Patents

Literature

49results about How to "Avoid fume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

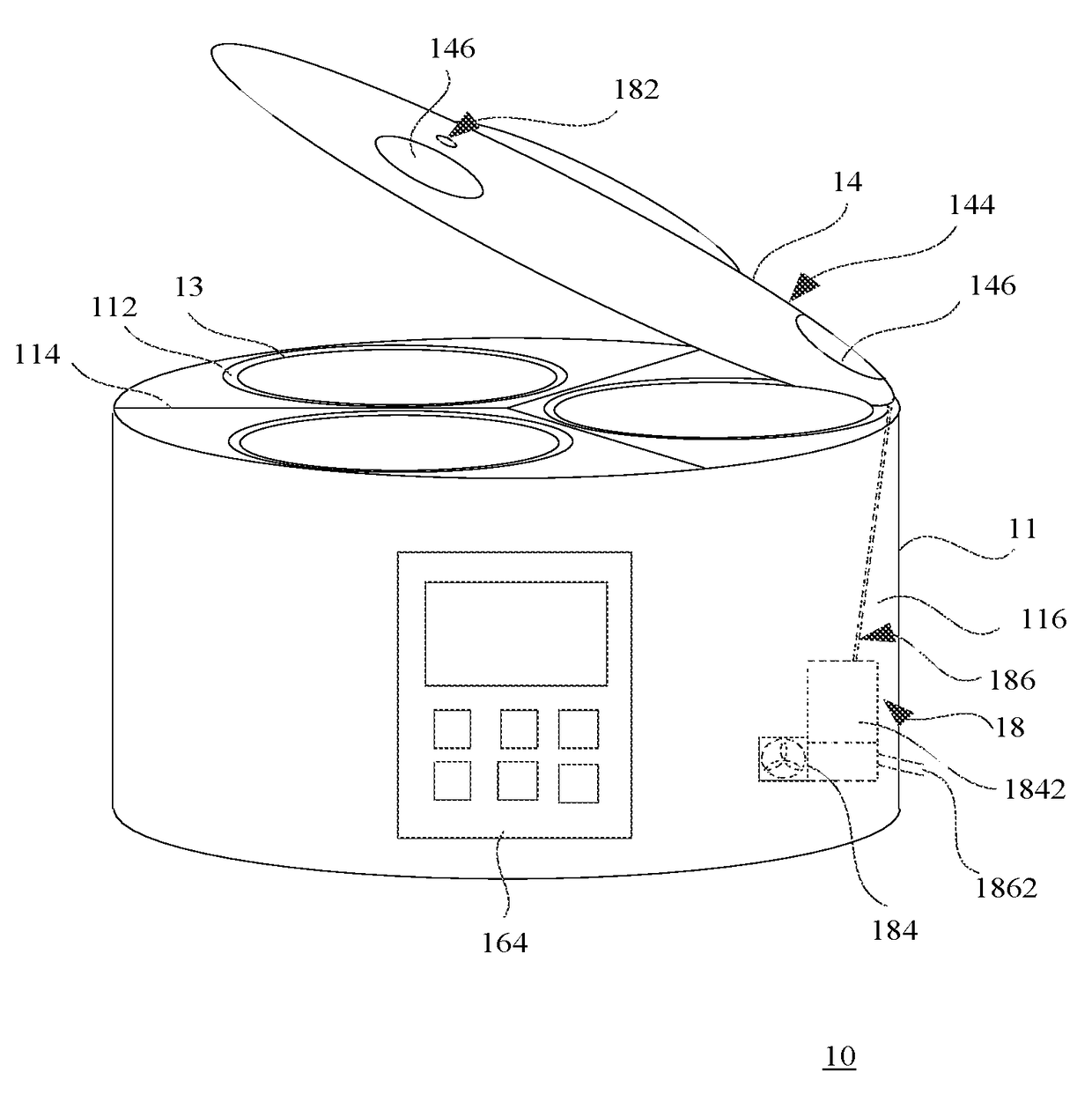

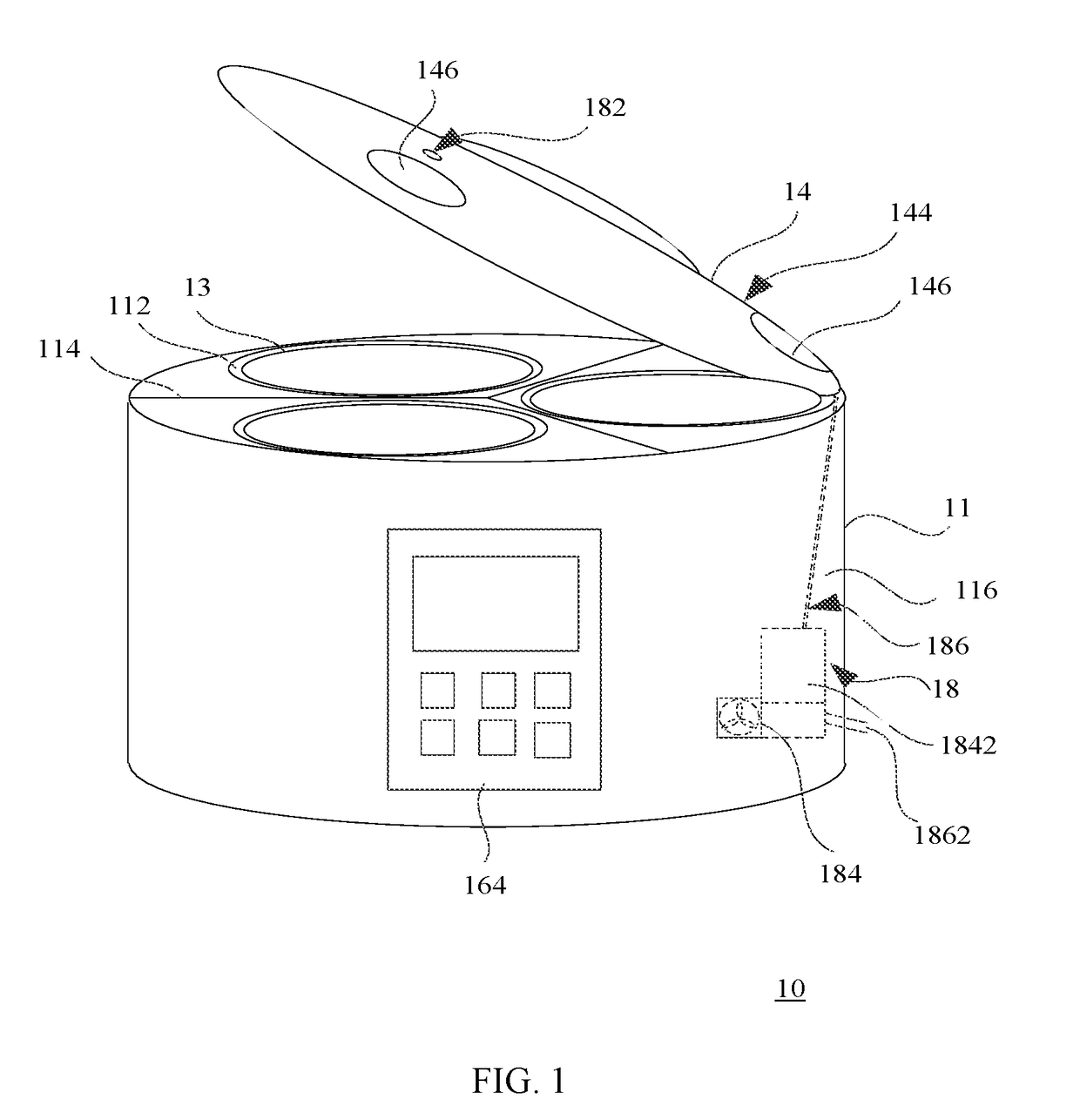

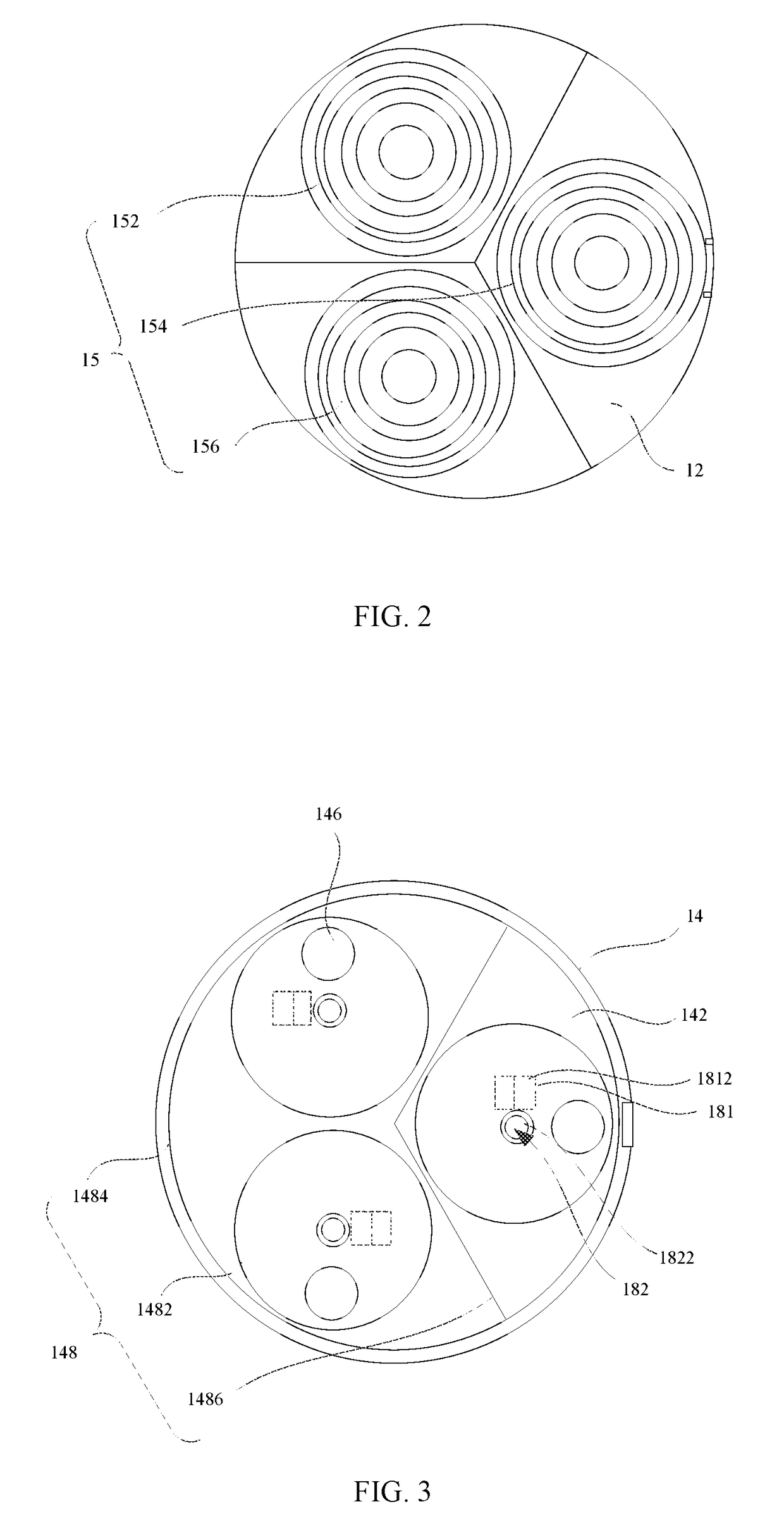

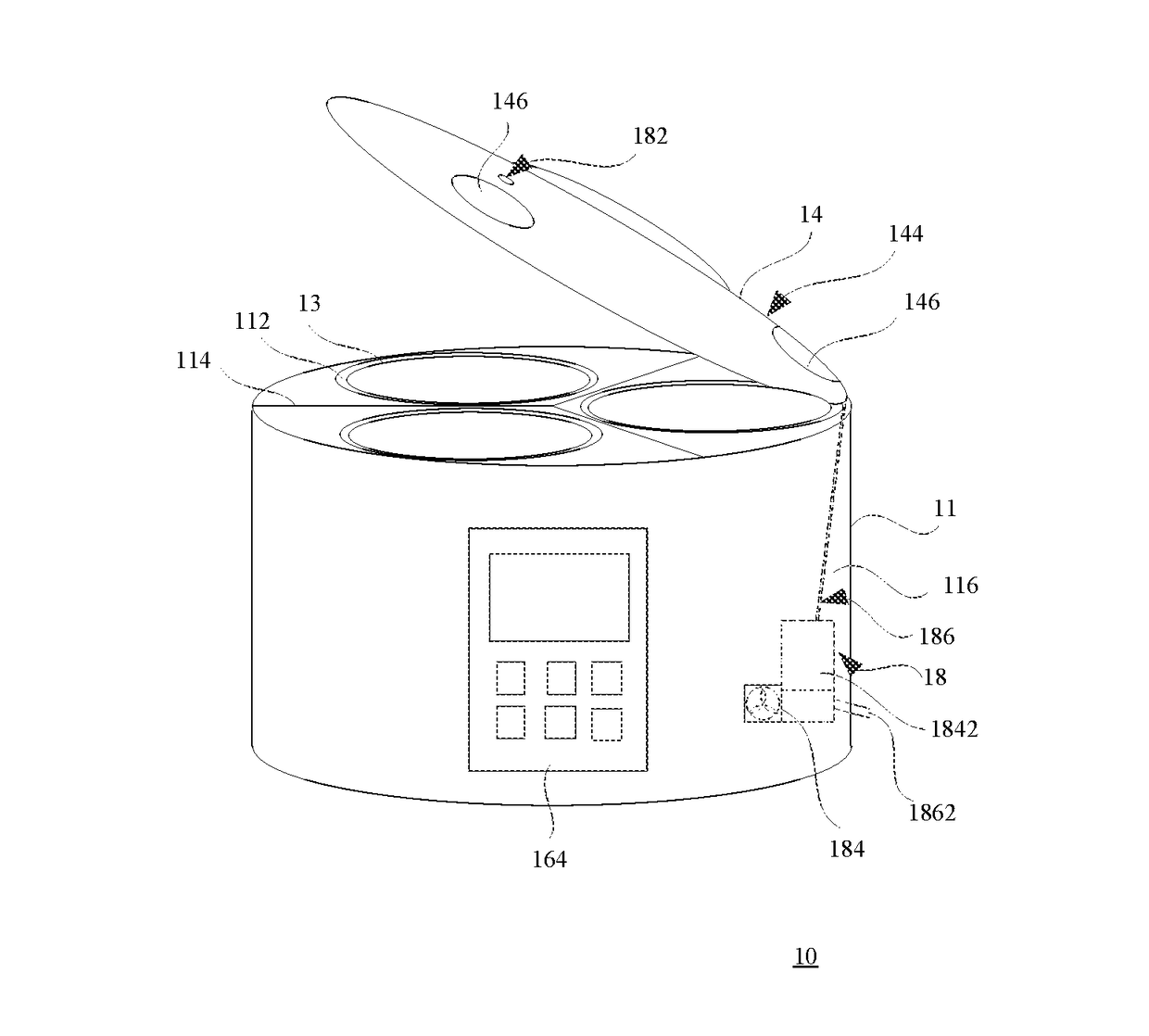

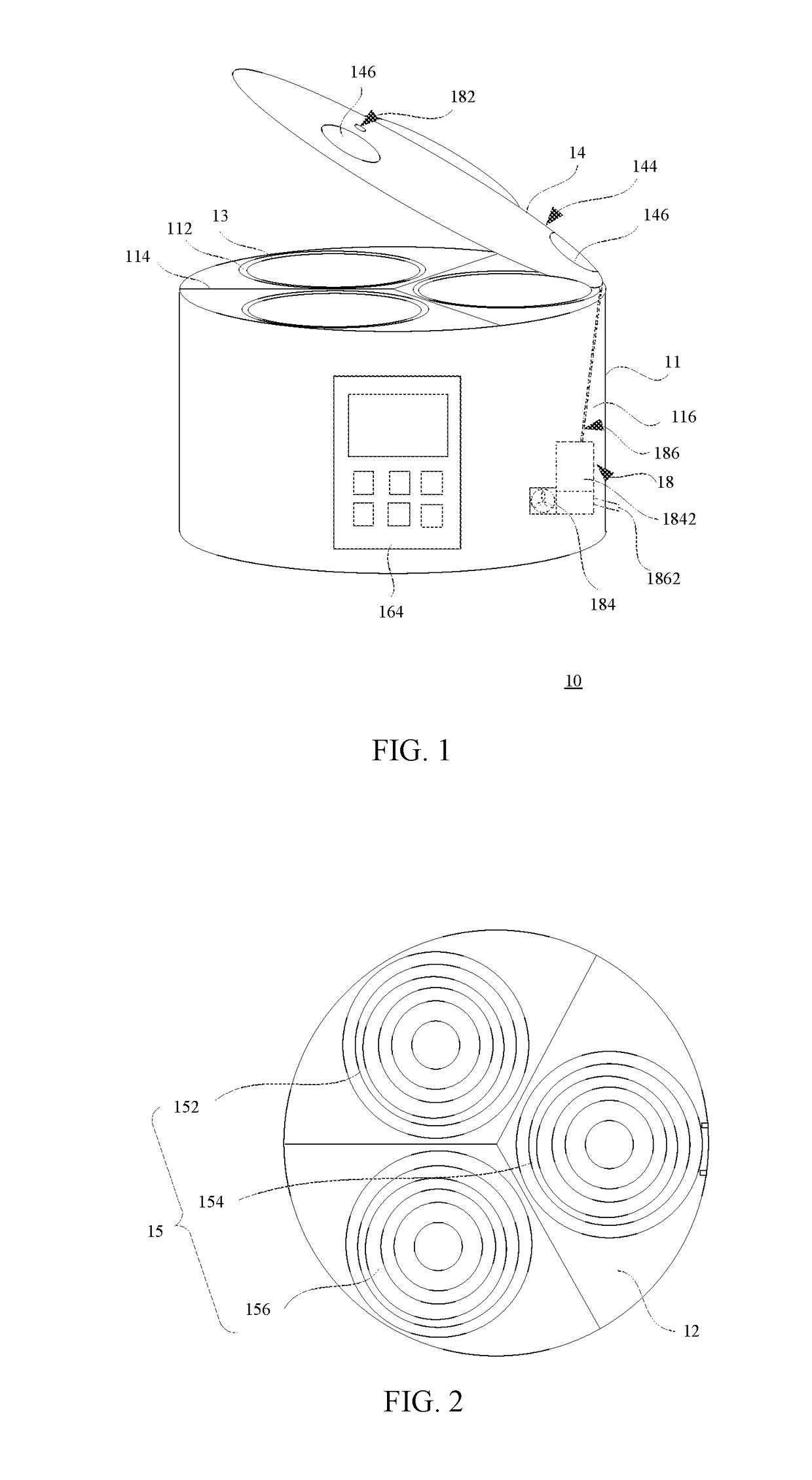

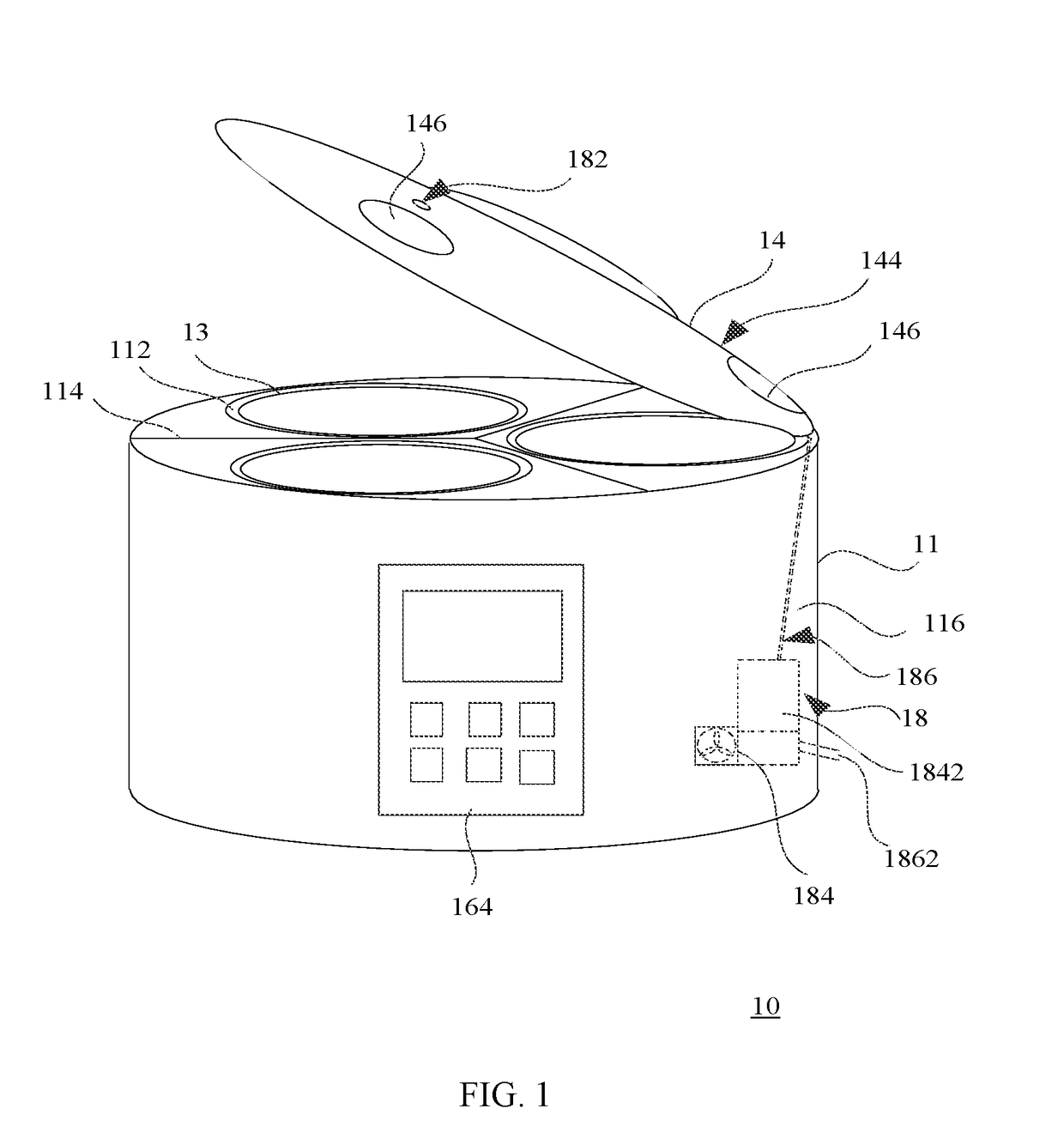

