Method for measuring release rate of non-polar or low-polar flavor component in smoke-free tobacco product

A technology for smokeless tobacco and aroma components, applied in the field of tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

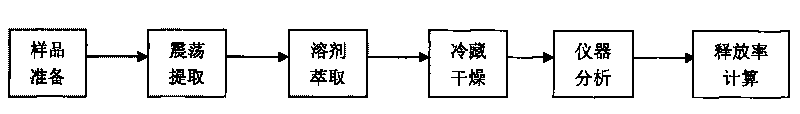

Method used

Image

Examples

Embodiment 1

[0023] 1. Sample preparation: prepare artificial saliva and 150ppm methyl nicotinate (standard, chromatographically pure) dichloromethane solution;

[0024] 2. Weigh 0.5g of two smokeless tobacco products of equal mass and put them in a 50ml Erlenmeyer flask, add 10ml artificial saliva to one part and 10ml dichloromethane solution in the other part, and seal the Erlenmeyer flask, then Oscillate for 20 minutes at a speed of 120 rpm;

[0025] 3. Extract the saliva extracts of smokeless tobacco products with methyl nicotinate (standard) methylene chloride solution twice, 5ml each time, and combine the extracts;

[0026] 4. Add 5g of anhydrous sodium sulfate to the dichloromethane extract, refrigerate for 12h and concentrate to 1ml;

[0027] 5. Instrument analysis: Chromatographic column: DB-WAXER (30m×0.25mmi.d.×0.25μmd.f.)

[0028] Detector: NPD

[0029] Carrier gas, flow rate: N2, 1.8ml / min

[0030] Temperature of inlet and detector: 270℃

[0031] Heating program: 50℃(1min)2℃ / min→200℃;

[0...

Embodiment 2

[0039] 1. Sample preparation: prepare artificial saliva and 100ppm phenethyl acetate (standard) dichloromethane solution;

[0040] 2. Weigh two 0.9g portions of smokeless tobacco products of equal mass; put them in a 50ml Erlenmeyer flask, add 20ml artificial saliva to one portion, add 20ml dichloromethane solution to the other portion, and seal the Erlenmeyer flask, then Oscillate for 40 minutes at a speed of 200 rpm;

[0041] 3. Extract the saliva extracts of smokeless tobacco products with phenethyl acetate (standard, chromatographically pure) dichloromethane solution twice, 10ml each time, and combine the extracts;

[0042] 4. Add 10g of anhydrous sodium sulfate to the dichloromethane extract, refrigerate for 24h and concentrate to 1ml;

[0043] 5. Instrument analysis:

[0044] Chromatographic column: HP-5 capillary column (60m×0.2mm i.d.×0.33μm d.f.)

[0045] Detector: FID

[0046] Carrier gas, flow rate: N2, 0.8ml / min

[0047] Temperature of inlet and detector: 270℃

[0048] Heating ...

Embodiment 3

[0061] 1. Sample preparation: prepare artificial saliva and 50ppm phenethyl propionate (standard, chromatographically pure) dichloromethane solution;

[0062] 2. Weigh two 0.6g portions of smokeless tobacco products of equal mass and put them in a 50ml Erlenmeyer flask, add 16ml artificial saliva to one portion, and 16ml dichloromethane solution in the other portion, and seal the Erlenmeyer flask. Oscillate for 30 minutes at a speed of 150 rpm;

[0063] 3. Extract the saliva extract of smokeless tobacco products with phenethyl propionate (standard) dichloromethane solution twice, 8ml each time, and combine the extracts;

[0064] 4. Add 8g of anhydrous sodium sulfate to the dichloromethane extract, refrigerate for 18h and concentrate to 1ml;

[0065] 5. Instrument analysis: Capillary column: HP-INNOWAX 30m×0.25mmi.d×0.25μmd.f

[0066] Detector: FID

[0067] Carrier gas, flow rate: N2, 1.0ml / min

[0068] Inlet and detector temperature: 250℃, detector temperature 270℃

[0069] Heating progra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com