Device and process for preparing sulfur dioxide gas by continuously combusting raw sulfur

A technology for sulfur dioxide and sulfur generation, which is used in sustainable manufacturing/processing, chemical industry, sulfur compounds, etc., can solve the problems of complex process steps, insufficient incineration, and high production costs, and achieve reliable system operation, good economic benefits, and production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

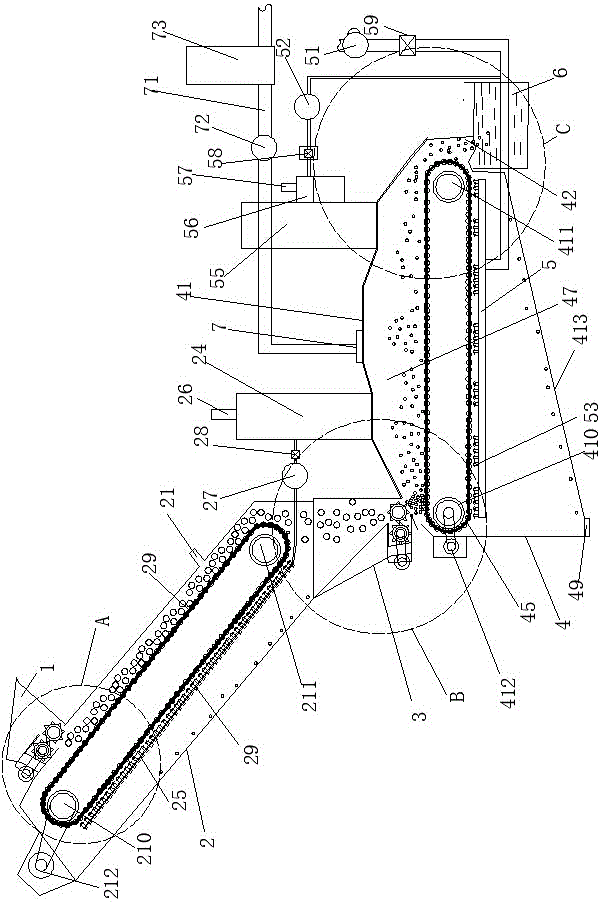

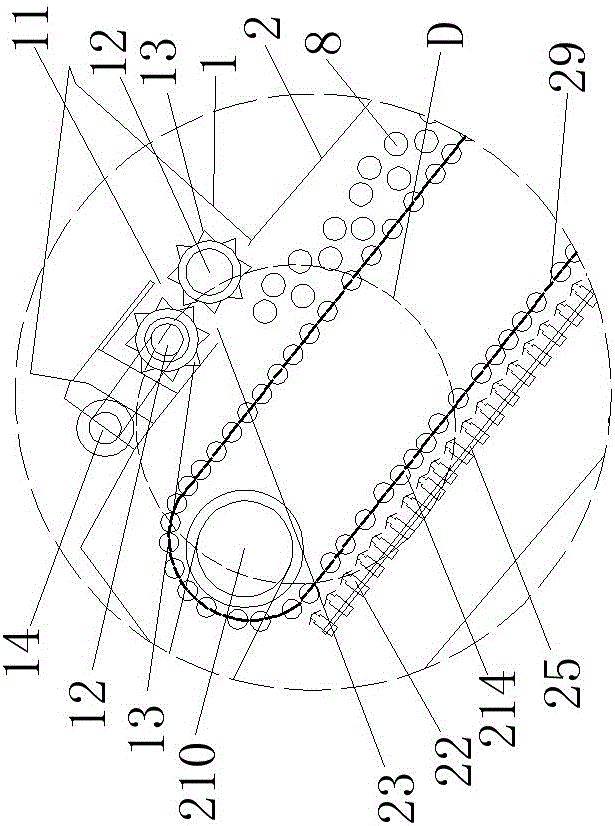

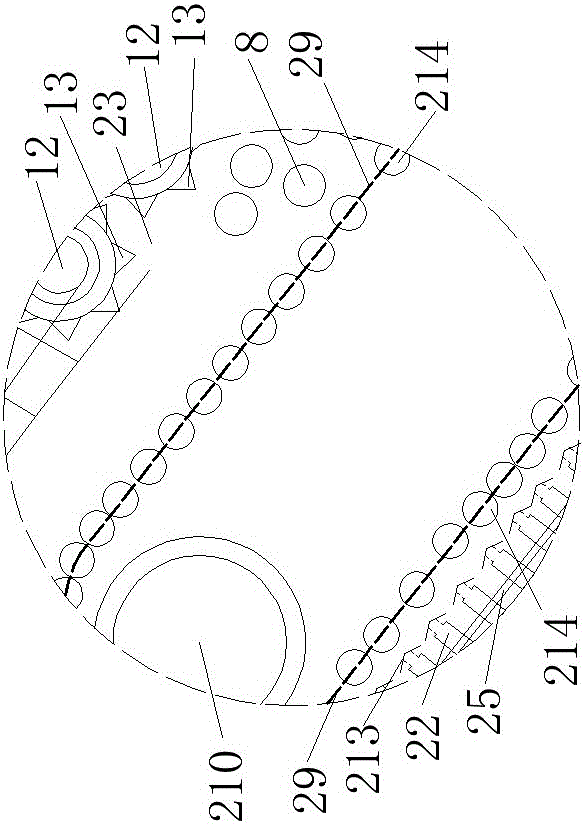

[0041] Example 1. like Figure 1 to Figure 6 As shown, a device that can continuously incinerate sulfur to produce sulfur dioxide gas includes a first feeding system, a drying system, a second feeding system, an incineration system, a slag discharge system, and a gas collection system.

[0042] The first feeding system includes a first feeding funnel 1, and an extruding device is arranged on the bottom opening 11 of the first feeding funnel. The purpose of installing the extruding device is to extrude the raw sulfur into strips or blocks, and quantitatively and continuously input the raw sulfur to the drying system.

[0043] The drying system includes a drying chamber 2, a second transmission device, and a drying device; the drying chamber 2 is provided with a feed port 23 and an exhaust port 21; the feed port 23 of the drying chamber 2 is connected to the first feed The bottom opening 11 of the funnel is connected; the drying device includes a hot-air nozzle 22 and a second...

Embodiment 2

[0061] Example 2. The process of preparing sulfur dioxide gas by adopting the device that can continuously burn sulfur to prepare sulfur dioxide gas described in embodiment 1 may further comprise the steps:

