Edible fungus clear soup hotpot base material and production method thereof

A production method and a technology of hot pot bottom material, which are applied in the field of food condiments, can solve the problems of not strong fragrance and indistinct flavor characteristics of edible mushrooms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

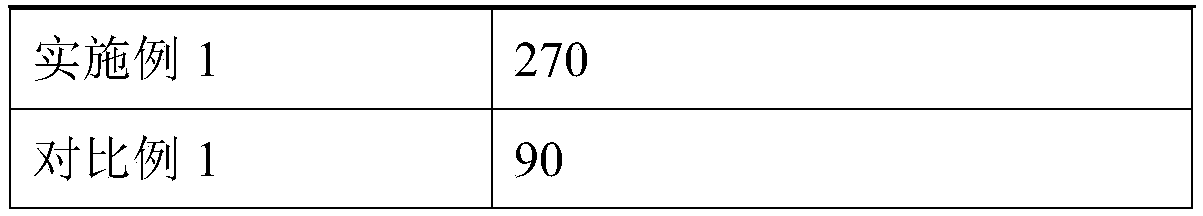

Examples

Embodiment 1

[0028] First, prepare the edible fungus fresh-flavor extract, using the following steps: A. First-level refinement and compounding: select dried shiitake mushrooms, dried tea tree mushrooms, dried boletus edulis, dried morels, dried pine mushrooms, and dried poplars Mushrooms and dried enoki mushrooms were pulverized into powder, according to 13 parts of dried shiitake mushrooms, 15 parts of dried tea tree mushrooms, 6 parts of dried boletus edulis, 8 parts of dried morels, 2 parts of dried pine mushrooms, 4 parts of dried poplar mushrooms , 3 parts of dried enoki mushrooms, mix the powder evenly to obtain a compound edible fungus powder; B. Acid softening: take 100 parts of water, add 8 parts of salt, 0.5 parts of hydrochloric acid, 1.2 parts of citric acid to prepare an acid solution containing salt , Add 8 parts of the compound edible fungus powder obtained in step A, soak in acid to soften at room temperature for 5 hours, and keep stirring during acid softening; C. Cooking: ...

Embodiment 2

[0038] First, prepare the edible fungus fresh-flavor extract, using the following steps: A. First-level refinement and compounding: select dried shiitake mushrooms, dried tea tree mushrooms, dried boletus edulis, dried morels, dried pine mushrooms, and dried poplars Mushrooms and dried Enoki mushrooms were crushed into powders, according to 14 parts of dried shiitake mushrooms, 14 parts of dried tea tree mushrooms, 7 parts of dried boletus edulis, 7 parts of dried morels, 3 parts of dried pine mushrooms, 3 parts of dried poplar mushrooms , 4 parts of dried enoki mushrooms, mix the powder evenly to obtain a compound edible fungus powder; B. Acid softening: take 100 parts of water, add 9 parts of salt, 0.5 parts of hydrochloric acid, and 1.3 parts of citric acid to prepare a salt-containing acid solution , Add 9 parts of the compound edible fungus powder obtained in step A, soak in acid to soften at room temperature for 6 hours, keep stirring during acid softening; C. Cooking: Aft...

Embodiment 3

[0047] First, prepare the edible fungus fresh-flavor extract, using the following steps: A. First-level refinement and compounding: select dried shiitake mushrooms, dried tea tree mushrooms, dried boletus edulis, dried morels, dried pine mushrooms, and dried poplars Mushrooms and dried enoki mushrooms were pulverized into powder separately, according to 15 parts of dried shiitake mushrooms, 13 parts of dried tea tree mushrooms, 8 parts of dried boletus edulis, 6 parts of dried morels, 4 parts of dried pine mushrooms, and 2 parts of dried poplar mushrooms. , 5 parts of dried enoki mushrooms, mix the powder evenly to obtain a compound edible fungus powder; B. Acid softening: take 100 parts of water, add 10 parts of salt, 0.5 part of hydrochloric acid, and 1.4 parts of citric acid to prepare a salt-containing acid solution , Add 10 parts of the compound edible fungus powder obtained in step A, soak in acid to soften at room temperature for 7 hours, and keep stirring during acid sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com