Protection and moist tobacco sheet and manufacture method thereof

A tobacco sheet, sheet paper-based technology, which is applied to tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of rough and irritating sensory quality, and achieve the effects of less miscellaneous gas, wide application prospect and natural aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] S1. Slurry preparation

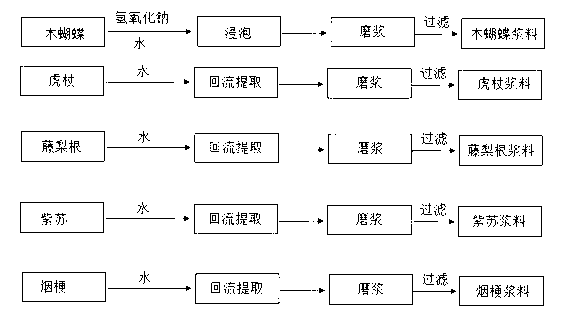

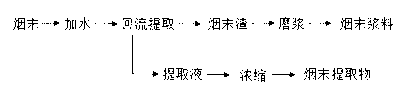

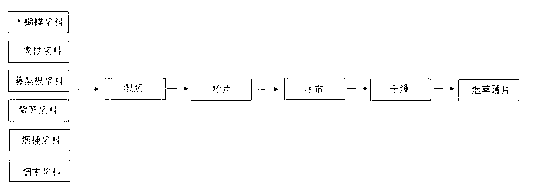

[0035] as attached figure 1 As shown, prepare wood butterfly pulp, knotweed pulp, rattan pear root pulp, perilla pulp and tobacco stem pulp respectively; as attached figure 2 As shown, prepare tobacco powder extract (tobacco powder extract) and tobacco powder slurry;

[0036] Wherein, solid sodium hydroxide and water are added to the Chinese herbal medicine Orchid Butterfly, the quality of solid sodium hydroxide is 5% of the quality of Orchard Butterfly, the quality of water is 5 times of the quality of Orchard Butterfly, soaked for 4 days, filtered, and the filter residue is defibrinated to obtain Wood butterfly paste.

[0037] Adding water with 4 times the mass of Polygonum cuspidatum to Polygonum cuspidatum, reflux extraction for 4 hours, taking the filter residue and grinding to obtain Polygonum cuspidatum slurry.

[0038] Add 4 times the weight of the wisteria root to the wisteria root, reflux and extract for 4 hours, take the filter r...

Embodiment 2

[0051] S1. Slurry preparation

[0052] Refer to the slurry preparation of Example 1.

[0053] S2. Mix the slurry, mix each slurry evenly according to the ratio in Table 2

[0054] Table 2 Mixing ratio

[0055] slurry Slurry ratio (by dry basis) wood butterfly 15% Knotweed 10% Vines 15% perilla 10% Tobacco stem 20% Tobacco powder 30%

[0056] Papermaking and coating refer to the method of Example 1 to obtain a moisture-retaining tobacco sheet.

Embodiment 3

[0058] The slurry preparation, papermaking and coating steps refer to Example 1, and the slurry mixing ratio is implemented according to Table 3.

[0059] Table 3 Mixing ratio

[0060] slurry Slurry ratio (by dry basis) wood butterfly 15% Knotweed 10% Vines 15% perilla 10% Tobacco stem 30% Tobacco powder 20%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com