Friction element carrier for clutch

A technology for friction elements and clutches, applied in the field of clutches, to achieve the effect of simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

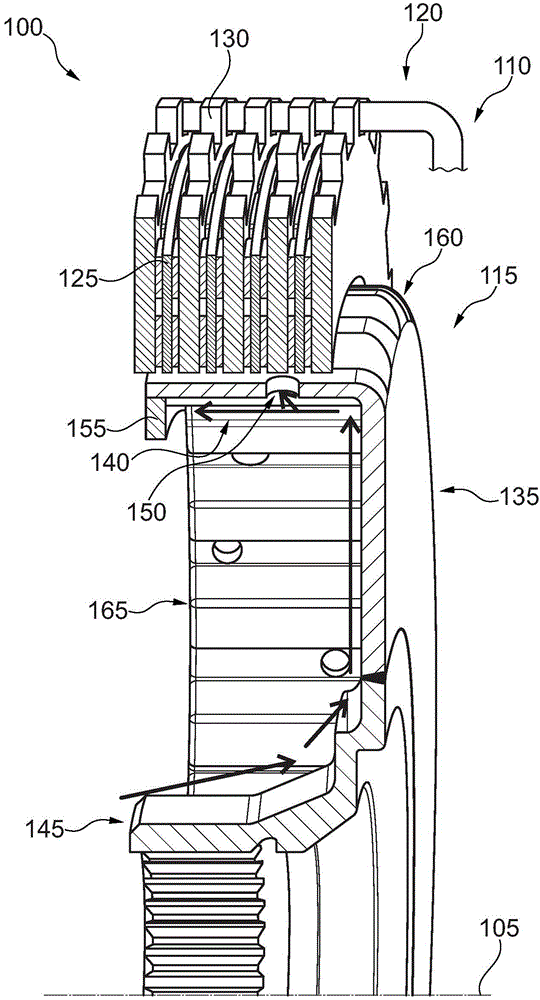

[0025] figure 1 A clutch 100 is shown for transmitting torque relative to an axis of rotation 105 . The clutch 100 is preferably designed as a wet clutch, ie it is arranged to operate in an ambient fluid 110 . Ambient fluid 110 preferably includes oil.

