Fume-less cooker

A fume pot and pot body technology is applied to frying pans, utensils for frying things in oil, special materials for cooking utensils, etc. The effect of heating area, improving utilization rate and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

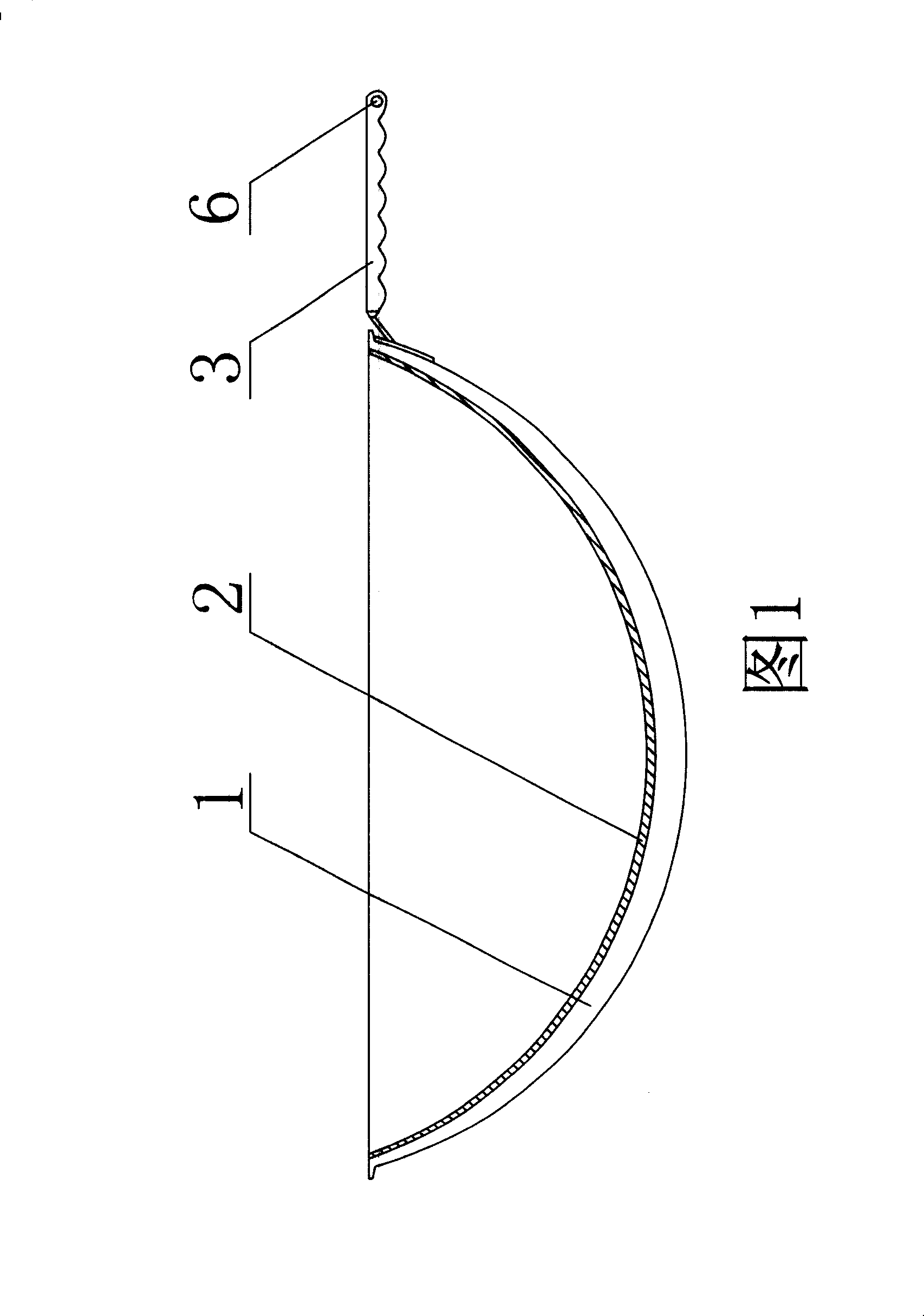

[0021] Figure 1 is a schematic cross-sectional view of the structure of the oil-free pot of the present invention; it includes a pot body 1 and a heat uniform layer 2 with a lower thermal conductivity than the pot body 1, and the heat uniform layer 2 is arranged on the inner surface of the pot body 1. The key of the present invention is that the thermal conductivity of the heat uniform layer 2 is lower than that of the pot body 1 to achieve uniform heat. The bottom of the pot body 1 is thick and the edges are thin. The overall thickness of the pot body 1 is 1-6mm, the bottom thickness is 3-6mm, and the edge thickness is 1-3mm. In this embodiment, the pot body 1 can be made of various metal alloy materials such as gold, silver, copper, magnesium, and aluminum. Among them, gold has a specific gravity of 19.302, a specific heat capacity of 128, and a thermal conductivity of 317.9; silver has a specific gravity of 10.49, a specific heat capacity of 235, and a thermal conductivity...

Embodiment 2

[0025] The difference between this embodiment and the first embodiment is mainly that the pot body 1 is preferably made of aluminum alloy or magnesium alloy, and the uniform heat layer 2 is preferably made of stainless steel, and the stainless steel is compounded on the inner surface of the aluminum alloy or magnesium alloy. The thermal conductivity of stainless steel is also lower than that of aluminum alloy and magnesium alloy, which can also achieve the effect of uniform heat. The aluminum alloy or magnesium alloy quickly absorbs the heat and transfers it to the stainless steel. Because the thermal conductivity of stainless steel is low, part of the heat cannot be absorbed, but diffuses to the surrounding, so that the temperature on the entire stainless steel layer rises at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com