Combustion system capable of simulating impact on soot discharge from post injection strategy, and control method

A combustion system and soot technology, which is applied in the direction of internal combustion engine testing, engine testing, machine/structural component testing, etc., can solve the problems of large changes in the combustion cycle, complex combustion conditions, and capital consumption, so as to avoid waste of resources, The effect of saving test cost and test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining and illustrating the present invention, and are not intended to limit the present invention.

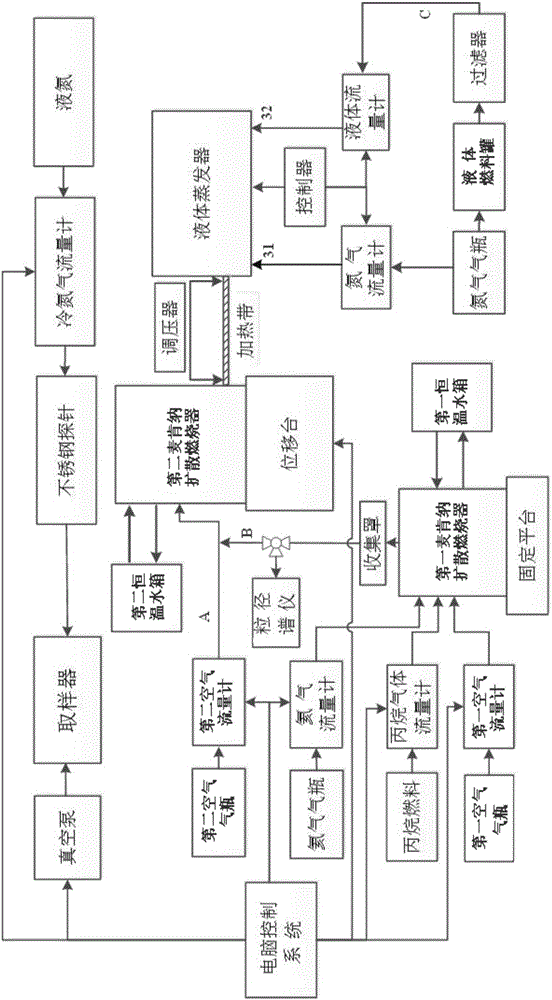

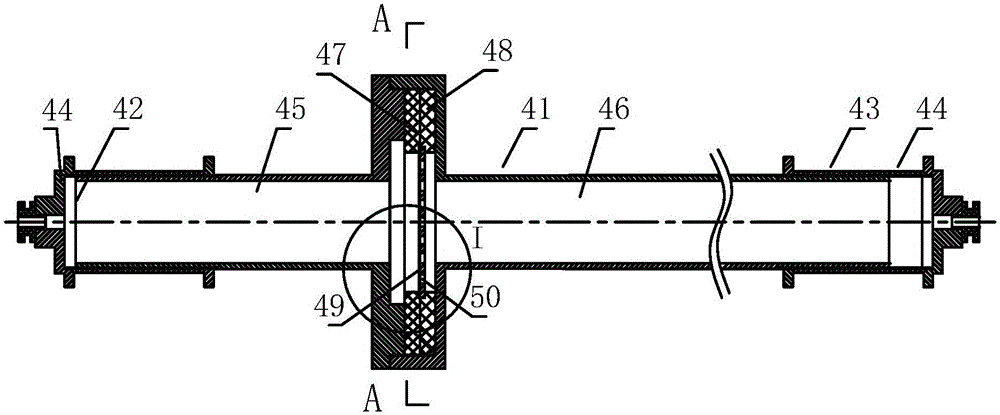

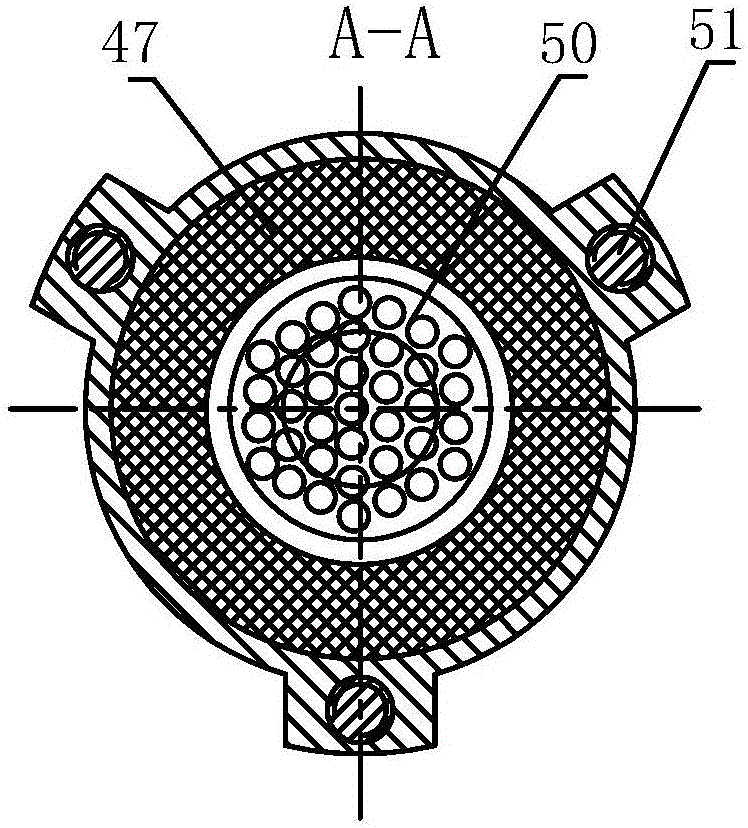

[0030] Such as figure 1As shown, the present invention is a combustion system capable of simulating the influence of the post-injection strategy on soot emission, including a displacement platform, a fixed platform, a first McKenna diffusion burner, a second McKenna diffusion burner, and a particle size spectrometer , a first constant temperature water tank, a second constant temperature water tank, a vacuum pump, a sampler, a stainless steel probe, a liquid fuel evaporator, a controller and a computer control system; the first McKenna diffusion burner is arranged on the fixed platform, The second McKenna diffusion burner is arranged on the displacement pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com