Preparation method of boiling-resistant type chicken powder with natural fresh shrimp flavor

A technology of fresh shrimp and chicken powder, which is applied in the field of seasoning processing, can solve the problems of flavor loss and other problems, and achieve the effects of improving cooking resistance, high extraction rate and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

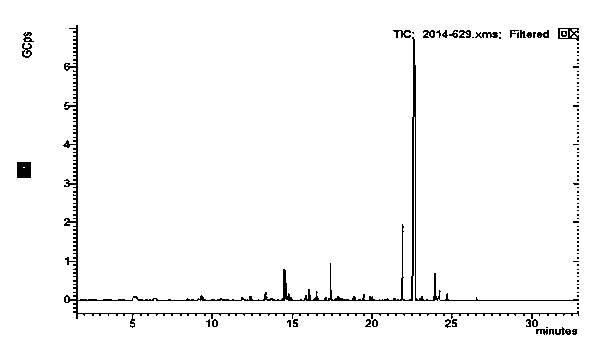

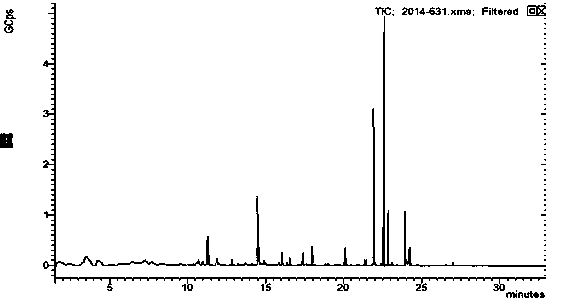

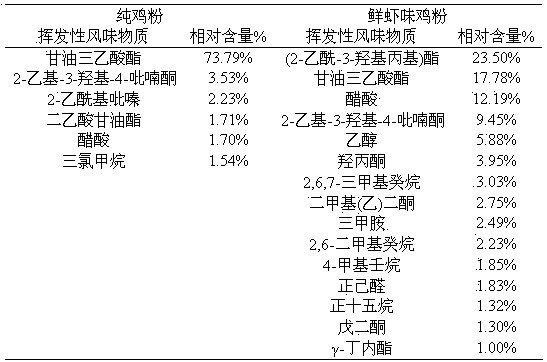

Image

Examples

Embodiment 1

[0036] Example 1: Boiling-resistant chicken powder with natural fresh shrimp flavor (extra strong flavor)

[0037] (1) Beating: According to the fresh shrimp:water mass ratio of 1:1, the fresh shrimp is beaten.

[0038] (2) For fresh shrimp, add 0.5% enzyme (calculated as shrimp), enzymolysis temperature is 55°C, compound protease:flavor protease mass ratio is 2:1, pH is 6.5, and enzymolysis reaction time is 4 hours.

[0039] (3) Treat the enzymolyzed shrimp hydrolyzate in a boiling water bath at 100°C for 20 min.

[0040] (4) Filter and remove the slag from the enzyme-inactivated shrimp enzymatic solution, centrifuge (3500 r / min, 10 min) to remove floating debris, and take an appropriate amount of clear liquid.

[0041] (5) Then add 2% reducing sugar and 1.5% amino acid in shrimp enzymatic hydrolyzate, the reaction time is 90 min; the pH value of the reaction system is 7.0; the reaction temperature is 100°C.

[0042] (6) Concentrate the product after thermal reaction in vac...

Embodiment 2

[0045] Example 2: Boiling-resistant chicken powder with natural fresh shrimp flavor (conventional flavor)

[0046] (1) Beating: According to the fresh shrimp:water mass ratio of 1:1, the fresh shrimp is beaten.

[0047] (2) For fresh shrimp, add 0.5% enzyme (calculated as shrimp), enzymolysis temperature is 55°C, compound protease:flavor protease mass ratio is 2:1, pH is 6.5, and enzymolysis time is 4 hours. Soybean protein powder is dissolved in water at a ratio of 8g / 100mL, compound protease 0.4% (calculated as soybean protein), pH 6.0, reaction temperature 55°C, enzymolysis reaction time 6 h.

[0048] (3) The enzymolyzed shrimp hydrolyzate and soybean protein hydrolyzate were treated in a boiling water bath at 100°C for 20 min, respectively.

[0049] (4) Filter the soybean protein enzymatic hydrolyzate and shrimp enzymatic hydrolyzate after deactivation to remove slag, centrifuge (3500 r / min, 10 min) to remove floating sundries, and take an appropriate amount of supernatan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com