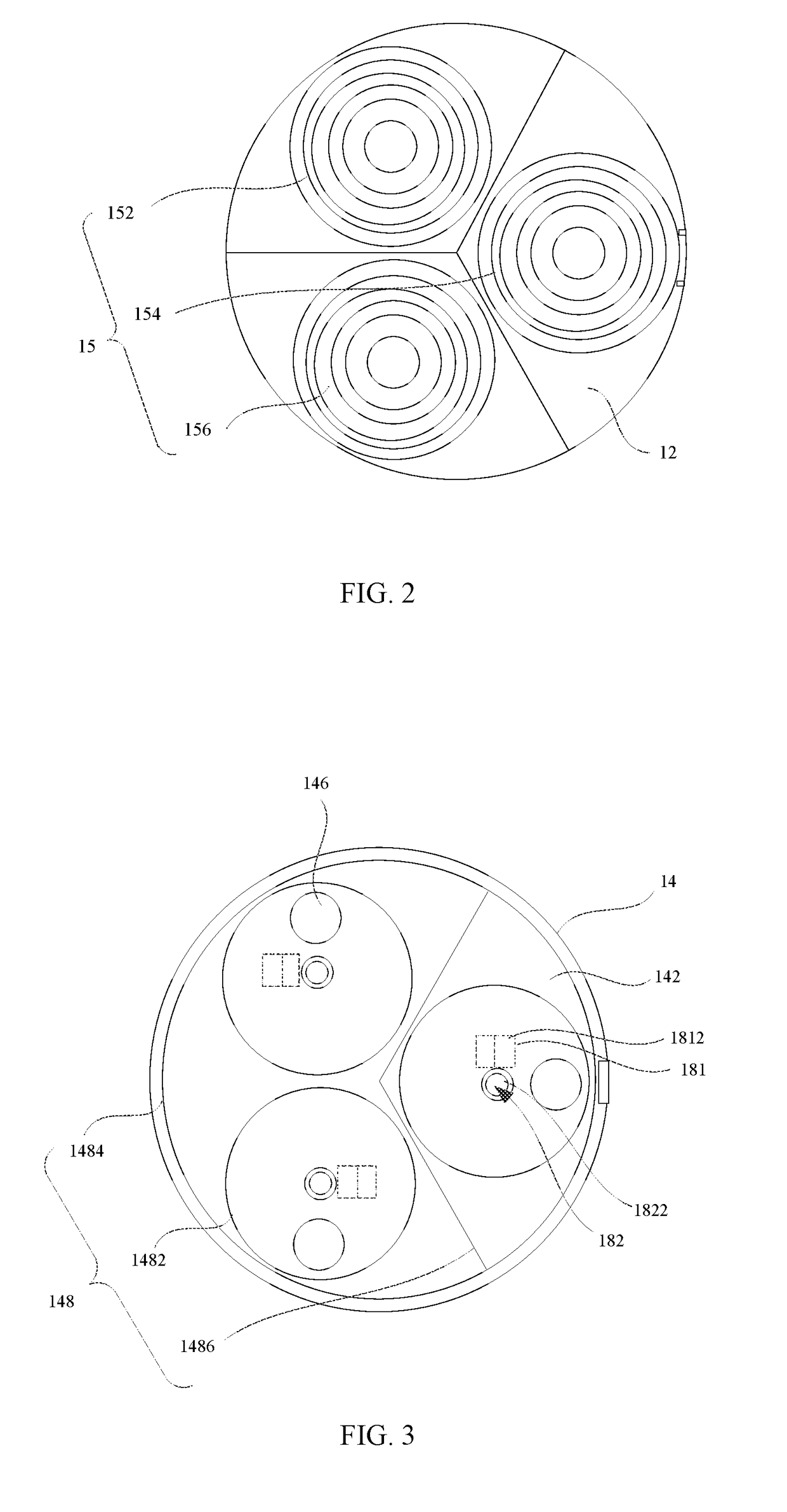

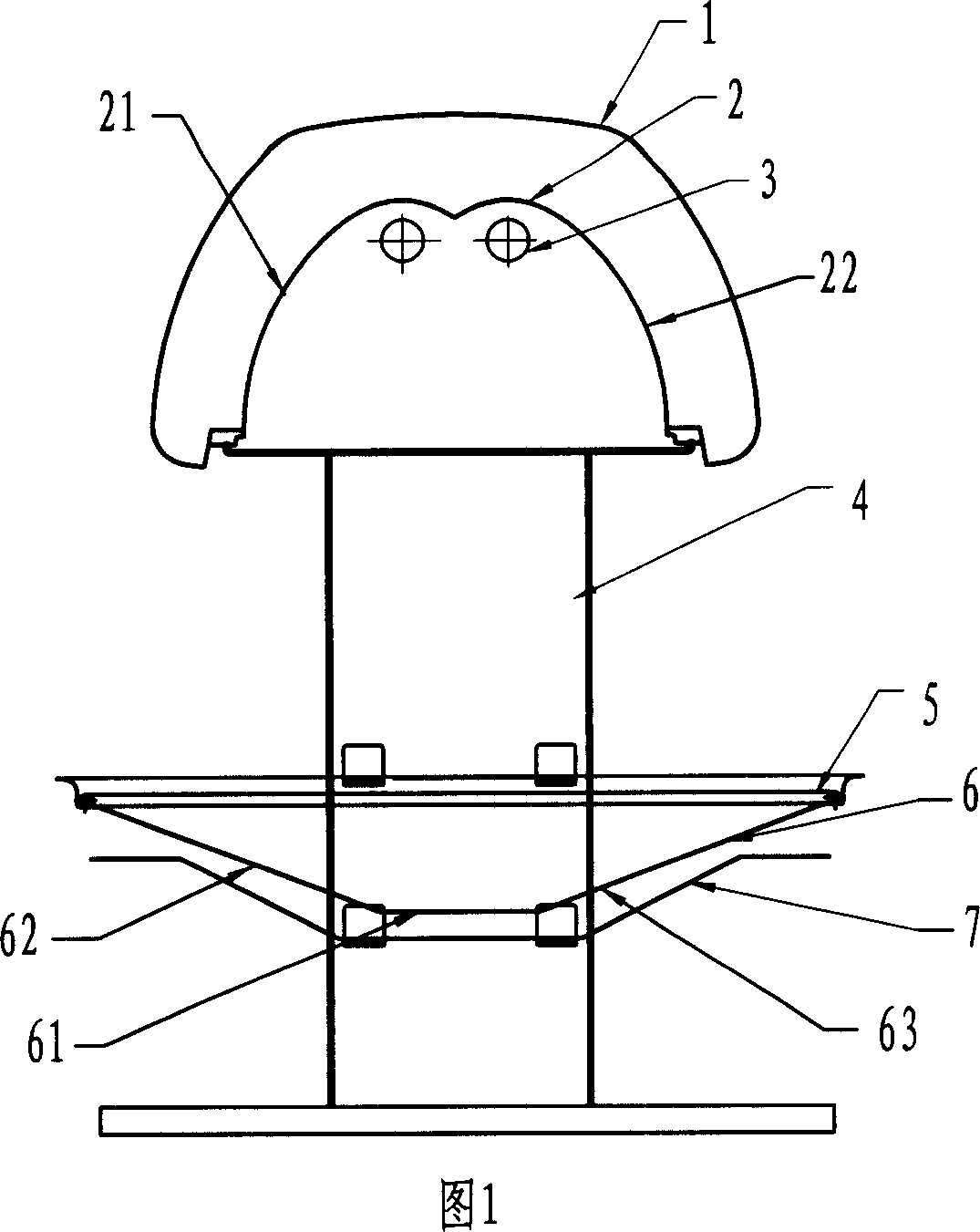

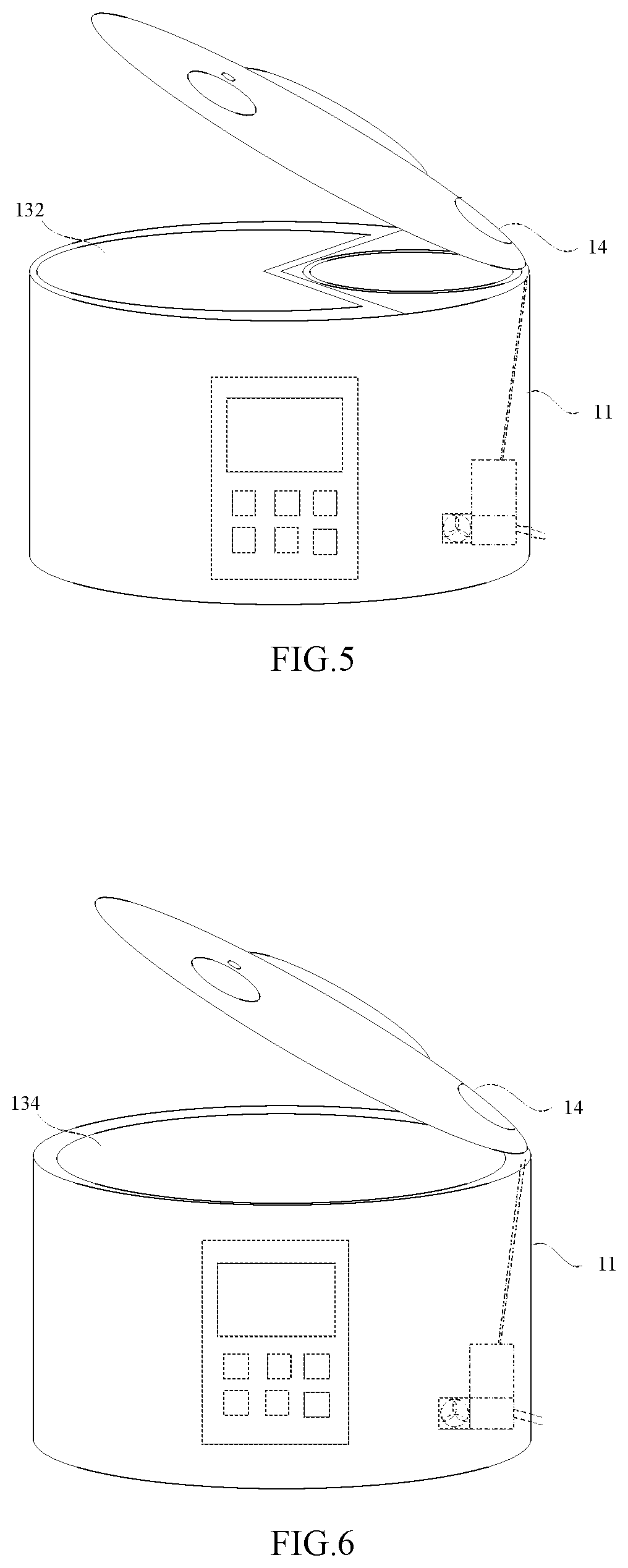

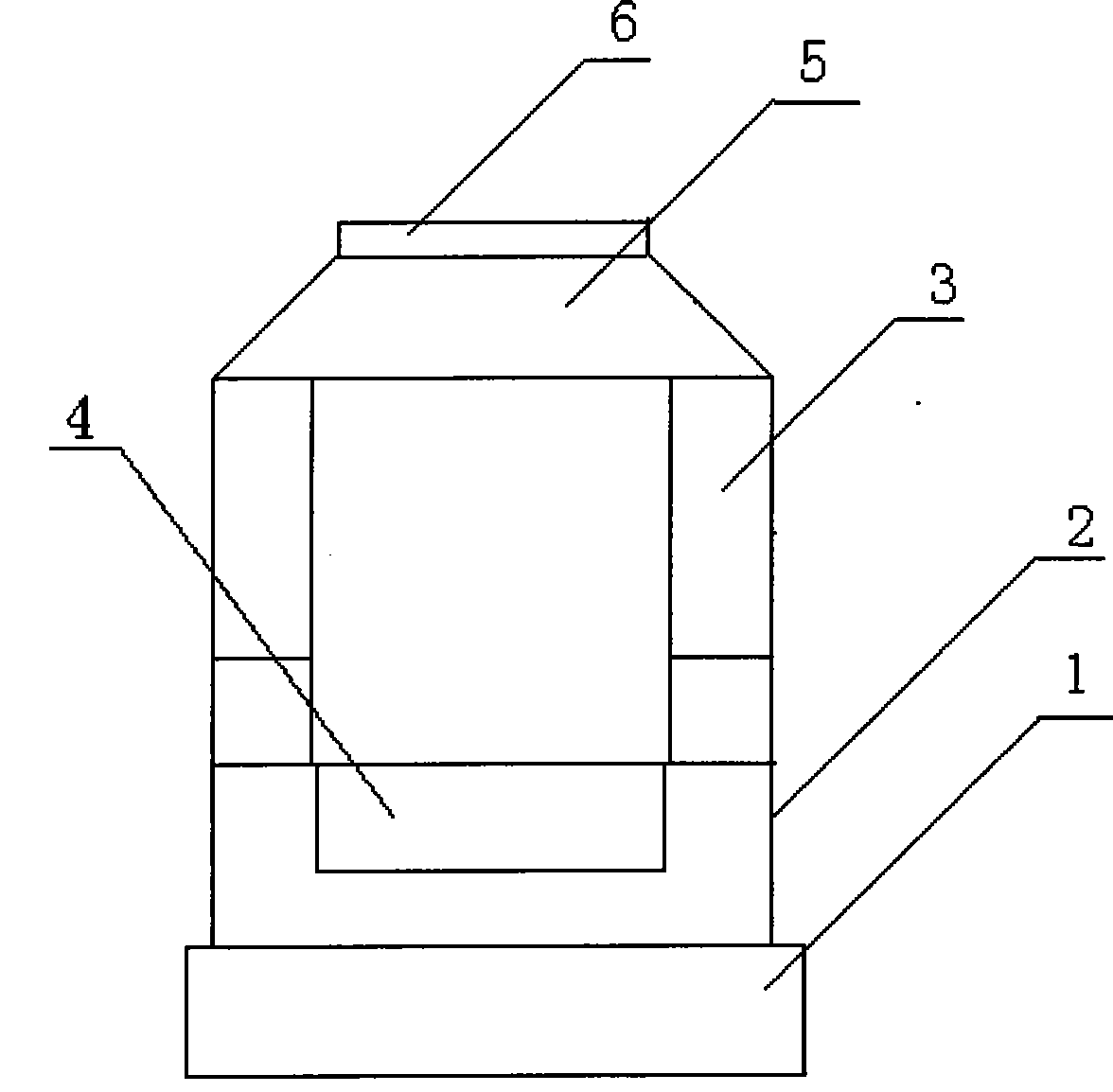

Cooking device with compact structure preventing oil fume

InactiveUS9795250B2Avoid fumeEasy to meetMultiple-unit cooking vesselsSteam cooking vesselsComputer moduleEngineering

