Dandelion coarse grain biscuit and preparation method thereof

A technology of dandelion and dandelion powder is applied in the directions of dough preparation, pre-baked dough processing, baking, etc., to achieve the effects of simplifying the processing process, high residual rate, and shortening the production and processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

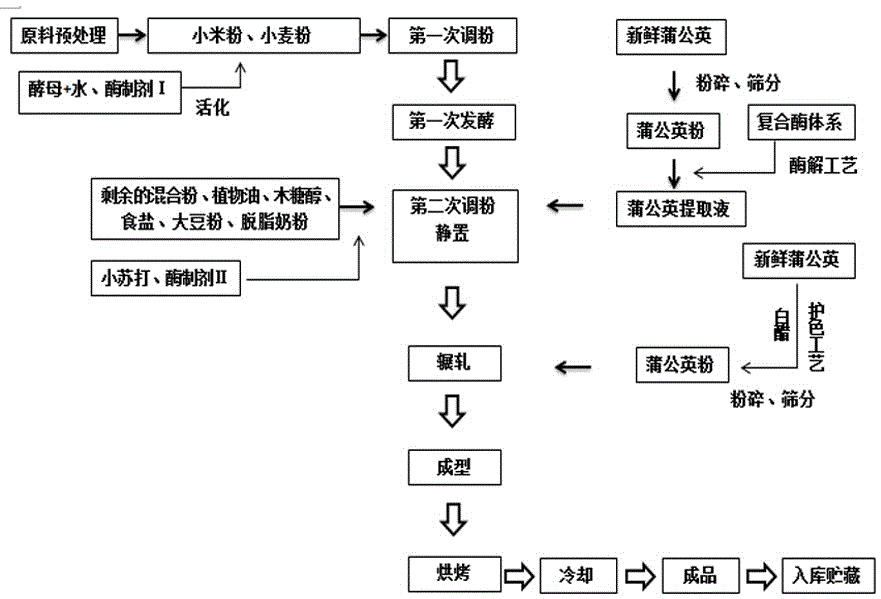

[0041] The preparation method of described dandelion multigrain biscuit, its process step is:

[0042] (1) Raw material pretreatment

[0043] Select fresh dandelions in the vigorous growth period to remove roots, soil and impurities, etc., wash them with clean water, add appropriate amount of white vinegar to the water, adjust the pH value to 6.5, heat to 75-80°C, and put fresh dandelions in water to blanch for 1-2 Minutes, then washed with water, removed and drained, then dried, crushed, sieved through an 80-mesh sieve, and reserved for use; millet was ground into powder and passed through an 80-mesh sieve, and soybeans and white sesame were passed through a 120-mesh sieve for later use.

[0044] (2) Preparation of dandelion extract

[0045] Select fresh dandelions in the vigorous growth period to remove roots, soil and impurities, and drain; then dry, crush, and sieve through a 100-mesh sieve; take appropriate amount of dandelion powder, add water, keep the ratio of materia...

Embodiment 1

[0058] A kind of dandelion coarse grain biscuit described in the present embodiment, the component during batching and the mass parts of each component are:

[0059] 2.5 parts of dandelion powder, 30 parts of millet flour, 8 parts of vegetable oil, 18 parts of xylitol, 1.8 parts of yeast, 10 parts of eggs, 0.6 parts of salt, 0.8 parts of soybean flour, 50 parts of wheat flour, 1.6 parts of baking soda, 30 parts of water, 3.0 parts of dandelion extract, 0.5 parts of sesame powder, 2.0 parts of skimmed milk powder, 0.02 parts of enzyme preparation Ⅰ, 0.03 parts of enzyme preparation Ⅱ, and the amount of compound enzyme solution added was 50 μL / 100m parts of dandelion.

[0060] The process steps are as follows:

[0061] (1) Raw material pretreatment

[0062] Select fresh dandelions in the vigorous growth period to remove roots, soil and impurities, etc., wash them with clean water, add appropriate amount of white vinegar to the water, adjust the pH value to 6.5, heat to 75-80°C,...

Embodiment 2

[0077] A kind of dandelion coarse grain biscuit described in the present embodiment, the component during batching and the mass parts of each component are:

[0078] 3.0 parts of dandelion powder, 25 parts of millet flour, 7 parts of vegetable oil, 17 parts of xylitol, 2.0 parts of yeast, 10 parts of eggs, 0.5 parts of salt, 1.0 parts of soybean flour, 55 parts of wheat flour, 1.4 parts of baking soda, 32 parts of water , 2.5 parts of dandelion extract, 0.6 part of sesame powder, 2.0 parts of skimmed milk powder, 0.03 part of enzyme preparation Ⅰ, 0.02 part of enzyme preparation Ⅱ, and the amount of compound enzyme solution added was 50 μL / 100m parts of dandelion.

[0079] The process steps are as follows:

[0080] (1) Raw material pretreatment

[0081] Select fresh dandelions in the vigorous growth period to remove roots, soil and impurities, etc., wash them with clean water, add appropriate amount of white vinegar to the water, adjust the pH value to 6.5, heat to 75-80°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com