[0062] Step 1: Continuously pour raw sulfur into the first feeding hopper 1, turn on the extruding device, extrude the raw sulfur into raw sulfur bars or raw sulfur blocks, and the extruded raw sulfur bars or raw sulfur blocks enter the drying system . The raw sulfur is extruded into raw sulfur strips or raw sulfur blocks for easy drying.

[0063] Step 2: Dry the raw sulfur strips or raw sulfur blocks in the drying system, so that the water content of the raw sulfur strips or raw sulfur blocks reaches below 10%; the dried sulfur strips or raw sulfur blocks enter the second stage The feed hopper 3 and the crushing device crush the dried sulfur strips or blocks into sulfur fragments; the sulfur fragments enter the feed port 43 of the furnace body 4 and fall onto the sheet...

Embodiment 3

[0065] Example 3. The process of preparing sulfur dioxide gas by adopting the device that can continuously burn sulfur to prepare sulfur dioxide gas described in embodiment 1 may further comprise the steps:

[0066] Step 1: Continuously pour raw sulfur into the first feeding hopper 1, turn on the extruding device, extrude the raw sulfur into raw sulfur bars or raw sulfur blocks, and the extruded raw sulfur bars or raw sulfur blocks enter the drying system .

[0067] Step 2: Dry the raw sulfur strips or raw sulfur blocks in the drying system, so that the water content of the raw sulfur strips or raw sulfur blocks reaches below 15%; the dried sulfur strips or raw sulfur blocks enter the second stage The feed hopper 3 and the crushing device crush the dried sulfur strips or blocks into sulfur fragments; the sulfur fragments enter the feed port 43 of the furnace body 4 and fall onto the sheet 46 of the first transmission chain 45 .

[0068] Step 3: Light the raw sulfur fragment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com