Owner:SHENZHEN ZEZHI INTPROP CO LTD

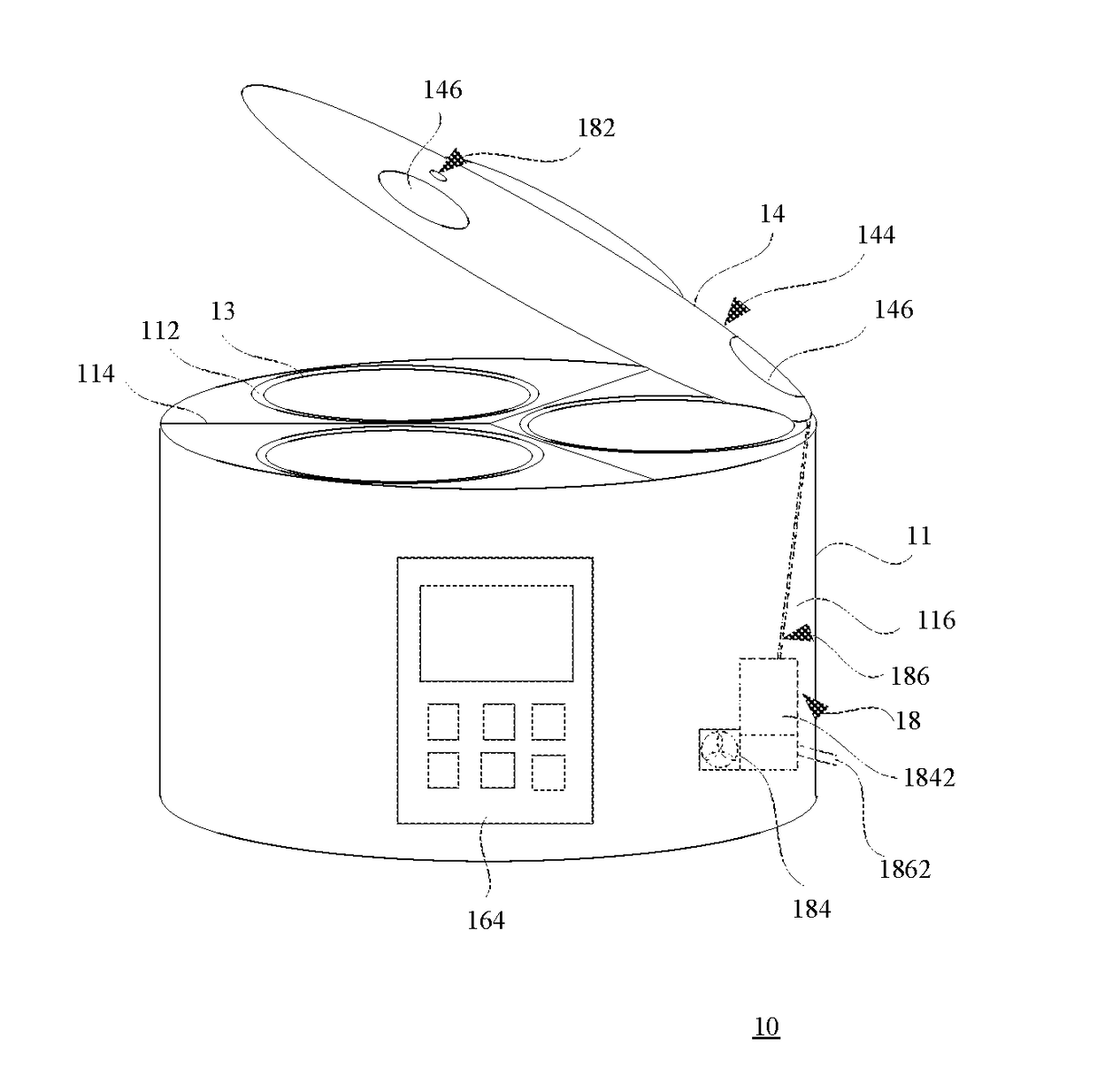

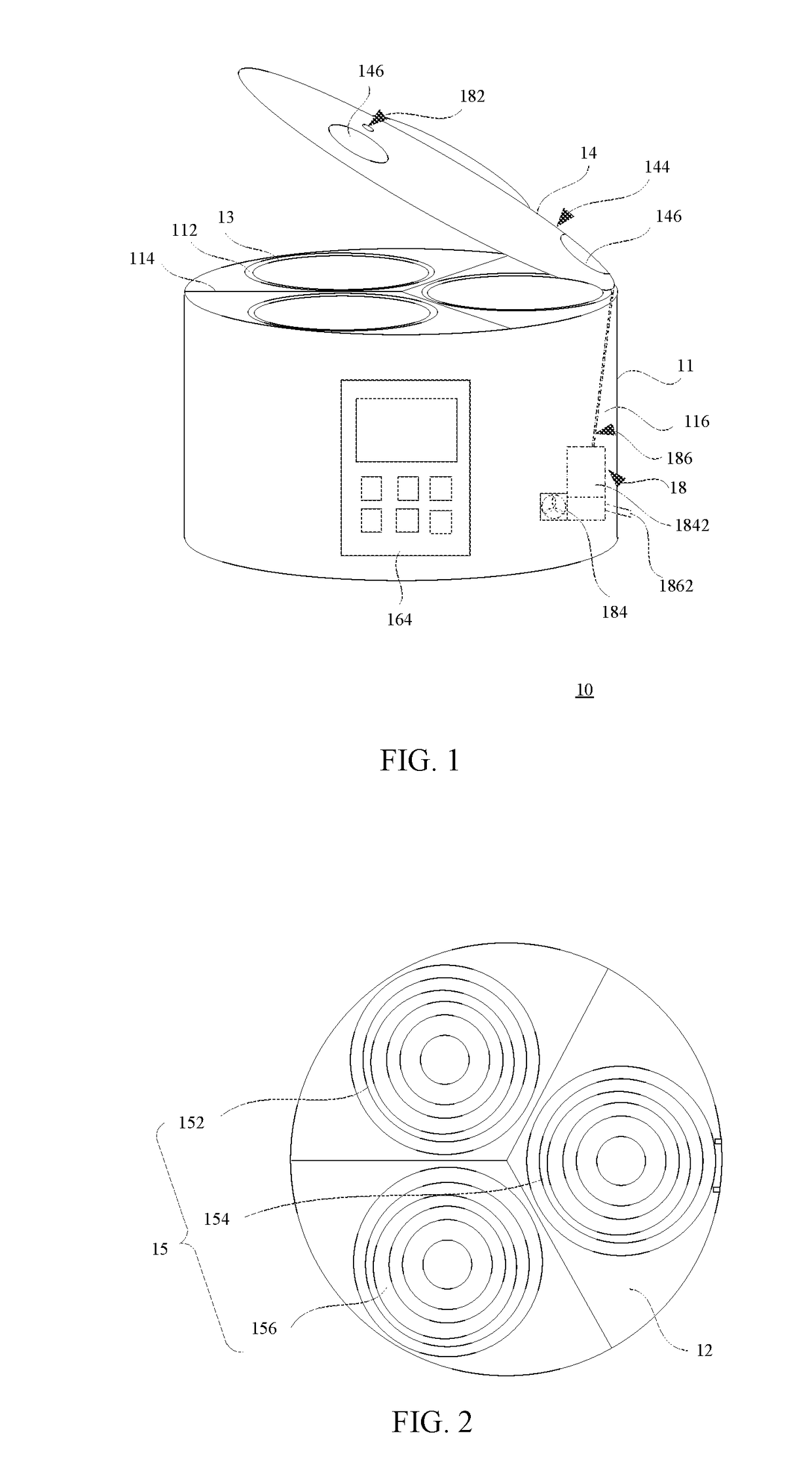

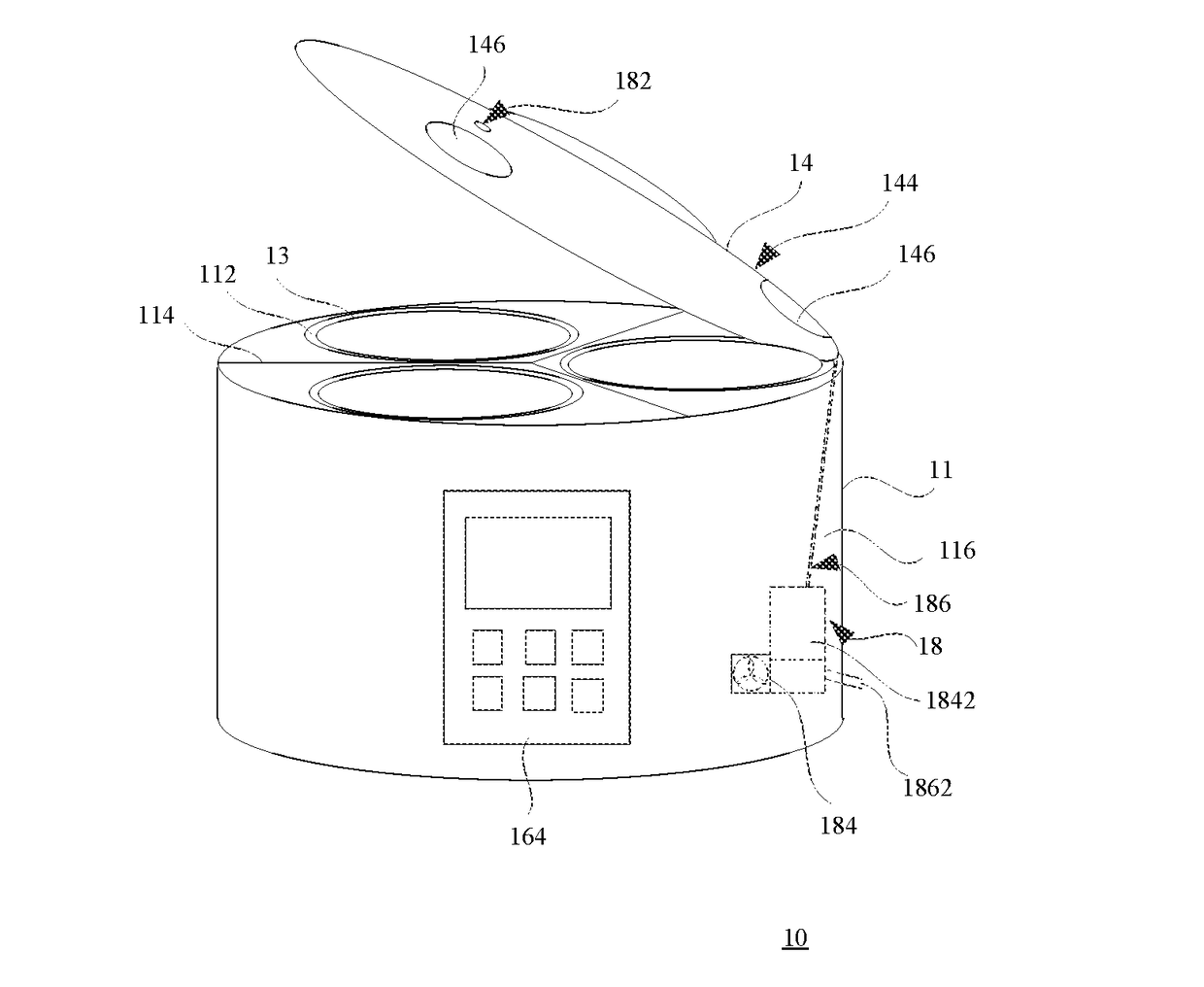

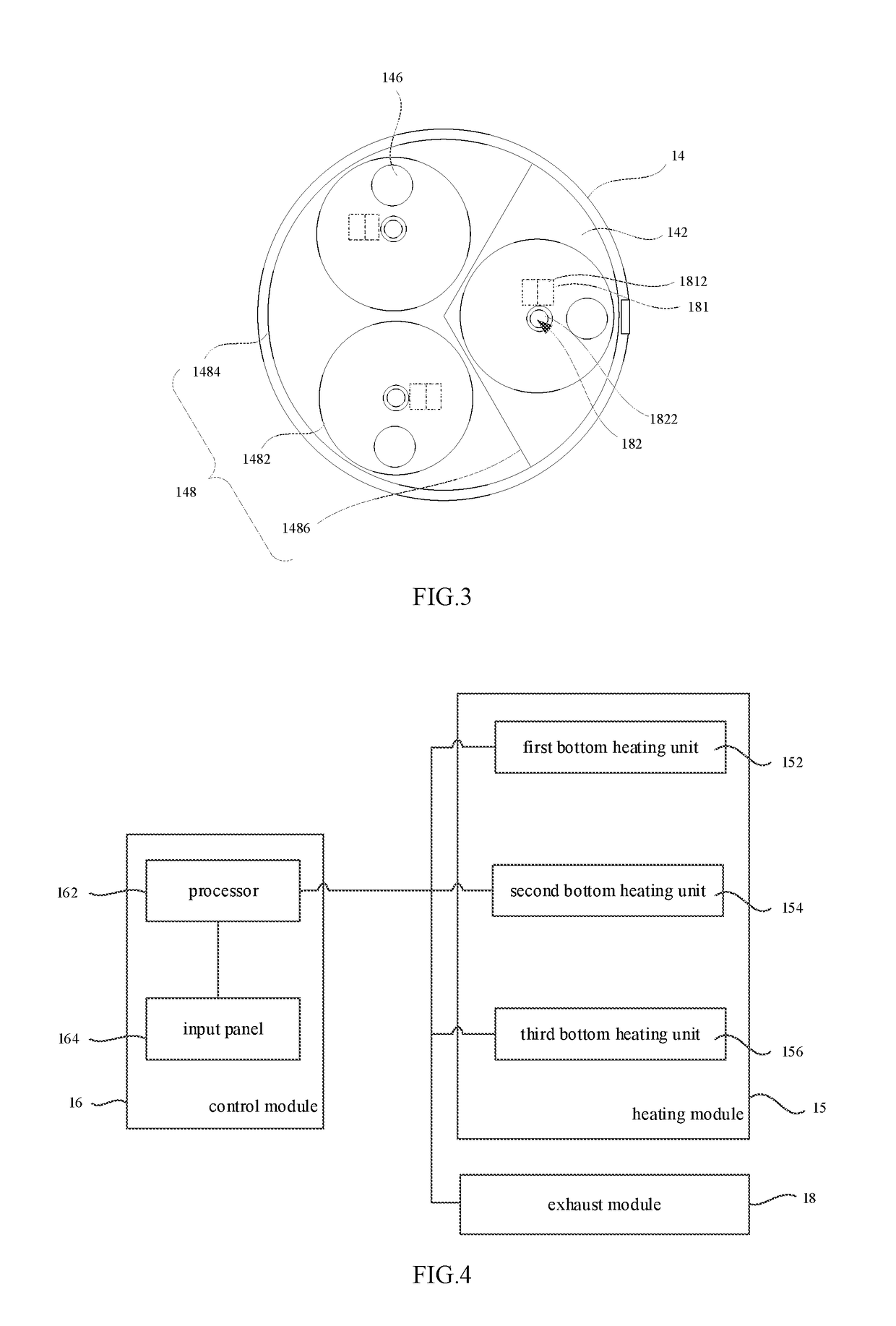

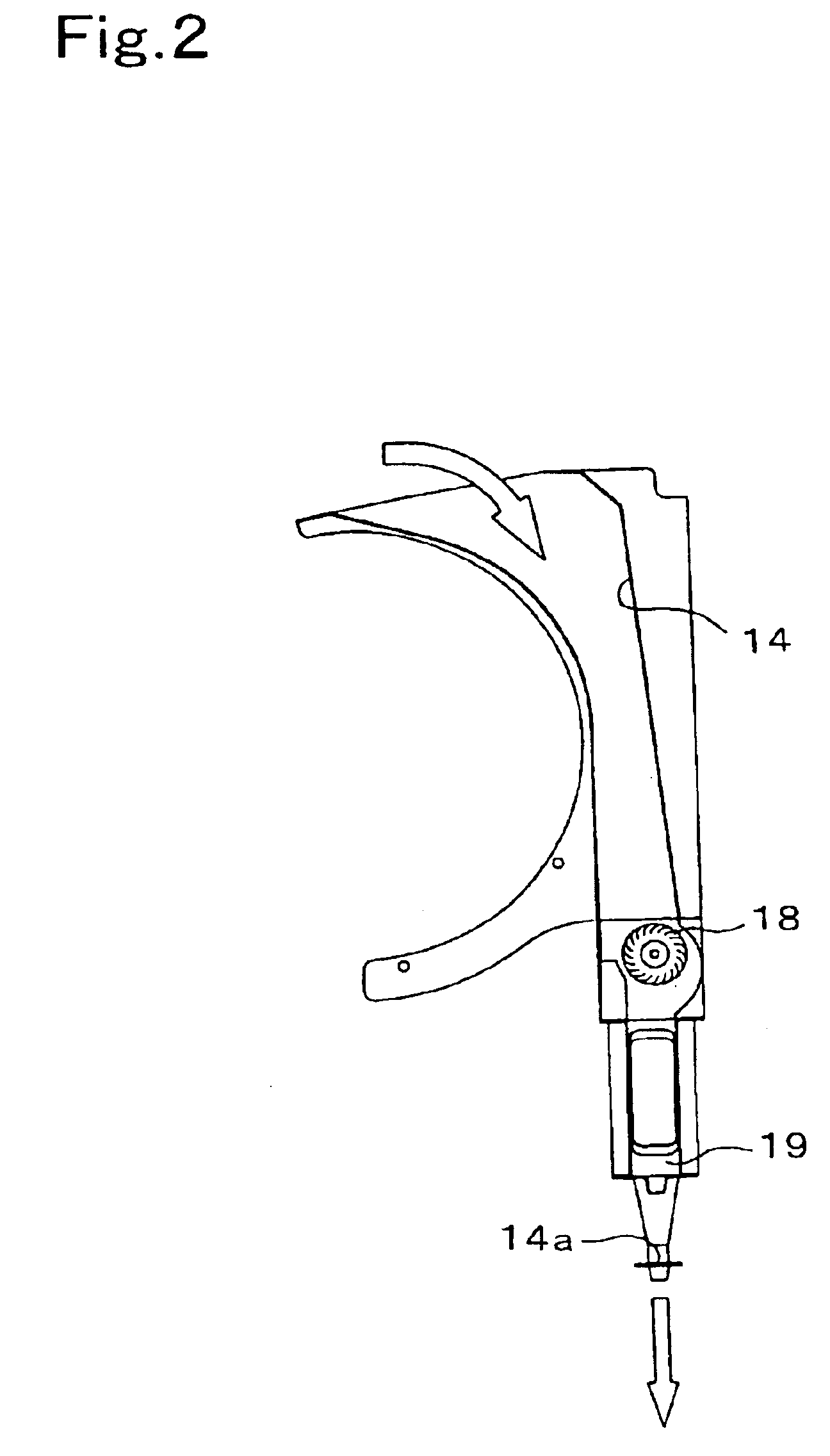

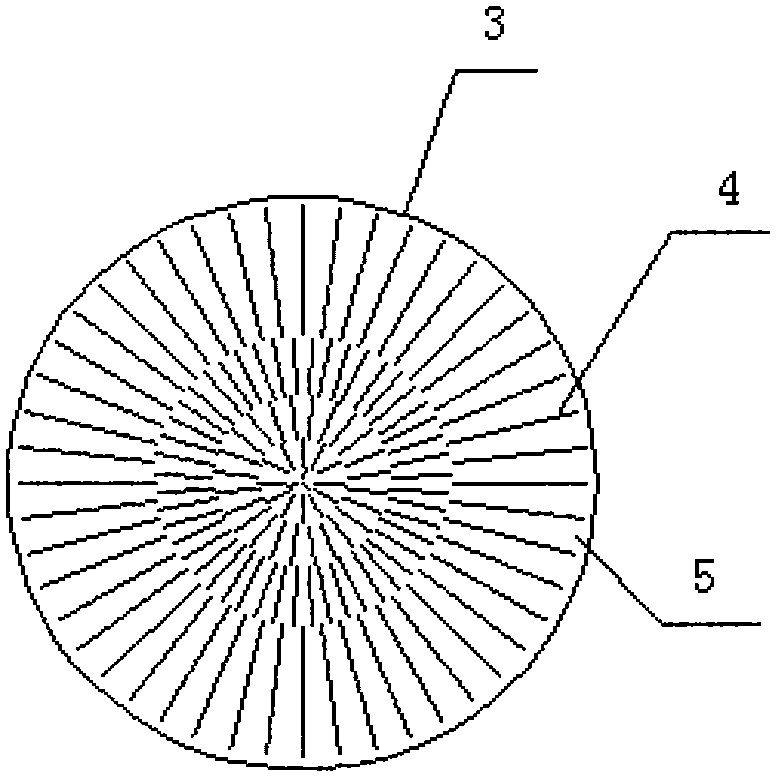

