Acidic milk pudding and preparation method thereof

A milk pudding and acidic technology, which is applied in the field of acidic milk pudding and its preparation, can solve the problems of pudding transportation, storage and sales troubles, single variety, and products that do not reach commercial sterility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

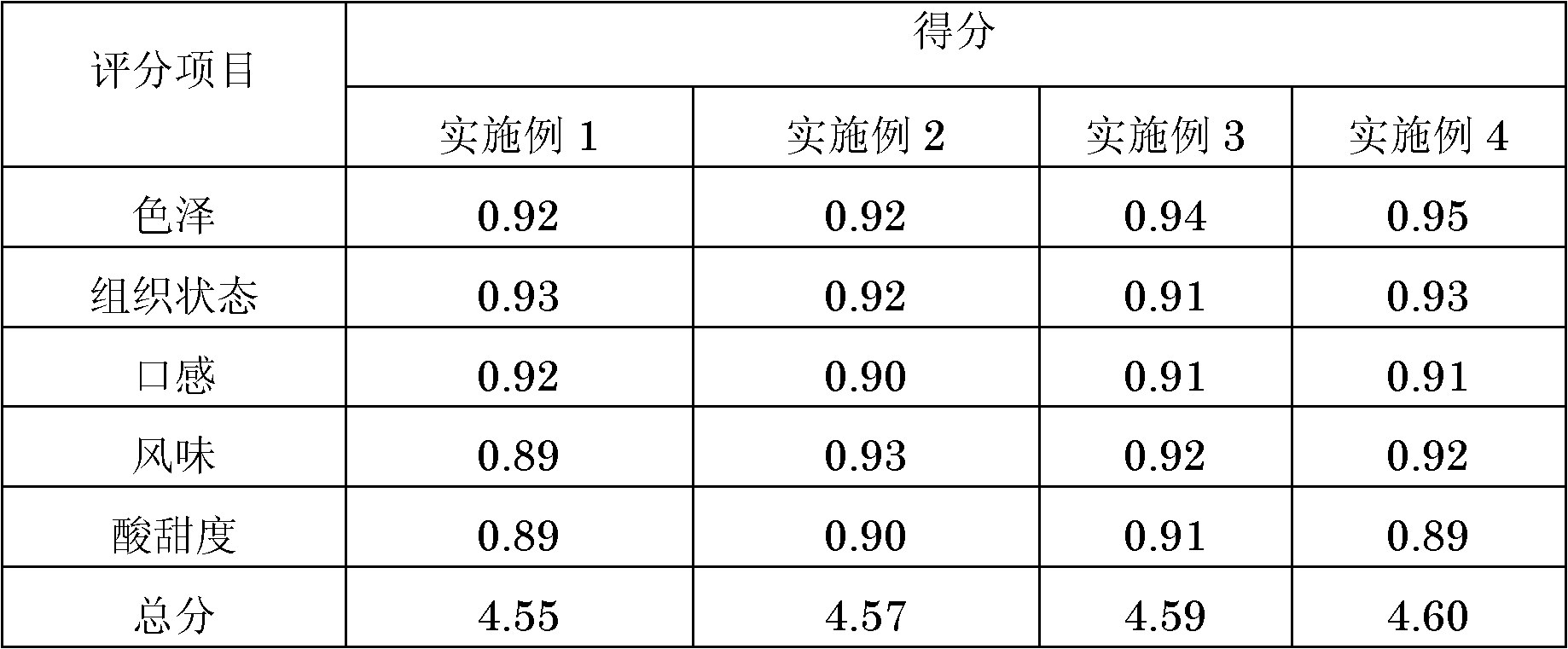

Examples

preparation example Construction

[0031] The preparation raw material of acid pudding of the present invention also includes salt substance, and this salt substance is the combination of one or several substances in sodium chloride, sodium tripolyphosphate, sodium citrate, sodium hexametaphosphate, etc., wherein It is preferably sodium chloride and sodium citrate, and the added amount of salts in the acid pudding is 0.03% to 0.08%, preferably 0.04% to 0.06%. The salt can be used as a pH buffer to buffer the pH system of the acidic pudding, giving the acidic pudding a softer flavor.

[0032] An acidity regulator is added to the acid pudding provided by the invention, and the acidity regulator is one or a combination of lactic acid, citric acid, malic acid, tartaric acid and the like. The appropriate amount of acidity regulator in the present invention is the amount of the acidity regulator used to adjust the acidity of the final product to pH4.2-pH4.4, preferably pH4.3-pH4.35.

[0033] In the present invention...

Embodiment 1

[0047] 1. Raw material formula (measured in 1000g):

[0048] White sugar: 70g; anhydrous butter: 20g; stabilizer: (sodium carboxymethylcellulose 1g+carrageenan 0.5g+konjac gum 0.2g+agar 0.3g+diacetyl tartrate monoglyceride 1g) 3g; appropriate amount of lactic acid; the balance is milk .

[0049] 2. Production method:

[0050] 1. Mix the fresh milk, white sugar, anhydrous butter and stabilizer in the raw material formula evenly at 60°C for 35 minutes, including 857g of fresh milk;

[0051] 2. Cool the mixed material to 45°C, adjust the acidity with lactic acid to pH 4.2, and then add fresh milk to 1000g;

[0052] 3. Homogenize the mixed material at 60°C and 17MP pressure;

[0053] 4. Sterilize the homogenized mixed material at 95°C for 300 seconds;

[0054] 5. Cool down the sterilized mixed material to 80°C, put it into the insulation tank to be loaded, and keep stirring all the time.

[0055] 6. Under the condition of maintaining the temperature of the mixed material > 65...

Embodiment 2

[0057] 1. Raw material formula (measured in 1000g):

[0058] White sugar: 80g; anhydrous butter: 16g; stabilizer: (sodium carboxymethylcellulose 1g+carrageenan 0.4g+agar 0.3g+starch 1g+sucrose fatty acid ester 1g+sodium chloride 0.3g) 4g; appropriate amount of citric acid; raw mango Syrup 8g; the rest is milk.

[0059] 2. Production method:

[0060] 1. Mix the fresh milk, white sugar, anhydrous butter and stabilizer in the raw material formula evenly at 65°C for 30 minutes, including 850g of fresh milk;

[0061] 2. Add mango puree and stir;

[0062] 3. Cool the mixed material to 48°C, adjust the acidity with citric acid to pH 4.3, and then add fresh milk to 1000g;

[0063] 4. Homogenize the mixed material at 65°C and 18MP pressure;

[0064] 5. Sterilize the homogenized mixed material at 110°C for 10 minutes;

[0065] 6. Cool down the sterilized mixed material to 80°C, put it into the insulation tank to be loaded, and keep stirring.

[0066] 7. Under the condition of main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com