Method for processing black tea with osmanthus fragrance by fresh tea leaves in summer and autumn

A technology for fresh tea leaves and sweet-scented osmanthus, which is applied in the field of processing sweet-scented sweet-scented sweet-scented tea with fresh leaves of summer and autumn tea, can solve the problems of blocking the export of black tea, waste of resources and the like, and achieve the effects of prominent sweet-scented sweet-scented tea, low processing cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

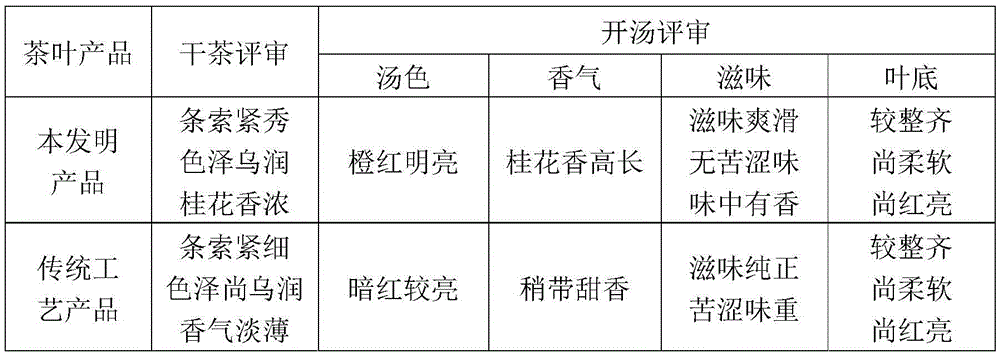

Image

Examples

Embodiment 1

[0033] The summer one-bud three-leaf tea fresh leaves of the tea tree variety Taoyuan Daye are selected as raw materials.

[0034] Preparation of natural osmanthus essential oil: using dried osmanthus flowers as raw materials, using HA121-50-05 supercritical CO 2 The extraction equipment extracts dried sweet-scented osmanthus flowers under the process conditions of extraction temperature 35°C, extraction pressure 35Mpa, separation temperature 45°C, and separation time 50 minutes to obtain the product.

[0035] Osmanthus fragrans water extract concentrated solution preparation: with above-mentioned supercritical CO 2 The osmanthus fragrans residue after the natural osmanthus fragrans essential oil was obtained by extraction technology was used as the raw material, and pure water was used as the extraction solvent. According to the ratio of 1g osmanthus fragrans residue to 15ml pure water, pure water was added to the osmanthus fragrans residue and extracted at 80°C for 45min, an...

Embodiment 2

[0039] The autumn one-bud and two-leaf fresh leaves of the tea tree varieties Zheng and Dabai are selected as raw materials.

[0040] Preparation of natural osmanthus essential oil: using dried osmanthus flowers as raw materials, using HA121-50-05 supercritical CO 2 The extraction equipment extracts dried sweet-scented osmanthus flowers under the process conditions of extraction temperature 30°C, extraction pressure 30Mpa, separation temperature 40°C, and separation time 55min to obtain the product.

[0041] Osmanthus fragrans water extract concentrated solution preparation: with above-mentioned supercritical CO 2 The osmanthus fragrans residue after the natural osmanthus fragrans essential oil is obtained by extraction technology is used as raw material, and pure water is used as the extraction solvent. According to the ratio of 1g osmanthus fragrans residue to 14ml pure water, pure water is added to the osmanthus fragrans residue and extracted at 75°C for 50min, and the extr...

Embodiment 3

[0045] The autumn one-bud three-leaf tea leaves of the tea tree variety Fuyun No. 6 are selected as raw materials.

[0046] Preparation of natural osmanthus essential oil: using dried osmanthus flowers as raw materials, using HA121-50-05 supercritical CO 2 The extraction equipment extracts dried sweet-scented osmanthus flowers under the process conditions of extraction temperature 40°C, extraction pressure 40Mpa, separation temperature 50°C, and separation time 45min to obtain the product.

[0047] Osmanthus fragrans water extract concentrated solution preparation: with above-mentioned supercritical CO 2 The osmanthus fragrans residue after the natural osmanthus fragrans essential oil is obtained by extraction technology is used as raw material, and pure water is used as the extraction solvent. According to the ratio of 1g osmanthus fragrans residue to 16ml pure water, pure water is added to the osmanthus fragrans residue and extracted at 85°C for 40min, and the extract is sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com