Method for preparing high-stability tobacco natural flavor extract

A technology with natural flavor and high stability, applied in tobacco, tobacco preparation, fat production, etc., can solve the problems of volatilization loss of volatile flavor components, loss of volatile flavor components, etc., and achieve improved smoking quality, convenient operation, and aroma natural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

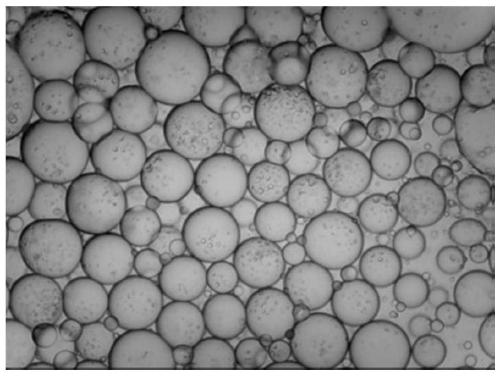

Image

Examples

preparation example Construction

[0029] The application provides a method for preparing a highly stable tobacco natural flavor extract, comprising the following steps:

[0030] (1) Pulverize the tobacco, pass through a 40-400 mesh sieve, add water 3-20 times the weight of the tobacco leaves, mix and stir evenly, and ultrasonically treat for 0.5-2 hours to obtain a suspension A; in this application, the tobacco includes One or more combinations of tobacco leaves, tobacco leaf powder, recycled shredded tobacco or tobacco leaf leftovers can all realize the technical solutions of the present application.

[0031] (2) Distill the suspension A in a steam distillation device at 100-180°C for 2-6 hours, separate the collected liquid to obtain tobacco essential oil, and at the same time pour the separated water phase back into the suspension A to obtain the suspension B;

[0032] (3) Centrifuge or filter the suspension B (70-100 mesh) to obtain the tobacco extract C, add the filter residue to water 5-10 times the weig...

Embodiment 1

[0038] (1) Weigh 100 g of tobacco leaf waste, crush it with a mechanical pulverizer, pass through a 40-mesh sieve, add water 8 times the weight of the tobacco leaf raw material, stir evenly, and conduct ultrasonic treatment at 160w for 30 minutes at room temperature. Add the suspension of tobacco dust after ultrasonic treatment into the steam distillation device (connect the steam generator and the condensation device), feed water steam at 130°C for distillation for 3 hours, and separate the tobacco essential oil from the oil phase in the condensate, and the separated The aqueous phase is poured back into the tobacco dust suspension.

[0039] (2) Filter the distilled tobacco powder suspension with 60 mesh and 100 mesh filter screens respectively to obtain tobacco extract and filter residue, add 6 times the weight of water to the filter residue again, stir and extract at 80°C for 30 minutes and then Perform 60-mesh and 100-mesh filter screen filtration, combine the two tobacco ...

Embodiment 2

[0042] (1) Weigh 100g of tobacco leaf leftovers, use a mechanical pulverizer to crush it, pass through a 60-mesh sieve, add water 12 times the weight of the tobacco leaf raw material, and NaCl of 2% of the tobacco leaf weight. After stirring evenly, 180w ultrasonic treatment at 50°C 30 minutes. Add the soot powder suspension after ultrasonic treatment into the steam distillation device, keep the solution in a slightly boiling state for distillation by electric heating for 4 hours, collect the condensed mixed liquid, and add 1 / 2 and 1 / 3 volumes of The n-hexane is extracted twice, the two extracts are combined, the tobacco essential oil is separated by vacuum concentration, and the condensed water phase after extraction is combined into the tobacco powder suspension.

[0043] (2) Centrifuge the distilled tobacco powder suspension at 4000rpm to obtain tobacco extract and filter residue, add 6 times the weight of water to the filter residue again, stir and extract at 80°C for 30 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com