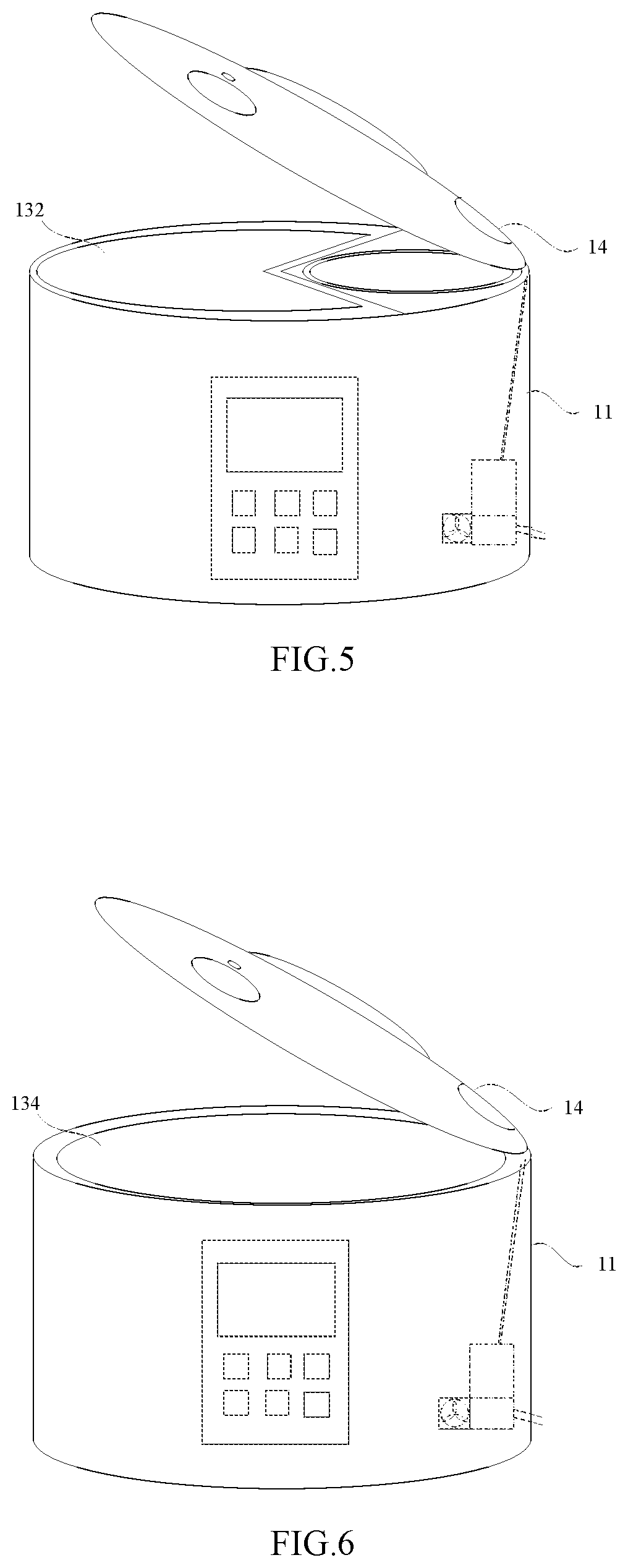

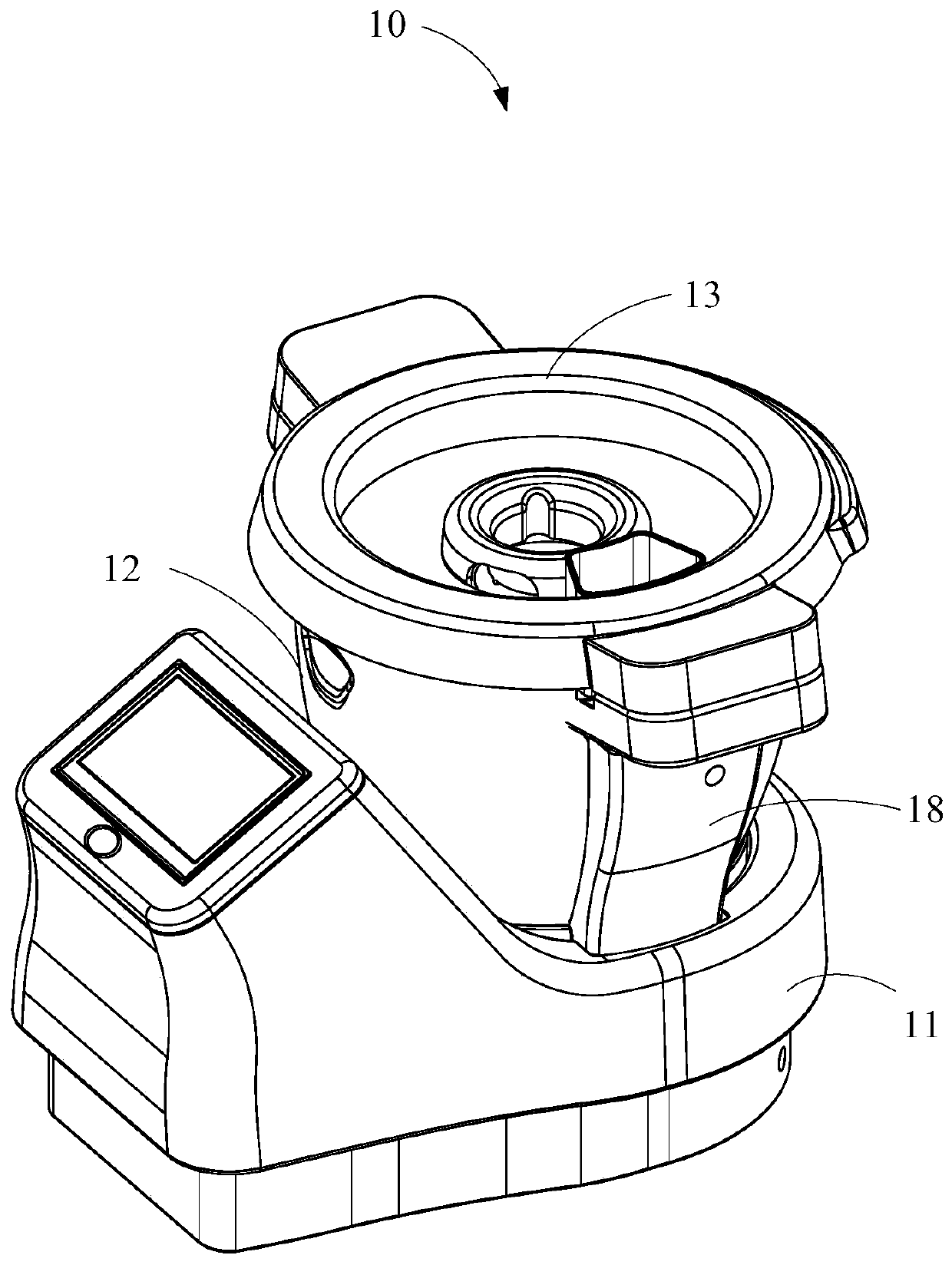

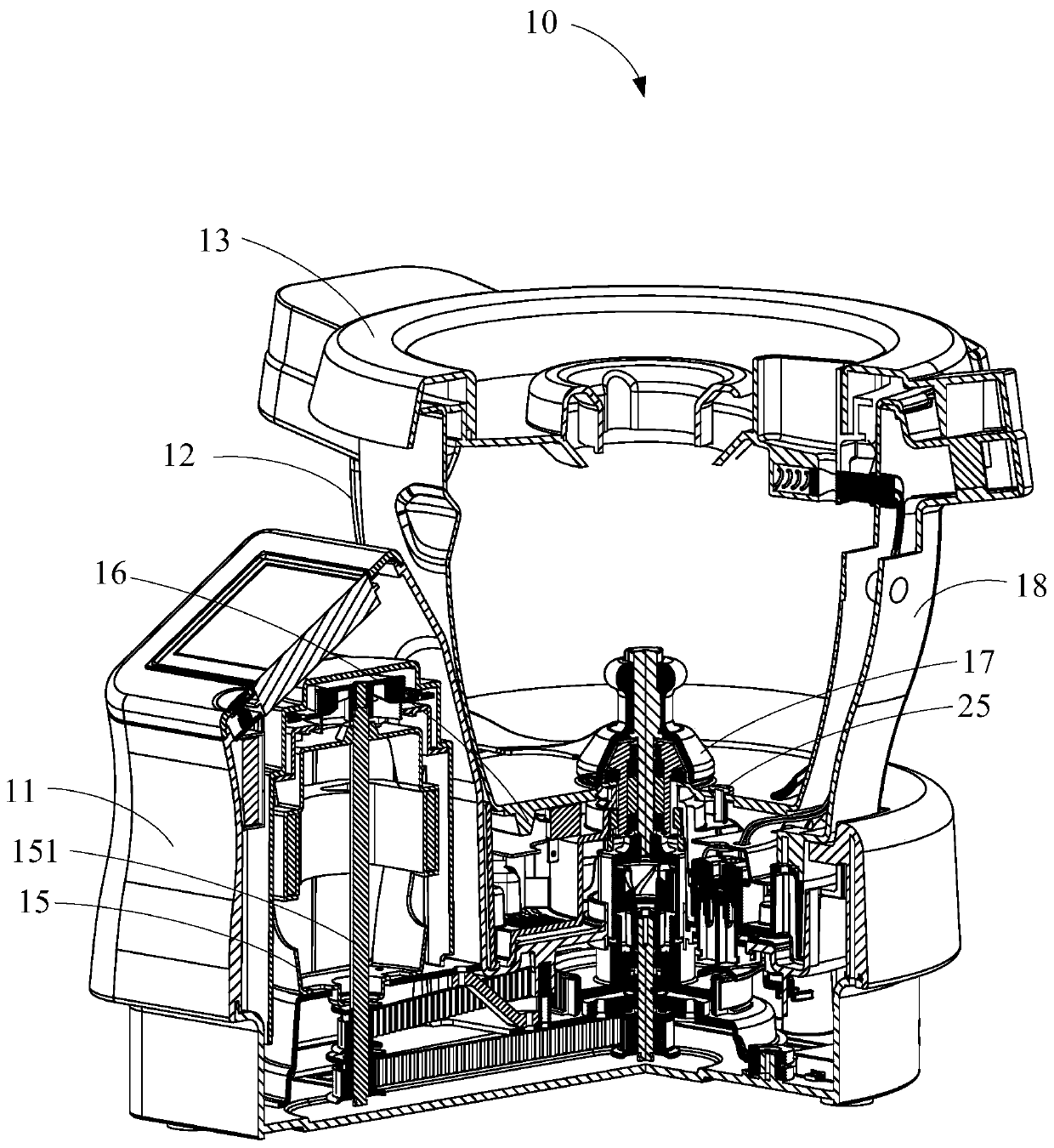

Cooking device with image detection sensor

ActiveUS20180317692A1Avoid problemsCompact structureDomestic stoves or rangesLighting and heating apparatusImage detectionEngineering

