an appropriate amount of the dispersed slurry and drop it on a glass slide for 24 hours to dry for morphology analysis.figure 1 SEM images of catalyst particles at different dispersion times. It can be seen from the figure that within 4 hours, the dispersion effect of the particles improves with the increase of the dispersion time. When the dispersion time increases to 6 hours, the dispersion state of the particles does not change much.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Maximum current density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com