Simulation system and method capable of reproducing soot evolution characteristics under post-injection strategy of engine

An engine and soot technology, applied in the field of simulation system that can reproduce the evolution characteristics of soot under the engine post-injection strategy, can solve the problems of complex engine combustion conditions and the inability to study the influence of a single variable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

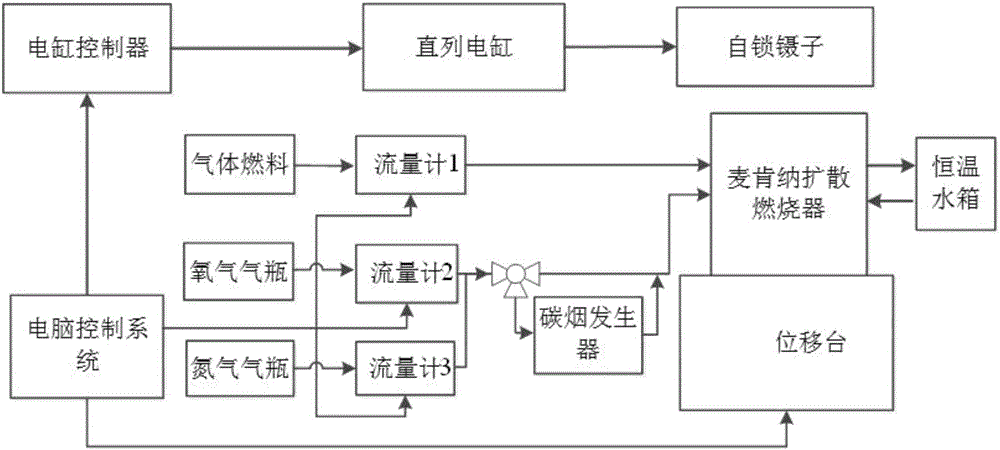

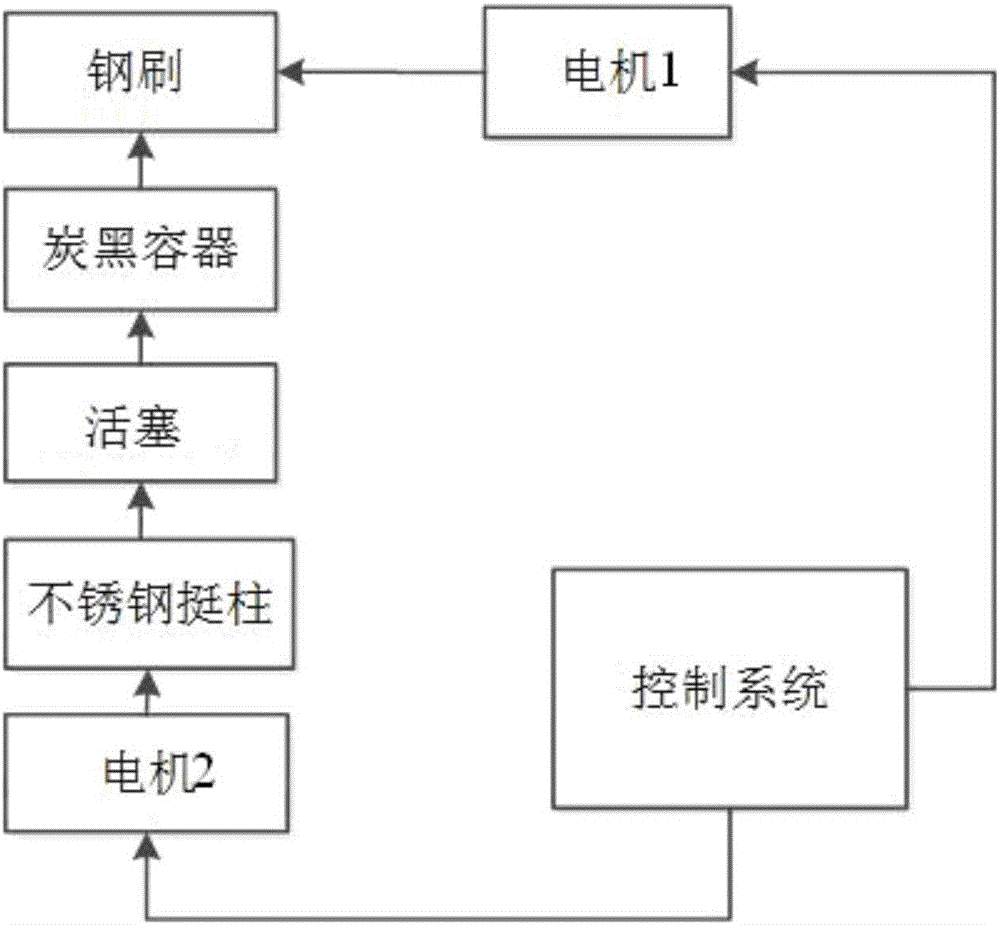

[0026] Such as figure 1 As shown, the present invention proposes a simulation system that can reproduce the soot evolution characteristics under the engine post-injection strategy, including McKenna diffusion burner, displacement stage, constant temperature water tank, soot generator, in-line electric cylinder, electric cylinder control device, self-locking tweezers and computer control system.

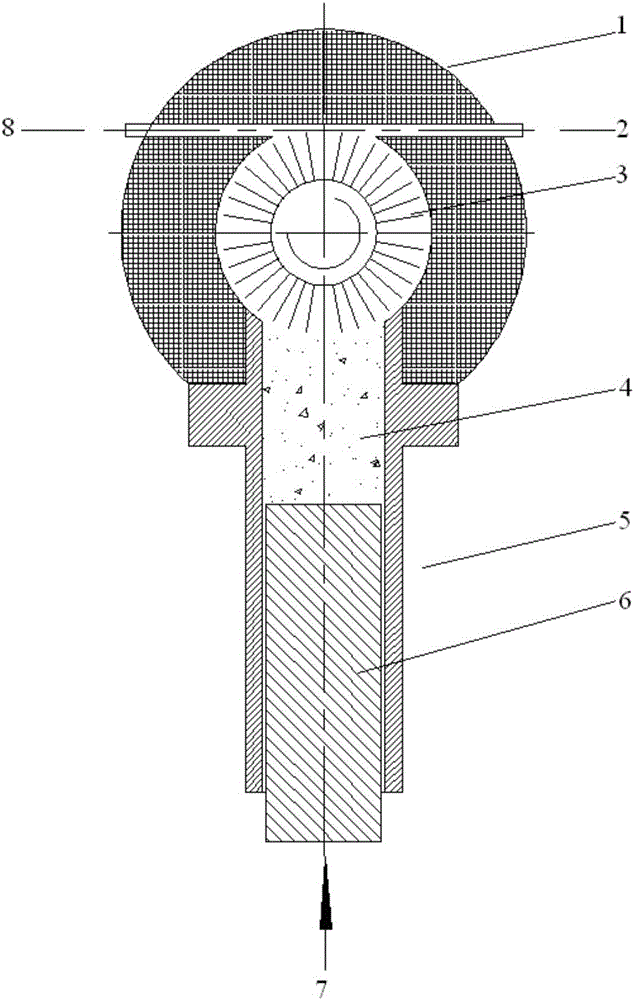

[0027] The McKenna diffusion burner includes a cylindrical body, a coil is arranged inside the cylindrical body, a central steel pipe is arranged at the coaxial position of the cylindrical main body, and metal sintered steel pipes are arranged around the central steel pipe. A met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com