Process and apparatus to obtain tobacco flavor extracts

A spice extract and tobacco technology, applied in the field of obtaining spice extract, to achieve the effect of low environmental problems and good factory operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

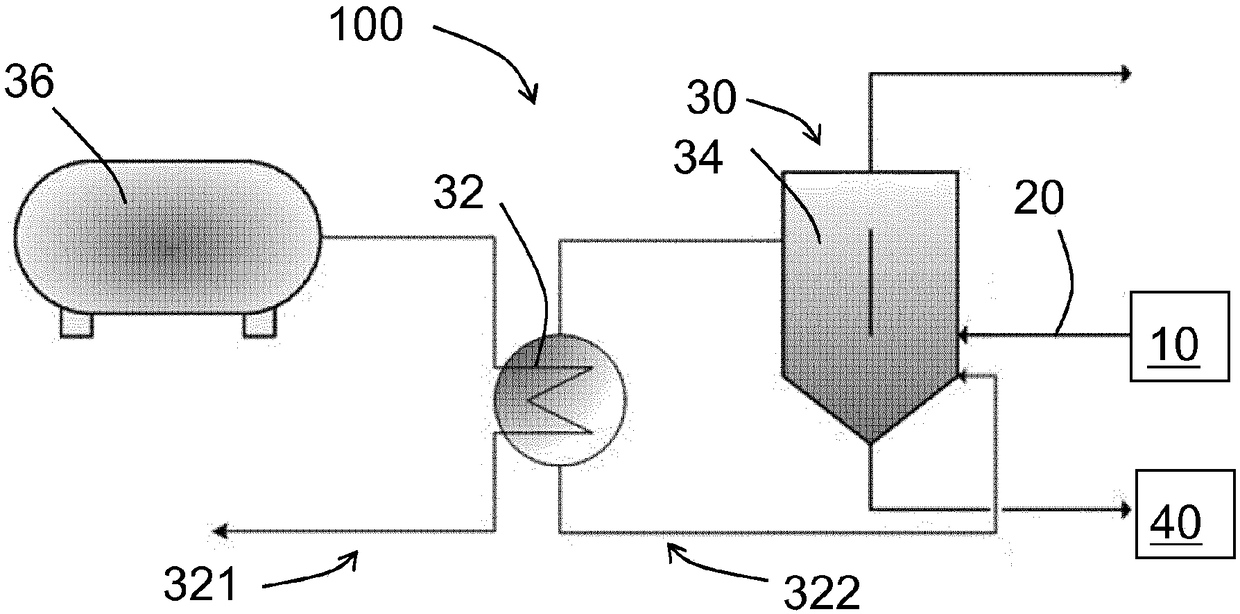

[0055] Specifically, figure 1 A first embodiment of a device for obtaining a tobacco flavor extract is shown, generally indicated with the reference number 100 .

[0056] The apparatus 100 comprises a direct conditioning drum 10 suitable for conditioning a mixture of tobacco leaves, stems and blades in a tobacco primary manufacturing line.

[0057] In the direct conditioning drum 10, the dry mixture of tobacco leaves, stems and blades is exposed to heat and humidity to open and toughen its structure for further processing. For example, steam and hot water are sprayed in a counter-current fashion on a mixture of tobacco leaves, stems and leaves.

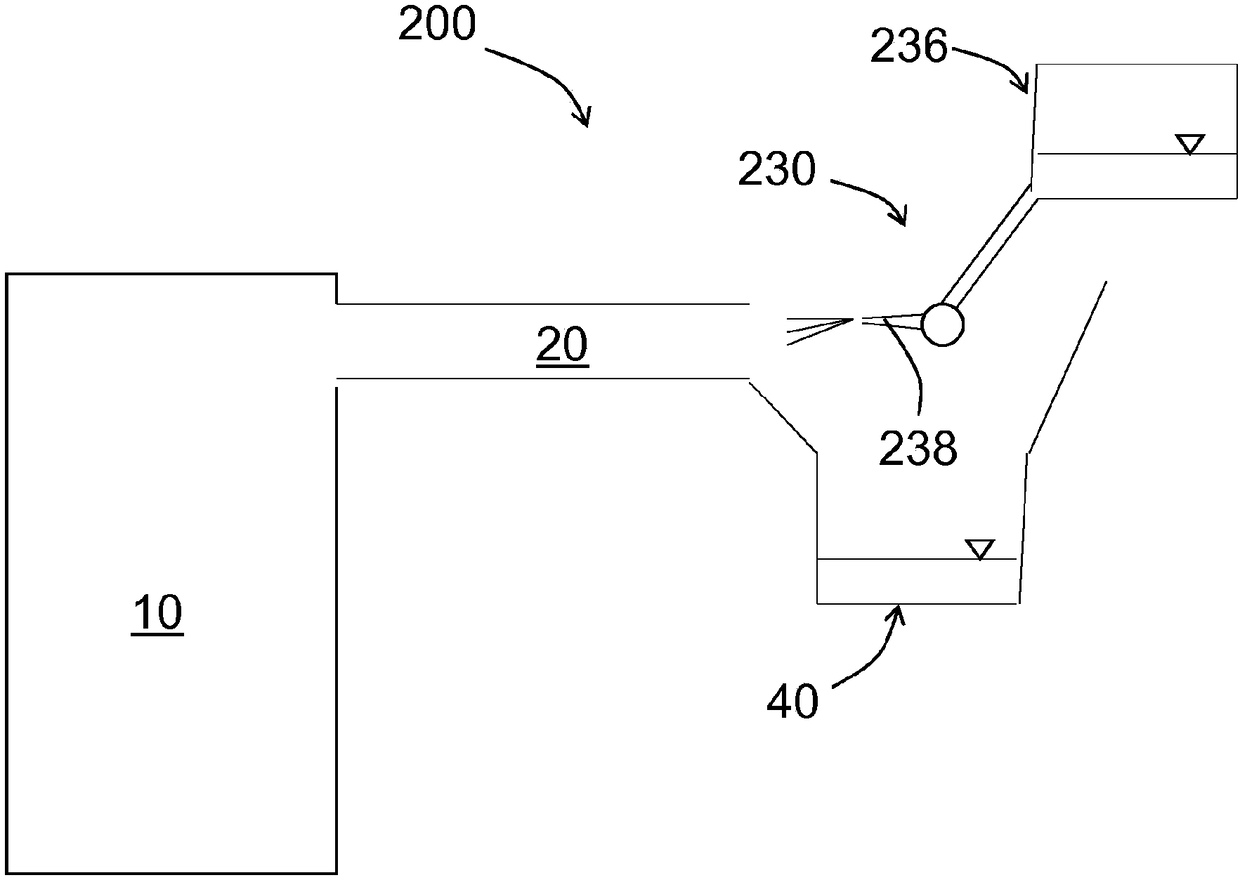

[0058] The direct conditioning drum 10 includes an exhaust pipe 20 . The exhaust pipe 20 is adapted to discharge emissions from the rehydrated mixture.

[0059] The device 100 also includes a condensation system 30 . A condensing system 30 is fluidly connected to the exhaust pipe 20 . The condensing system 30 is adapted to reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com