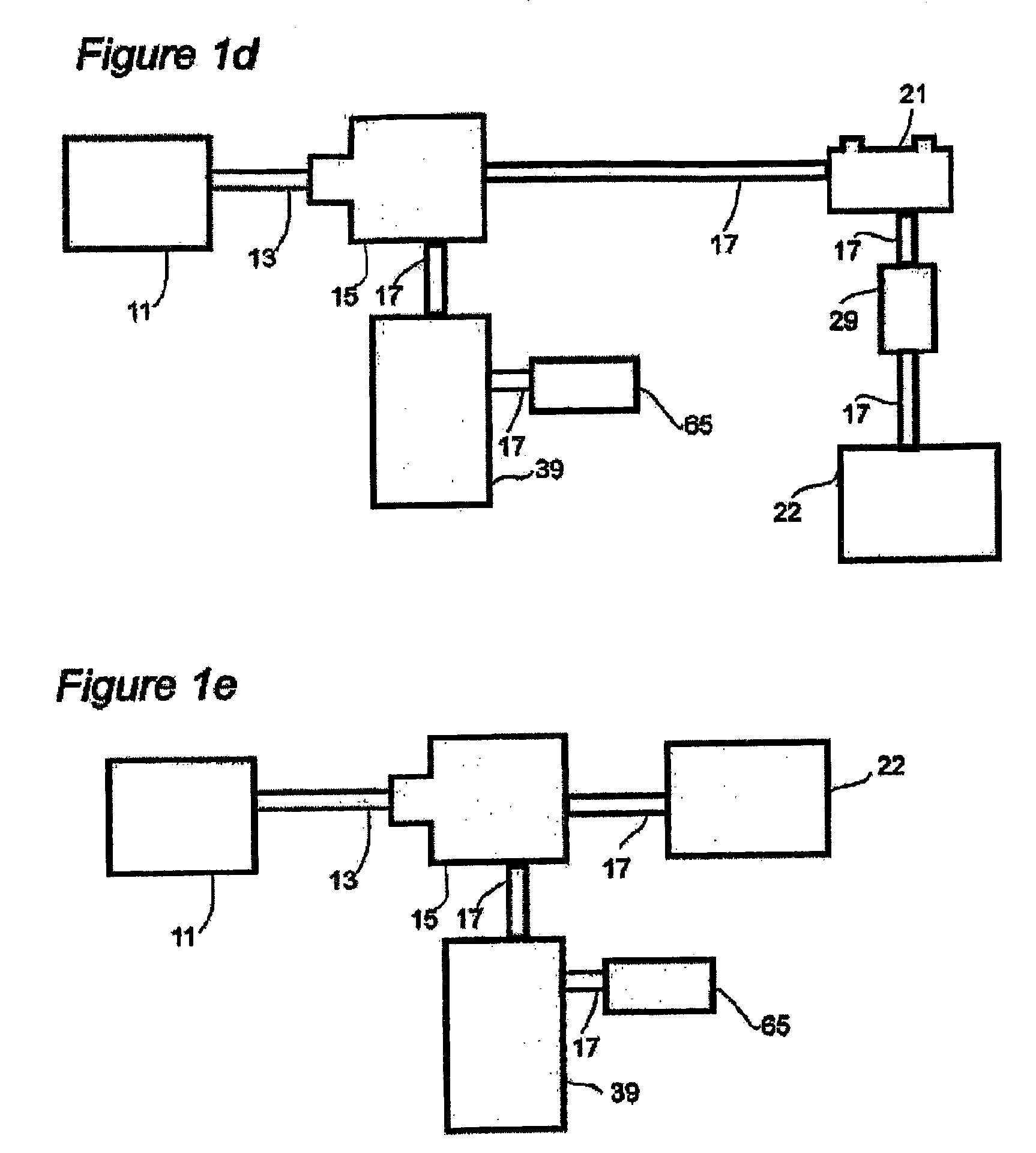

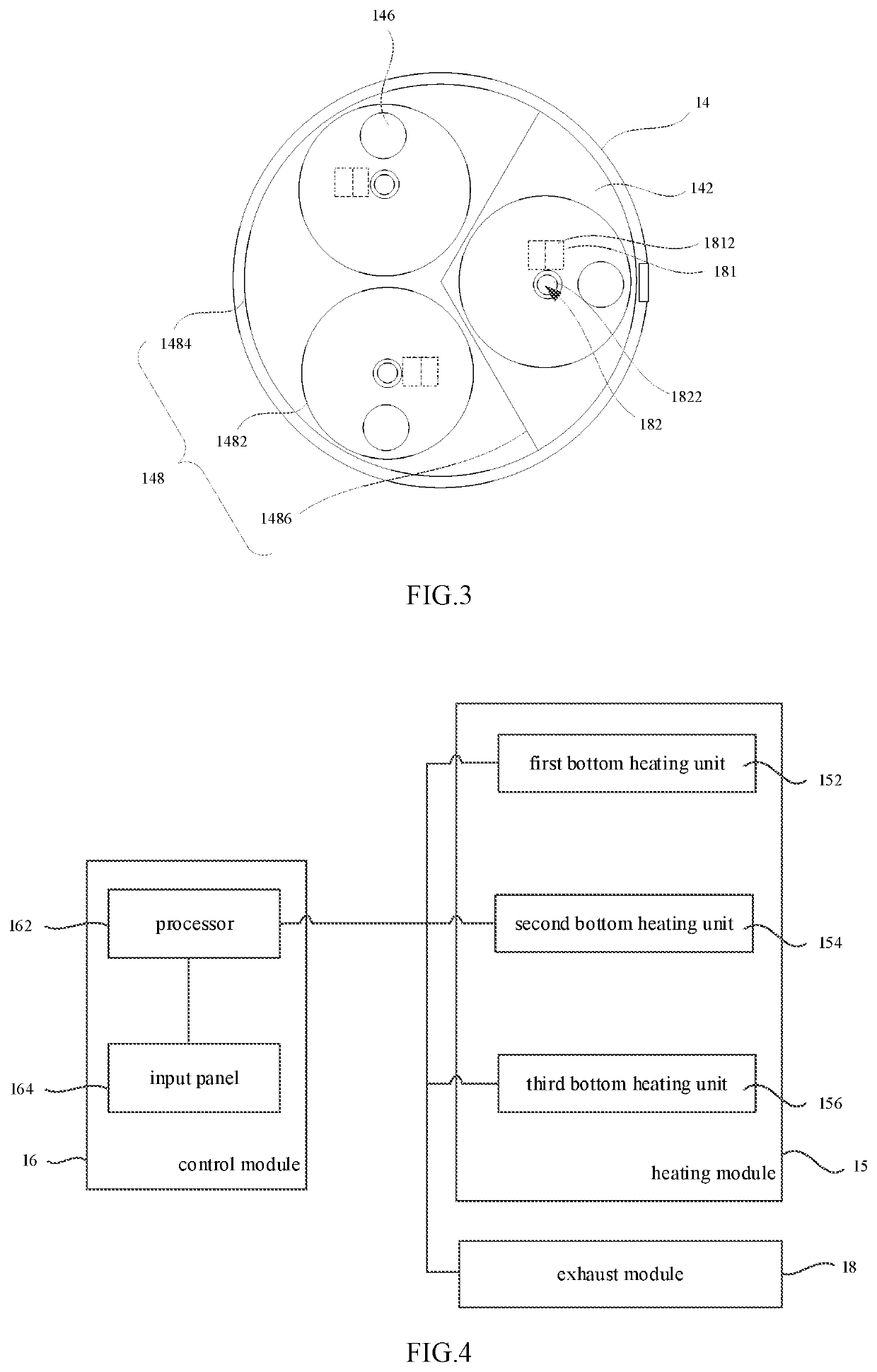

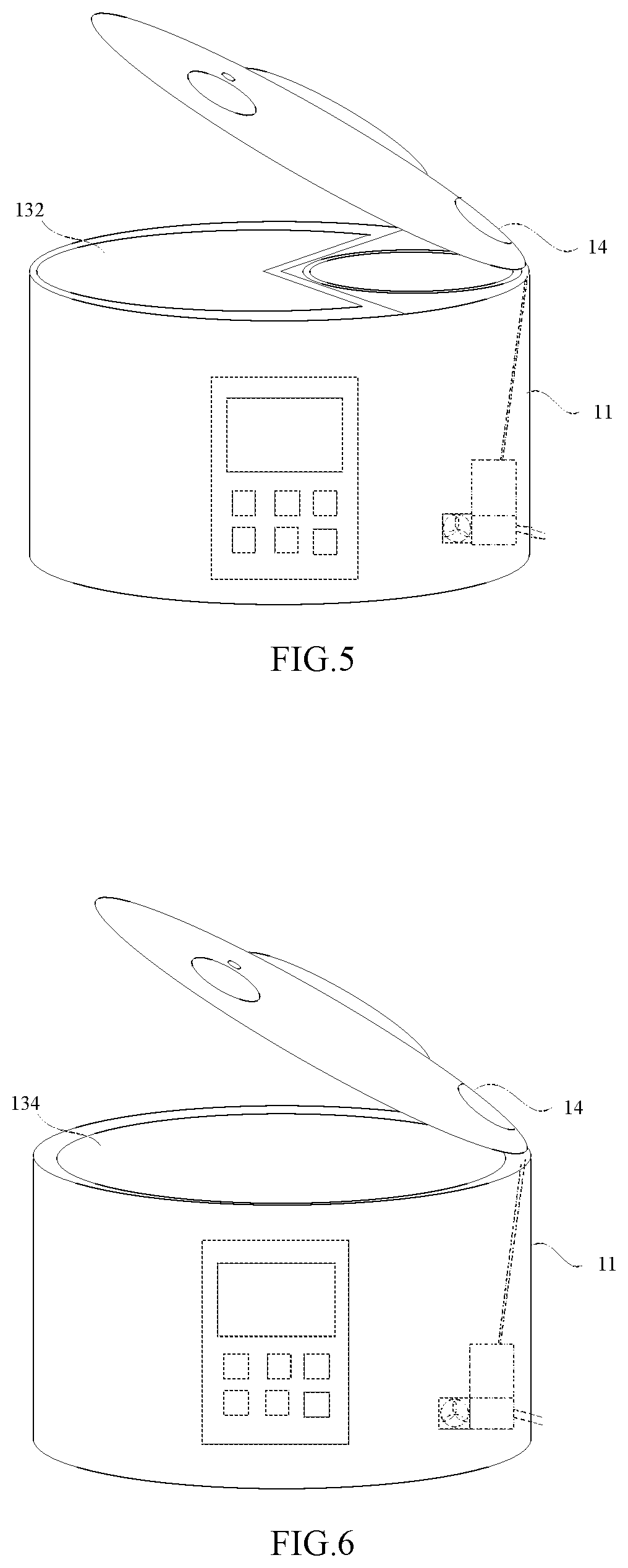

A cooking device includes a base, a housing, a lid, a detection module, a control module and an exhaust module. The detection module includes an image detection sensor arranged on the lid and configured to take an image of a cooking process. The control module includes a processor connected with the detection module and arranged in the base or the housing, and a wireless unit configured to perform information interaction with a portable electronic device to transmit cooking parameters including the image out of the cooking device. The exhaust module includes an air-filled element, an air-extraction element, an inlet passage and an exhaust passage. The inlet passage is disposed on the lid, the air-filled element is disposed on the inlet passage, the air-extraction element is disposed on the exhaust passage and used to exhaust fog or oil fume generated in the at least one inner pot

