Preparation method of inorganic heat preservation paste

An inorganic thermal insulation and paste technology, which is applied in the field of thermal insulation paste preparation, can solve the problems of less research, poor physical properties, and thermal insulation paste with no performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

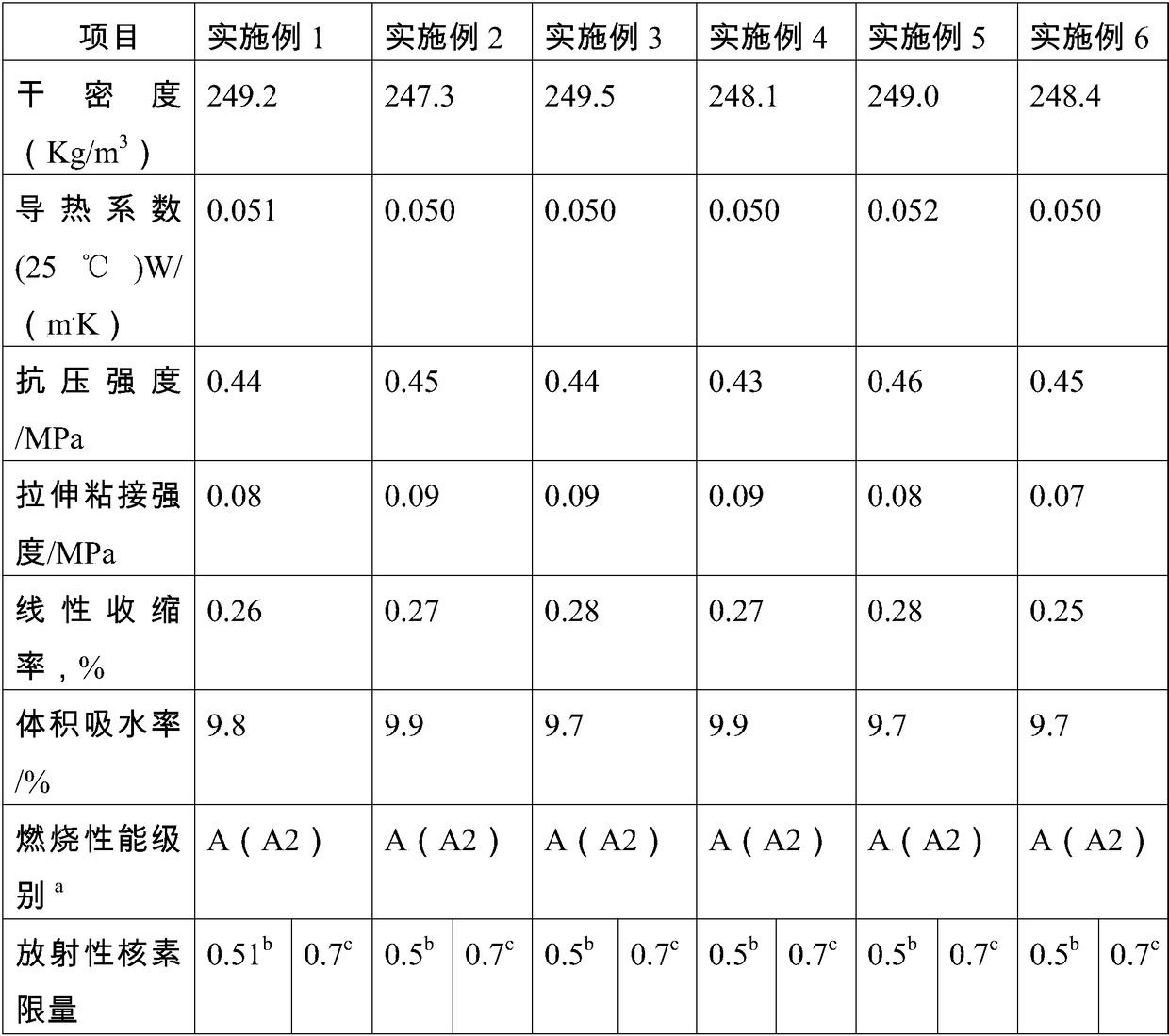

Examples

Embodiment 1

[0025] A preparation method of inorganic thermal insulation paste, comprising the following steps:

[0026] S1. Put 17Kg polypropylene fiber filaments in a water tank to disperse and add them to the tank. After adding an appropriate amount of water to the tank, put the tank under the mixer and stir, and control the paddle head of the stirring paddle to be close to the bottom of the tank. , during the stirring process, add 4Kg additives, 38Kg modified additives, 30Kg mica powder in turn, and continue stirring after adding an appropriate amount of water;

[0027] S2. Add 70Kg of vitrified microbeads, stir for 4 minutes, and increase the height of the paddle by 550mm; put 70Kg of floating beads, 30Kg of high beads, and 20Kg of horn powder into the tank in turn, add an appropriate amount of water, and stir until the dry lumps disappear;

[0028] S3. Lower the paddle head of the stirring paddle to close to the bottom of the pulling tank, shovel the residual material inside the pull...

Embodiment 2

[0031] A preparation method of inorganic thermal insulation paste, comprising the following steps:

[0032] S1. Put 10Kg polypropylene fiber filaments in a water tank to disperse and add them to the tank. After adding an appropriate amount of water into the tank, put the tank under the mixer and stir, and control the paddle head of the stirring paddle to be close to the bottom of the tank. , during the stirring process, add 3Kg additives, 20Kg modified additives, 40Kg mica powder in turn, and continue stirring after adding an appropriate amount of water;

[0033] S2. Add 80Kg of vitrified microbeads to the pulling tank, stir for 5 minutes, and raise the height of the paddle by 500mm; put 50Kg of floating beads, 20Kg of high beads, and 30Kg of horn powder into the pulling tank in turn, add an appropriate amount of water, and stir until the dry lumps disappear ;

[0034] S3. Lower the paddle head of the stirring paddle to close to the bottom of the pulling tank, shovel the resi...

Embodiment 3

[0037] A preparation method of inorganic thermal insulation paste, comprising the following steps:

[0038] S1. Put 20Kg polypropylene fiber filaments in a water tank to disperse and add them to the tank. After adding an appropriate amount of water into the tank, put the tank under the mixer and stir, and control the paddle head of the stirring paddle to be close to the bottom of the tank. , during the stirring process, add 5Kg additives, 45Kg modified additives, 20Kg mica powder in turn, and continue stirring after adding an appropriate amount of water;

[0039] S2. Add 50Kg of vitrified microbeads to the vat, stir for 3 minutes, and increase the height of the paddle by 600mm; put 80Kg of floating beads, 40Kg of high beads, and 10Kg of horn powder into the vat in turn, add an appropriate amount of water, and stir until the dry lumps disappear. ;

[0040] S3. Lower the paddle head of the stirring paddle to close to the bottom of the pulling tank, shovel out the residual mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com