Dry method selective solid material separation device

A solid material and separation device technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve problems such as increased energy consumption of equipment, restrictions on the development of electric separation, immature processes, etc. Achieve low cost, good environmental protection effect, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

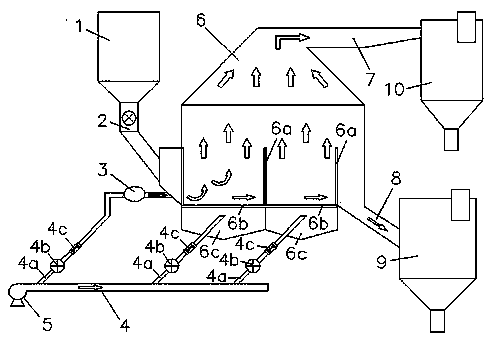

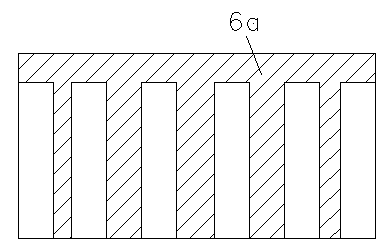

[0016] figure 1 A working system diagram of a dry selective solid material separation device is shown. In the figure, the dry selective solid material separation device includes a solid mixture material storage bin 1, a feeder 2, a fluidized separation bed 6, a blower 5, an air conveying main pipe 4, an air connection box 3, a high-density material storage bin 9 and The low-density material storage bin 10, the solid mixture material storage bin 1 is connected to the fluidized separation bed 6 through the feeder 2, the bottom outlet of the fluidized separation bed 6 is connected to the high-density material storage bin 9 through the conveying pipeline 8, and the top outlet passes through the upper air outlet. The channel 7 is connected to the low-density material storage bin 10 . The air conveying main pipe 4 connected with the blower 5 is provided with an air conveying branch pipe 4a, a flow control valve 4b and a flow meter 4c are installed on the air conveying branch pipe 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com