Owner:SHENZHEN ZEZHI INTPROP CO LTD

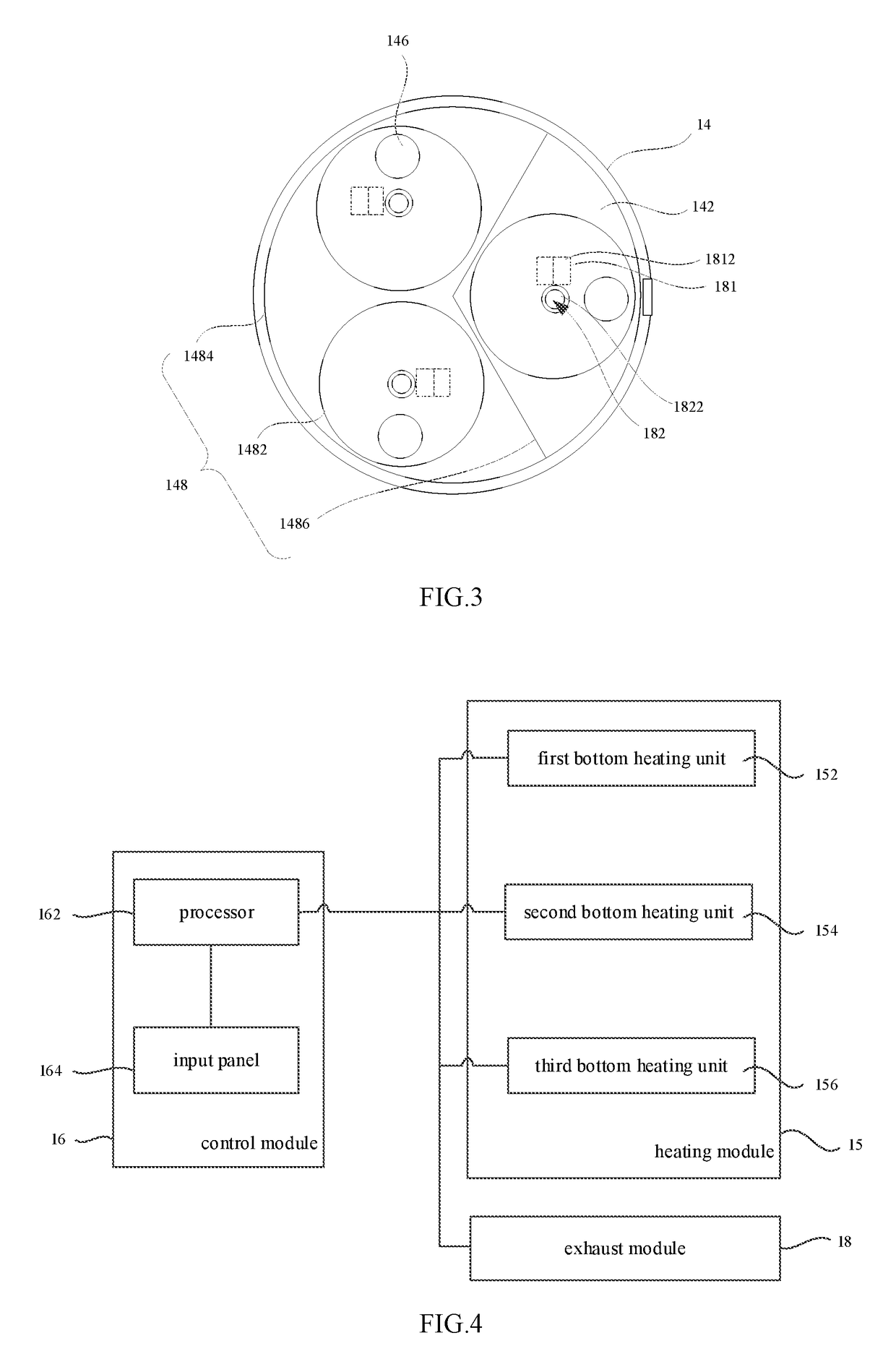

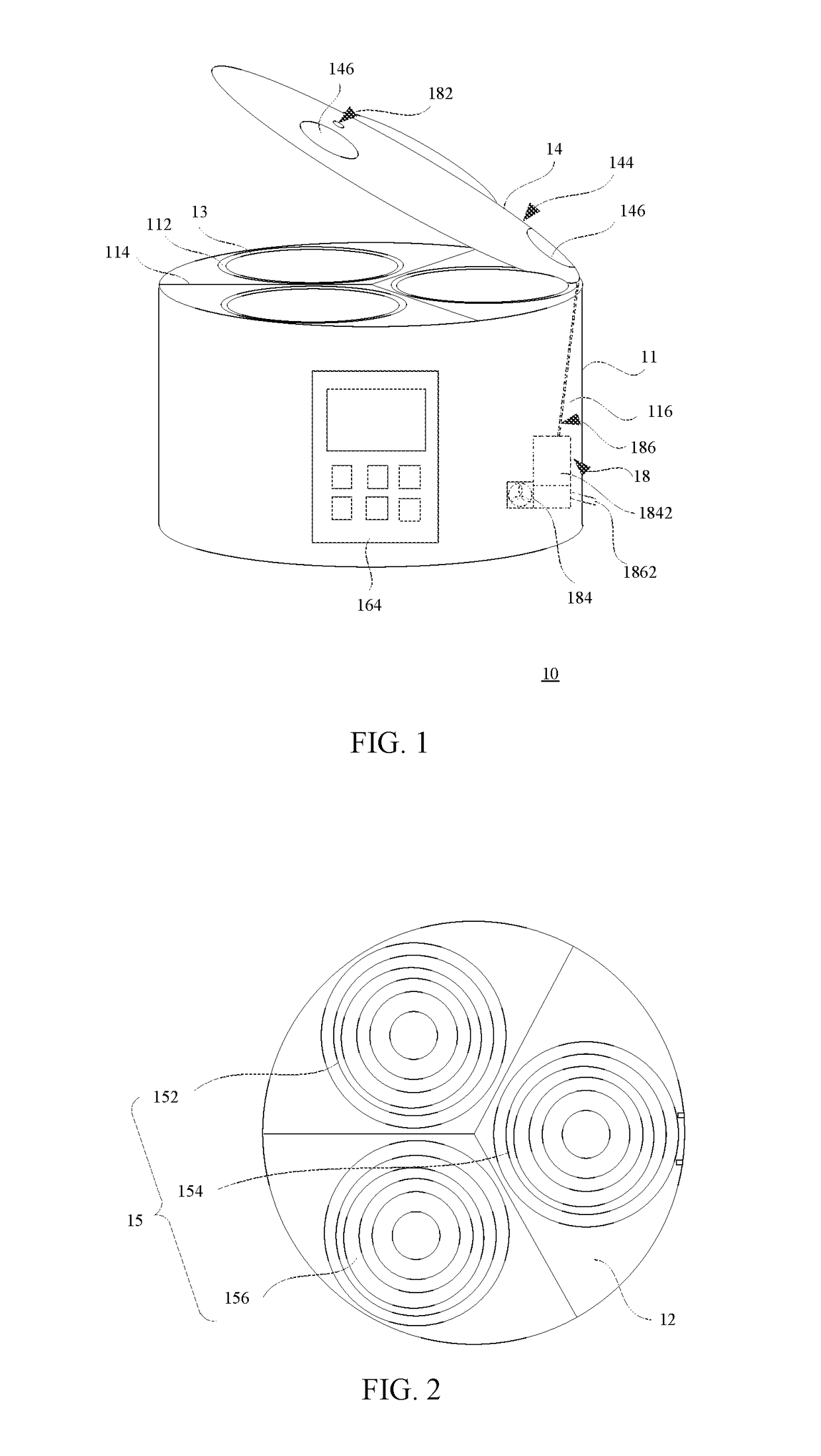

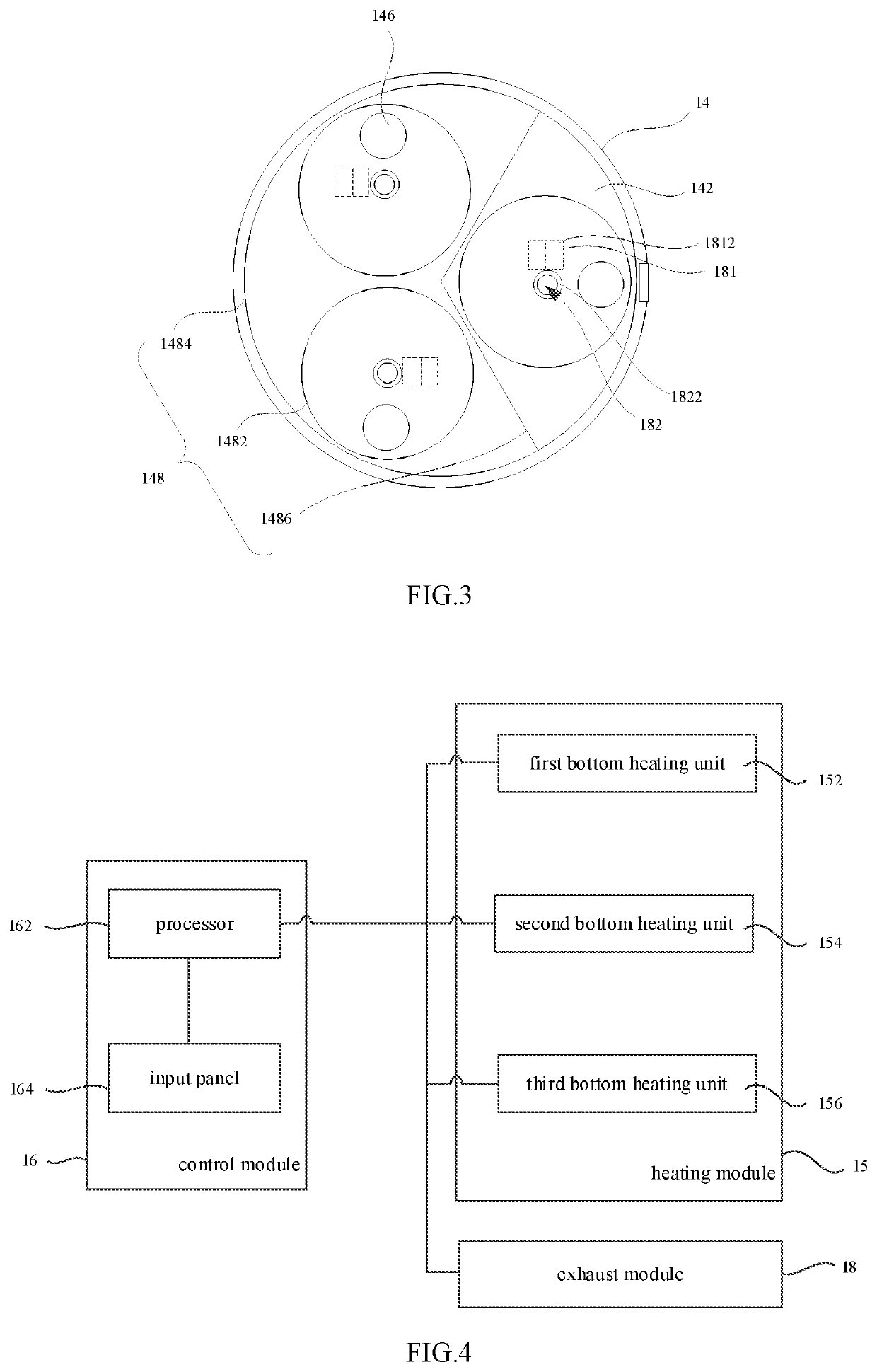

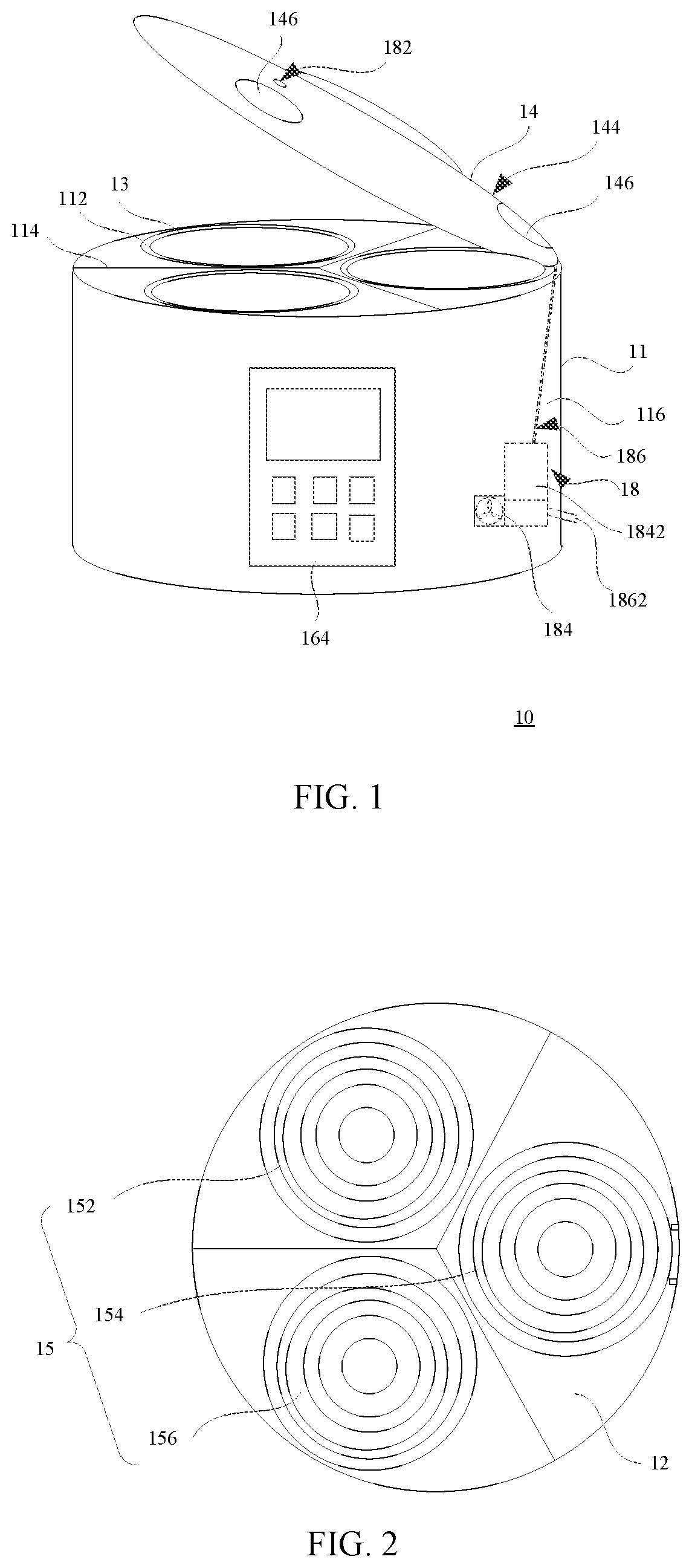

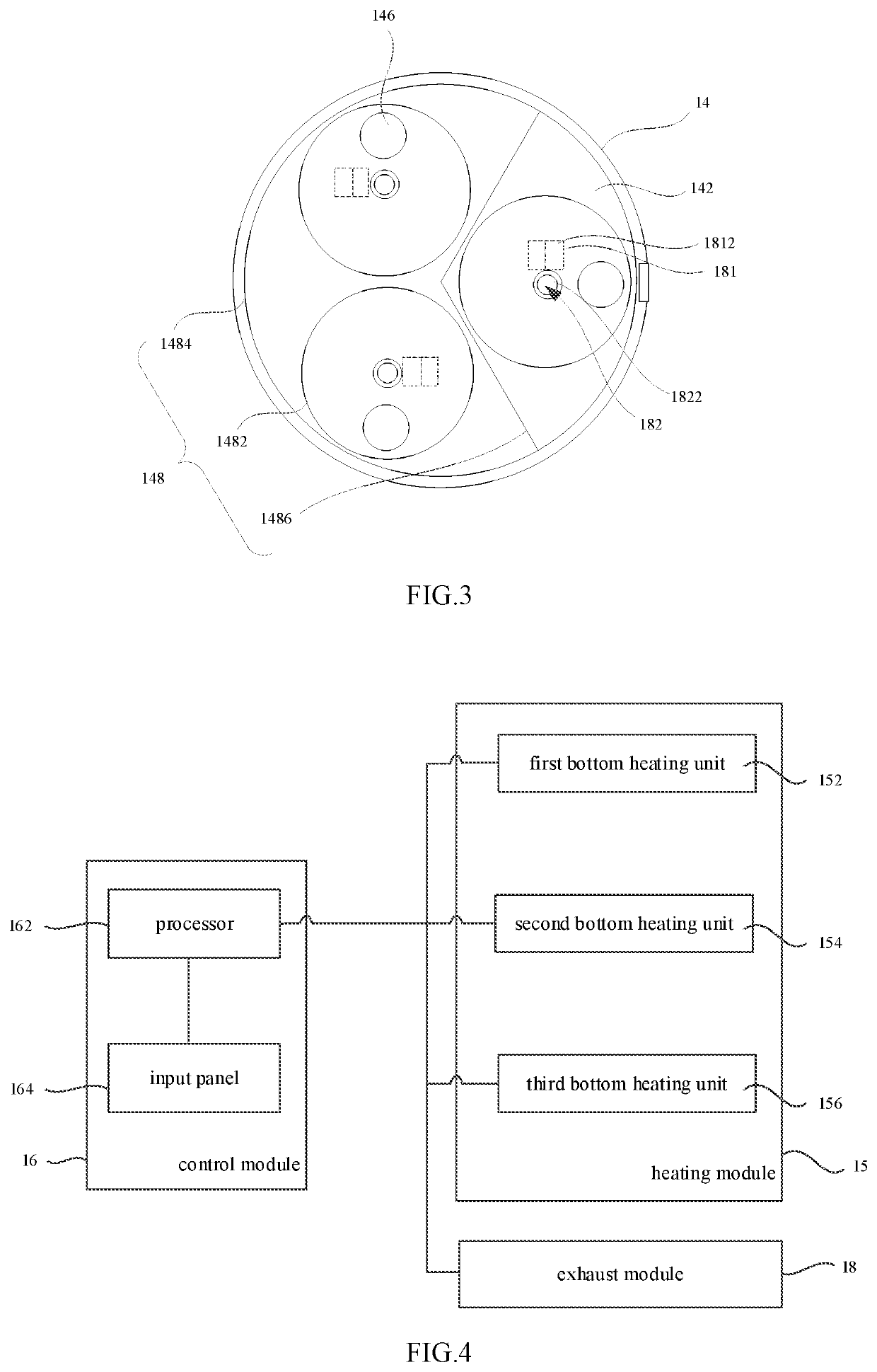

Cooking device with sealing unit

ActiveUS20180317693A1Avoid problemsCompact structureSteam cooking vesselsDeep fat fryersComputer moduleHolding room

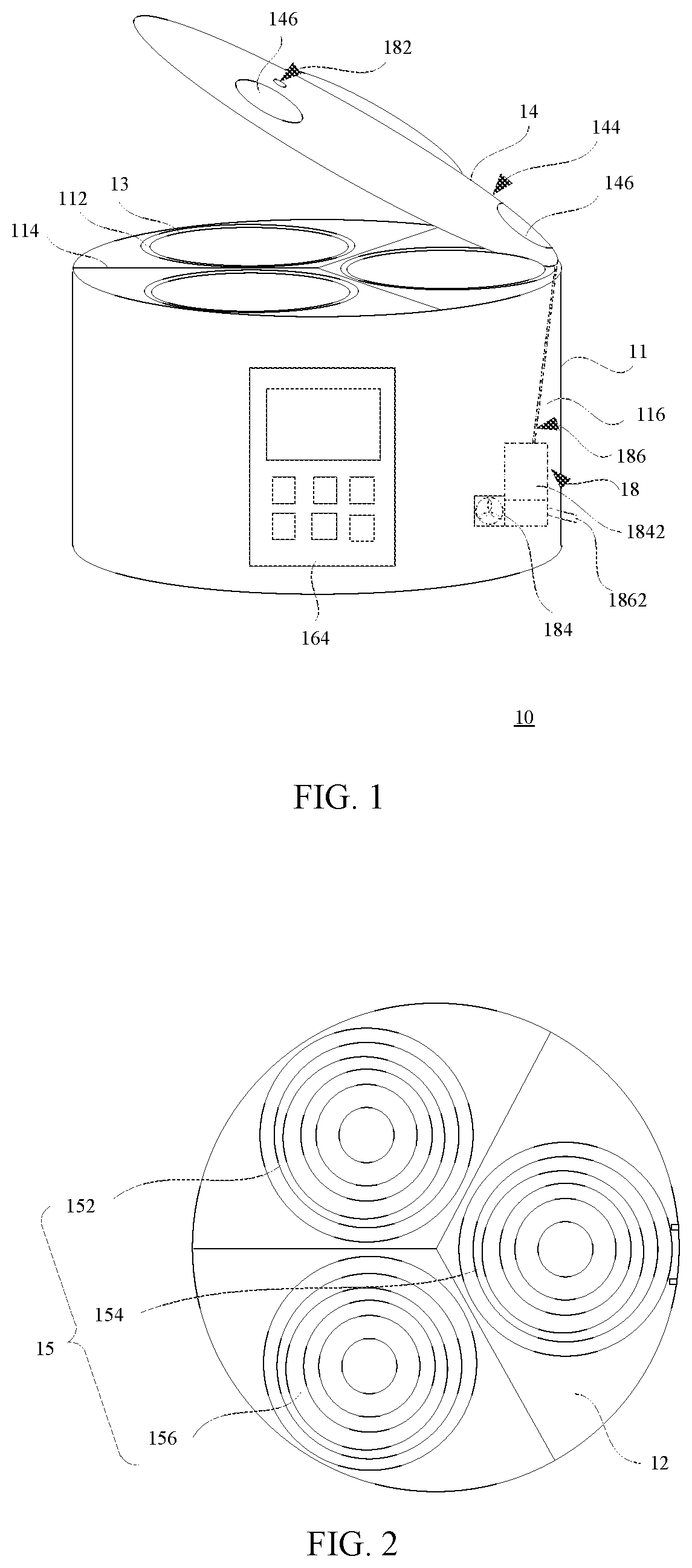

A cooking device includes a base, a housing, a lid, a control module, a heating module and an exhaust module. The heating module includes bottom heating units disposed at different locations inside a storage compartment of the housing. The exhaust module includes an air-filled element, an air-extraction element, an inlet passage, and an exhaust passage used to exhaust fog or oil flume generated in an inner pot(s). An inner surface of the lid is provided with multiple first sealing units, a second sealing unit and a third sealing unit. The third sealing unit is arranged corresponding to an opening of the storage compartment. The second sealing unit is connected with the third sealing unit to divide a region surrounded by the third sealing unit into sub-regions with different sizes. The first sealing units are arranged corresponding to the bottom heating units and in the sub-regions with different amounts.

