Composite honeycomb sandwich structure floor

A honeycomb interlayer and floor technology, which is applied to layered products, building structures, floors, etc., can solve difficult problems and achieve the effects of cost reduction, structural weight reduction, and weight reduction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

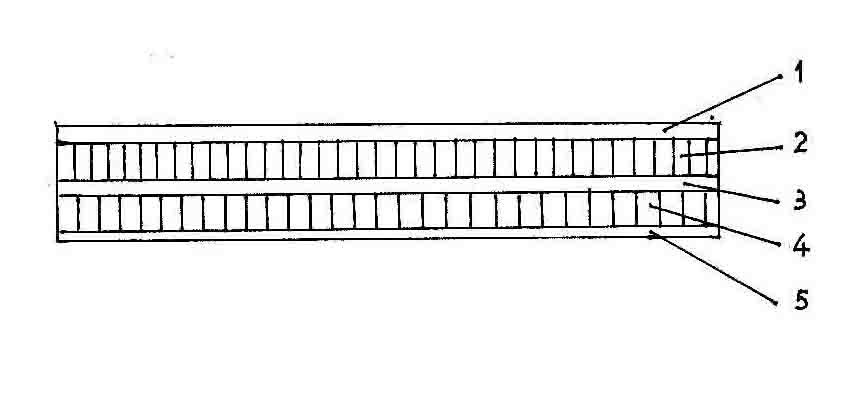

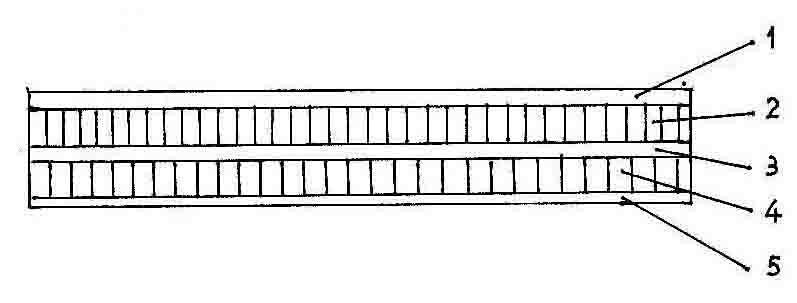

[0018] In a certain test, the single sandwich honeycomb structure panel is made of 1.2mm steel plate for the upper skin and 1.0mm steel plate for the lower skin. The material type is Q235, and its yield strength is 240Mpa. 3 , the cell side length is 5.0mm, the honeycomb core height is 25mm, and the single sandwich honeycomb panel made of compressive strength 1.3Mpa has a thickness of 27.5mm and a weight of 18.8kg per square meter. The composite honeycomb sandwich structure floor adopts 1.2mm steel plate for the upper skin, 0.5mm steel plate for the middle skin, and 0.5mm steel plate for the lower skin. The material type is Q235, and its yield strength is 240Mpa. The upper honeycomb core adopts aluminum honeycomb core material , density 100kg / m 3 , the cell side length is 1.85mm, the honeycomb core height is 5mm, the compressive strength is 5.8Mpa, the lower honeycomb core is also made of aluminum honeycomb core material, and the density is 45kg / m 3 , the cell side length is ...

Embodiment 2

[0020] In the test of making a composite honeycomb sandwich structure floor, the upper skin is made of 1.5mm steel plate, the material model is Q345, and the yield strength is 370Mpa; the middle skin and the lower skin are both made of 0.5mm steel plate, the material model is Q235, and the yield strength is 240Mpa ;The upper honeycomb core is made of aluminum honeycomb core with a density of 100kg / m 3 , the cell side length is 1.85mm, the honeycomb core height is 4mm, and the compressive strength is 5.8Mpa; the lower honeycomb core is made of aluminum honeycomb core, and the density is 470kg / m 3 , the cell side length is 5.0mm, the honeycomb core height is 25mm, and the compressive strength is 1.4Mpa; it is made into a standard floor plate of 600 mm×600 mm, and the floor is concentrated according to the national standard "SJ / T10796-2001 General Specification for Anti-static Raised Floors". Load test, floor limit concentrated load test, floor uniform load test, floor impact loa...

Embodiment 3

[0022] In the test of making a composite honeycomb sandwich structure floor, the upper skin of this example is made of 1.4mm steel plate, the material type is Q345, and the yield strength is 420Mpa; the middle skin is made of 1.0mm thick phenolic fireproof board, and the tensile strength is 120 Mpa; The skin is made of 0.6mm thick phenolic fireproof board with a tensile strength of 120 Mpa; the density of the upper aluminum honeycomb core is 110kg / m 3 , cell side length 1.875mm, honeycomb core height 5mm, compressive strength 6.2Mpa; lower aluminum honeycomb core density 47kg / m 3 , cell side length 5.0mm, honeycomb core height 25mm, compressive strength 1.4Mpa. The standard floor boards of 600 mm×600 mm are made, and according to the national standard "SJ / T10796-2001 General Specification for Anti-static Raised Floors", the floor concentrated load test, the floor limit concentrated load test, the floor uniform load test, and the floor impact load are carried out Test, floor r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com