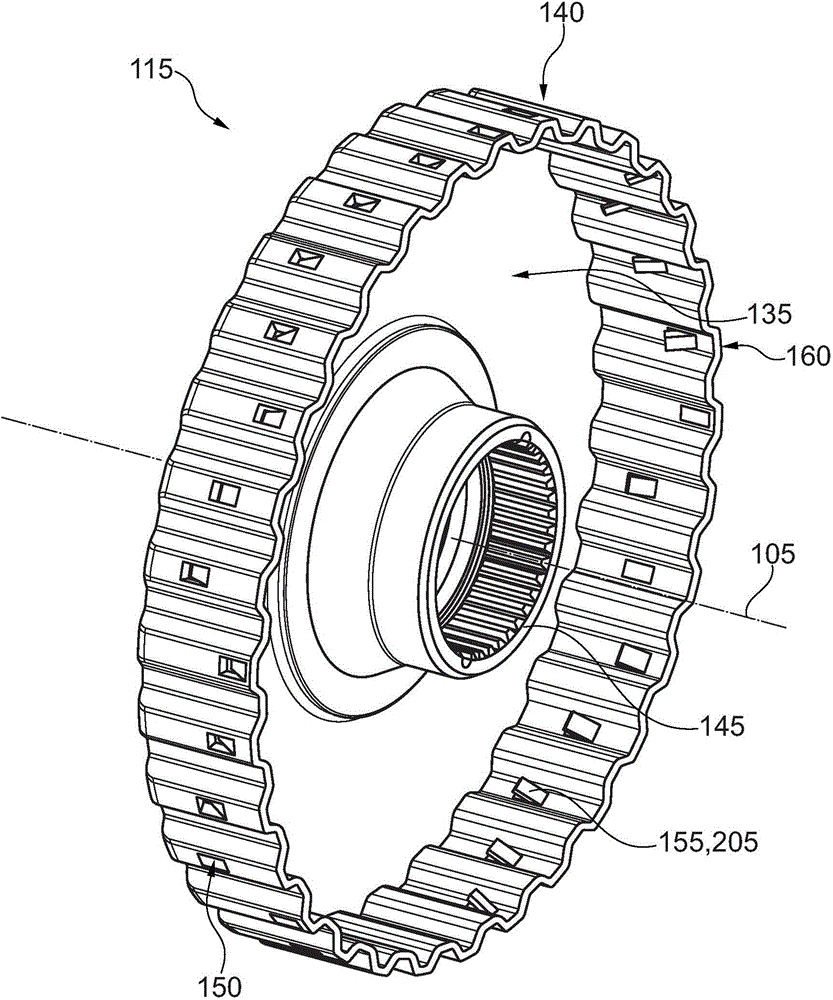

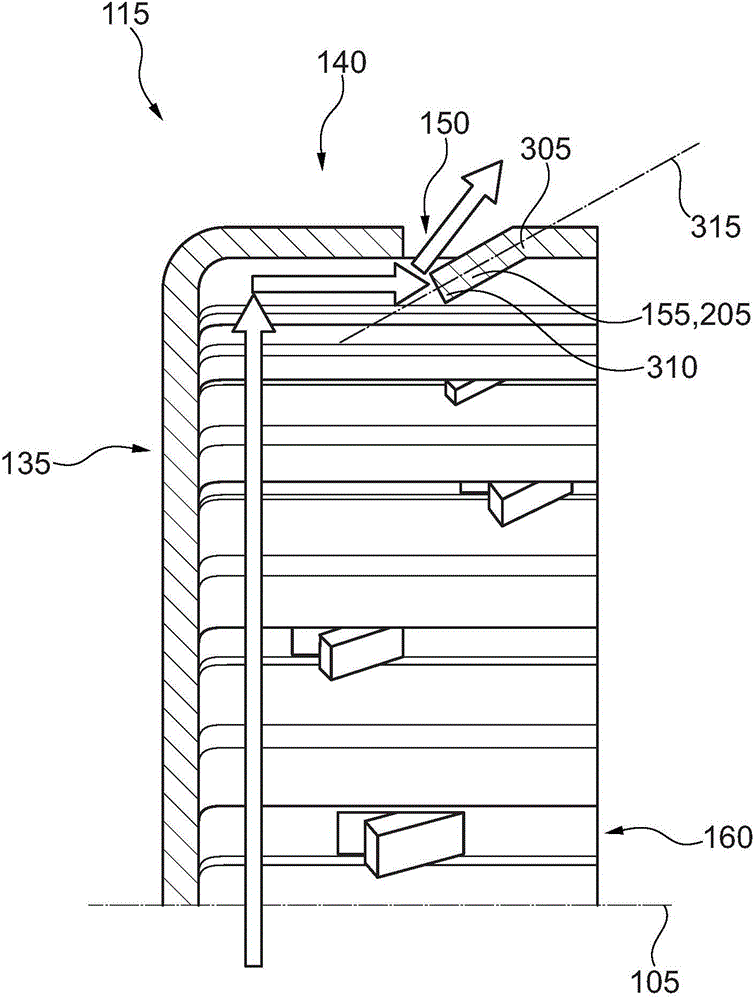

[0026] The clutch 100 includes: an inner carrier 115 , an outer carrier 120 , a first friction element 125 and a second friction element 130 . The friction elements 125 and 130 are arranged axially side by side. Preferably, a plurality of first friction elements 125 and / or a plurality of second friction elements 130 are provided, and the first friction elements and the second friction elements are arranged alternately in the axial direction. The first friction element 125 is connected by means of a toothing to the inner carrier 115 in a torque-locking manner, and the second friction element 130 is connected by means of a further toothing to the outer carrier 120 in a torque-locking manner. In the axial direction, the frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com