Seed coating agent special for direct seeding rice

A special, oxygen-enhancing agent technology, applied in the field of preparations for crop seed treatment, to achieve the effects of promoting multiple emergence, preventing rotten seeds, and preventing physiological withering and dead seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Accurately weigh 60 kg of superabsorbent resin, 20 kg of magnesium peroxide, 1 kg of carbofuran, 10 kg of carbendazim, 2 kg of prochloraz, 5 kg of sodium sulfonate, 10 kg of cartap, 0.1 kg of naphthaleneacetic acid, 0.5 kg of uniconazole, 10 kg of zinc sulfate, 10 kg of ferrous sulfate, 10 kg of borax, 10 kg of magnesium sulfate, 10 kg of molybdenum sulfate, 10 kg of copper sulfate and 831.4 kg of attapulgite, the above materials are produced according to the production process, That is, the special seed coating agent for direct-seeding rice is obtained.

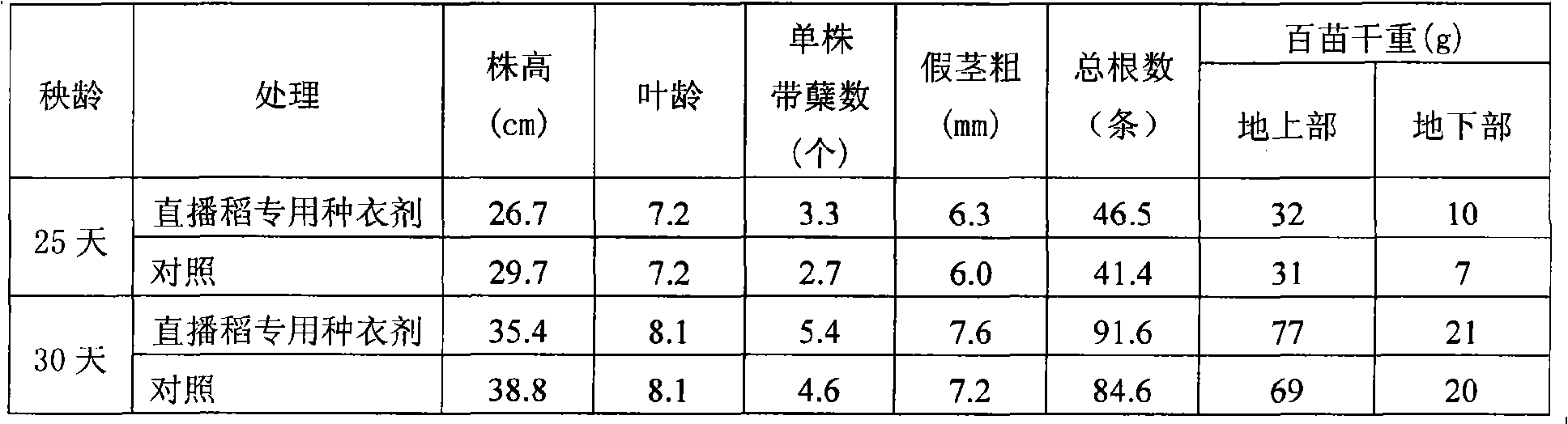

[0031] In 2006 and 2007, the rice dry-seeding application test of special seed coating agent for direct-seeding rice was carried out in Erqiao Village, Wantou Town, Guangling District, Yangzhou City, Jiangsu Province. The tested variety is Yangfujing No. 8, with no seed dressing as the control, sown on June 15, every 666.7m 2 The seeding rate is 4 kg, and the area of the plot is 66.7m 2 , repeat 3 times. After so...

Embodiment 2

[0042] Accurately weigh 40 kg of superabsorbent resin, 30 kg of calcium peroxide, 1.2 kg of carbosulfan, 7 kg of carbendazim, 3 kg of metalaxyl, 2 kg of prochloraz, 5 kg of sulfonate, and 20 kg of imidacloprid , 0.04 kg of indolebutyric acid, 0.9 kg of paclobutrazol, 5 kg of zinc oxide, 15 kg of ferrous sulfate, 10 kg of borax, 10 kg of magnesium sulfate, 10 kg of molybdenum sulfate, 10 kg of copper sulfate and 830.86 kg of attapulgite. The material is produced according to the production process, and the special seed coating agent for direct-seeding rice is obtained.

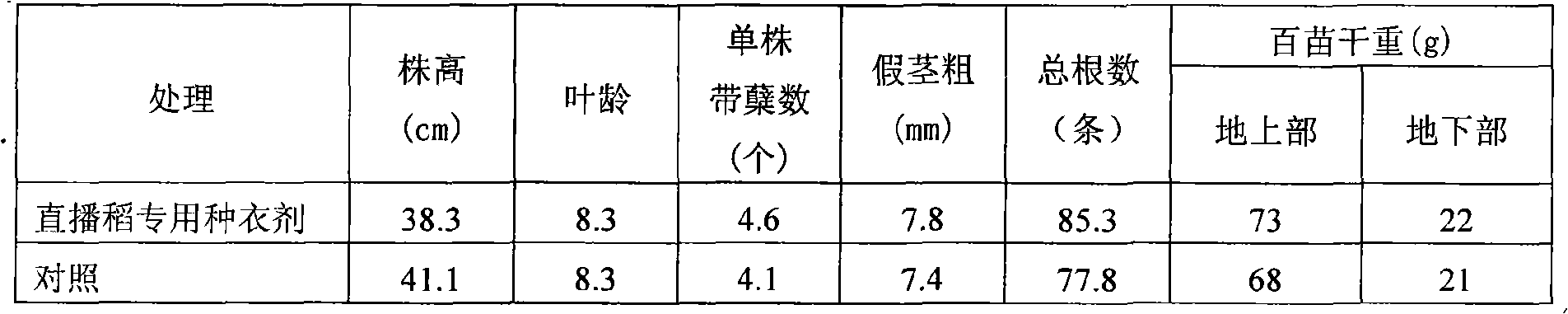

[0043] In 2007, in Baoying County, Yangzhou City, Jiangsu Province, a special seed coating agent for direct-seeding rice was tested for direct-seeding rice water application. The tested variety is Huaidao No. 9, with no seed dressing as the control, sown on June 22, every 666.7m 2 The seeding rate is 6 kg, and the area of the plot is 333.4m 2 , repeat 2 times. After sowing, investigate the emergence rate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com