Owner:SHENZHEN ZEZHI INTPROP CO LTD

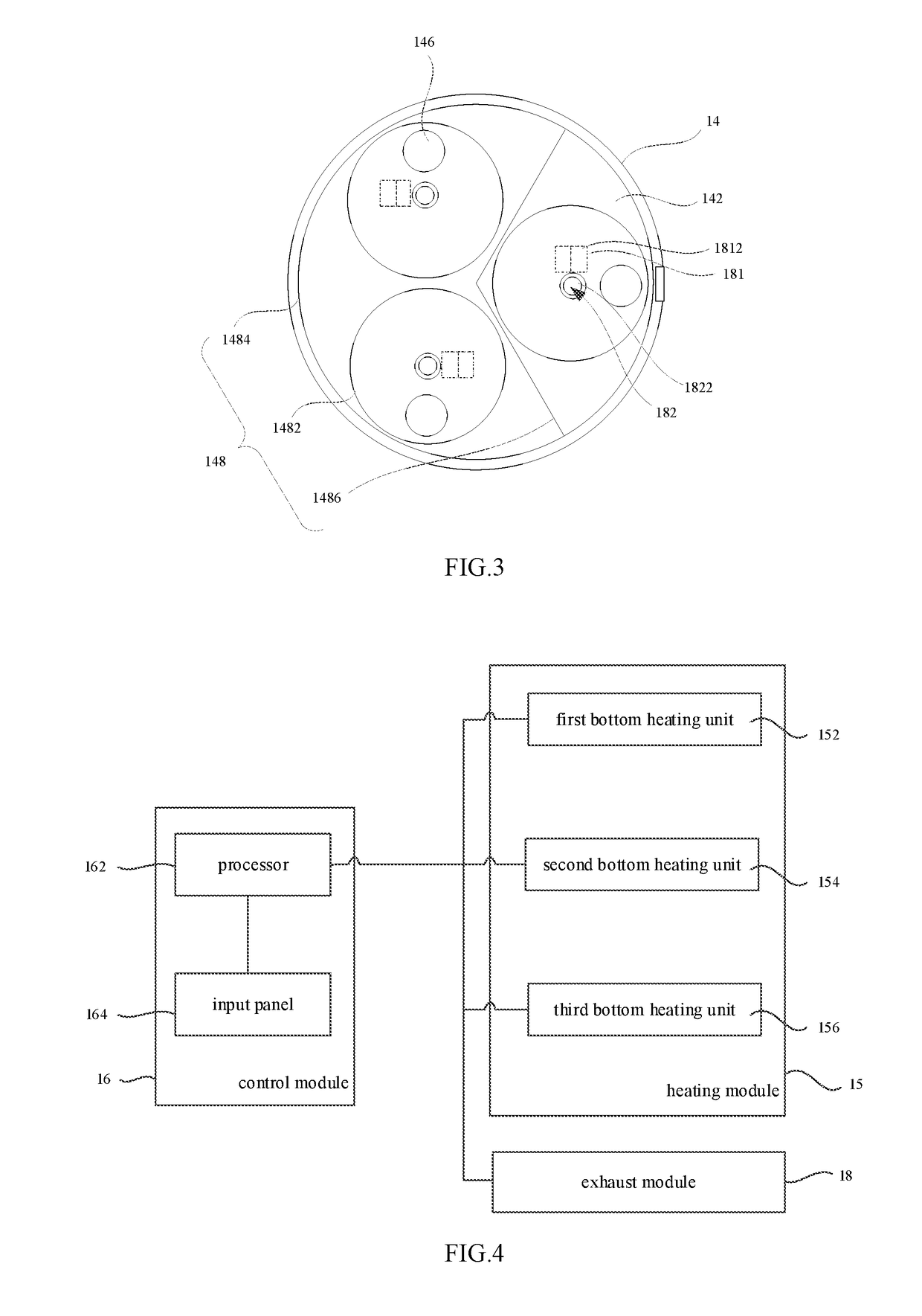

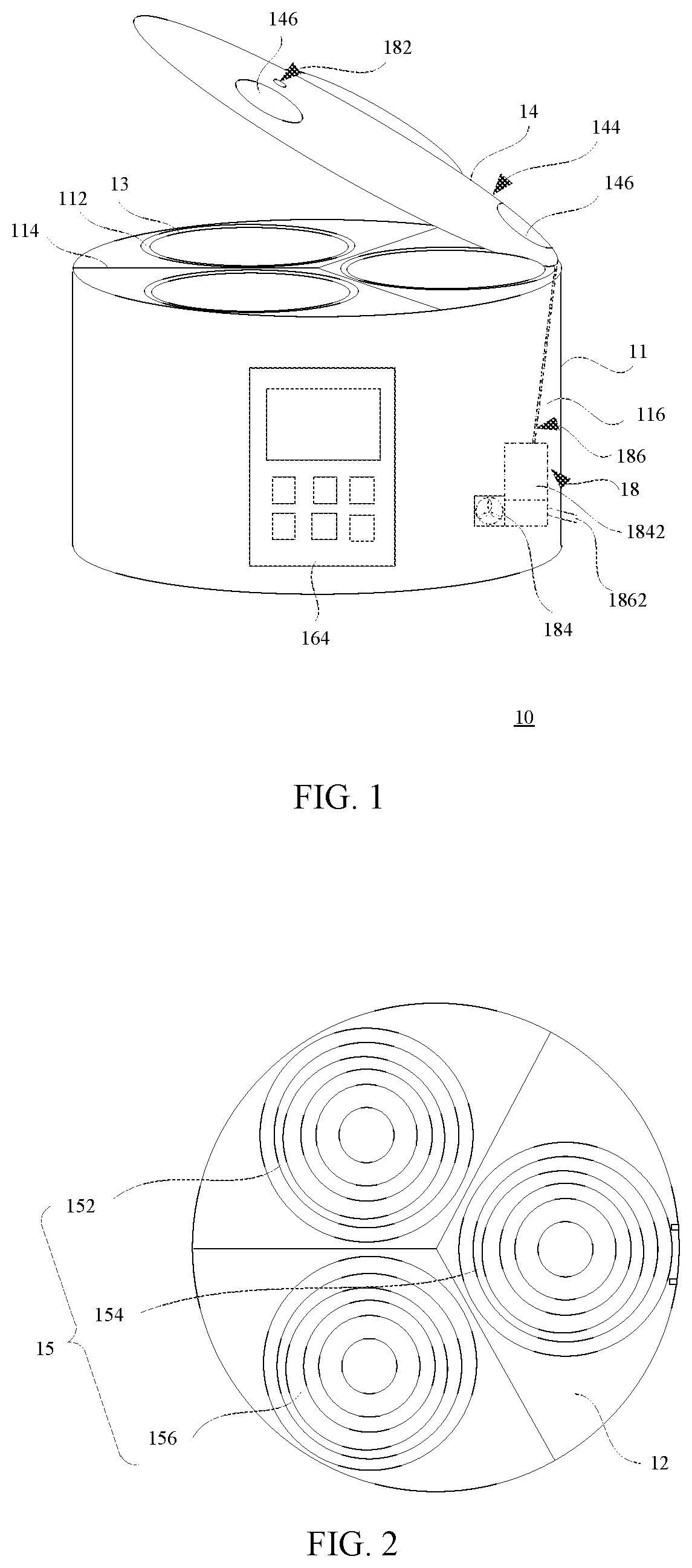

Cooking device with multiple heating units

ActiveUS20180317691A1Avoid fumeSteam cooking vesselsDeep fat fryersElectrical and Electronics engineeringElectrode

A cooking device includes a base, a housing, partition walls, a lid, a control module, an exhaust module, a connecting electrode and a heating module. The exhaust module includes an air-filled element, an air-extraction element, an inlet passage and an exhaust passage. The air-extraction element is used to exhaust fog or oil fume generated in the plurality of inner pots. The connecting electrode is arranged in a middle position of the base. The heating module includes: bottom heating units disposed different locations inside a storage compartment of the housing respectively and connected with the processor individually; second heating units arranged on the partition walls and connected with the connecting electrode by wires inside the partition walls; and third heating units arranged on the inner wall of the housing.

Owner:SHENZHEN ZEZHI INTPROP CO LTD

Electronically Controlled Engine Generator Set

InactiveUS20080238108A1Avoid the needImprove engine efficiencyHybrid vehiclesElectric machinesElectrical impedanceEnergy storage

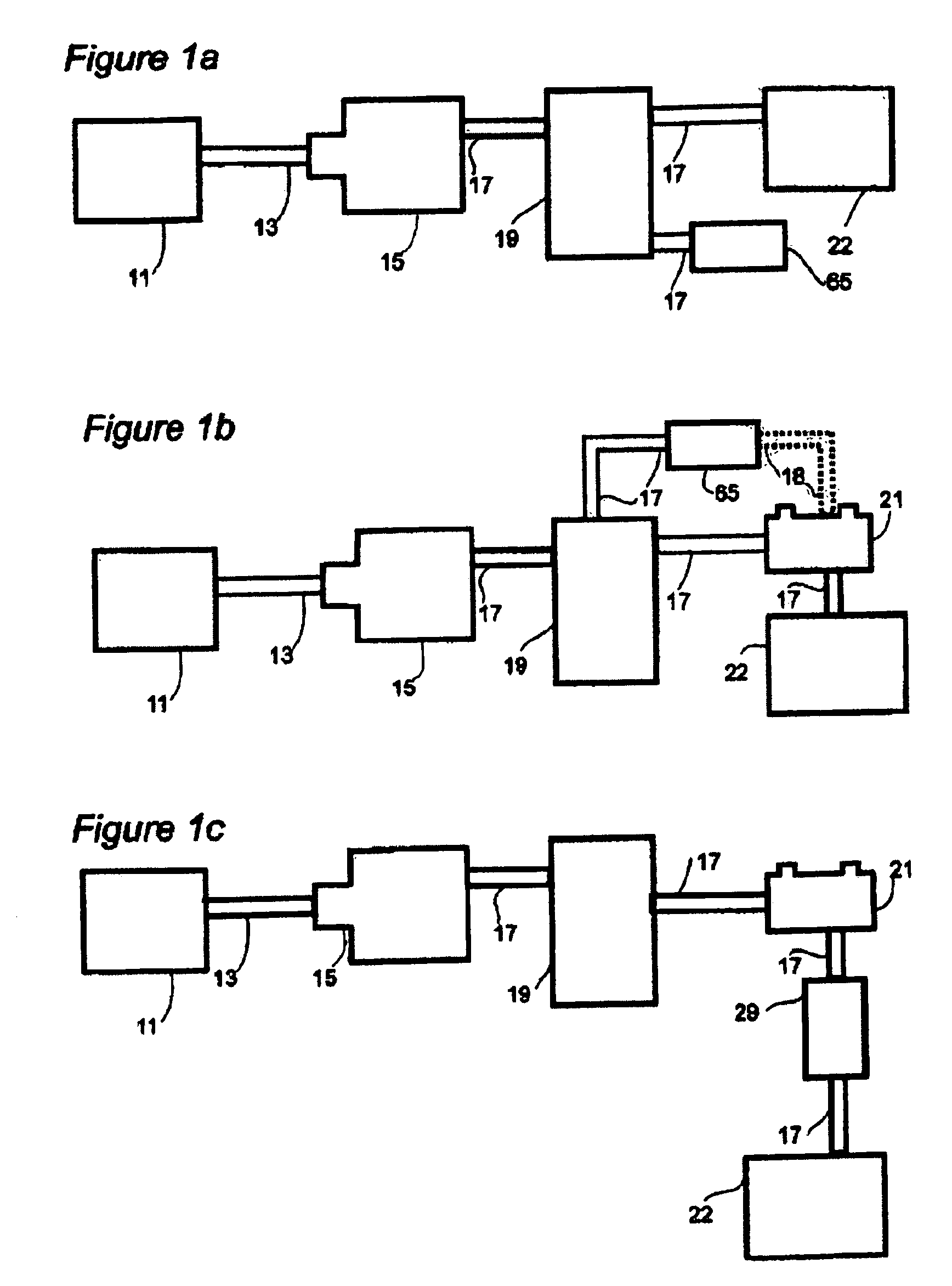

An electronically controlled electrical power generator comprises a generator (15) driven by a heat engine (11), operated by control means (19), and carrying an electrical load (22). Operation of the heat engine (11) is at wide open throttle. Control over engine operation and electrical output of the generator (15) is achieved by electronically manipulating the electric load (22), and / or adjusting excitation levels at the generator's magnetic fields, so as to change engine / generator equilibrium speed. In a beneficial embodiment, the generator (15) is powered by an energy storage unit (21), to temporarily act as a motor and rotate the engine (11) when starting, and during power absorbing strokes. A method for controlling an unthrottled engine (11) including varying the gear ratio of a transmission connected between the mechanical output of the engine (11) and a mechanical load (22), to provide a torque load to the engine (11) to cause the engine (11) to move to an equilibrium speed at which its power output substantially meets a power output requirement. In a second embodiment, variance in the impedance of an AC generator (15) connected to the engine (11) provide a torque load to the engine (11) to control its equilibrium speed.

Owner:BOREALIS TECH LTD

Cooking device with image detection sensor

ActiveUS10694882B2Avoid fumeDomestic stoves or rangesLighting and heating apparatusImage detectionElectric devices

A cooking device includes a base, a housing, a lid, a detection module, a control module and an exhaust module. The detection module includes an image detection sensor arranged on the lid and configured to take an image of a cooking process. The control module includes a processor connected with the detection module and arranged in the base or the housing, and a wireless unit configured to perform information interaction with a portable electronic device to transmit cooking parameters including the image out of the cooking device. The exhaust module includes an air-filled element, an air-extraction element, an inlet passage and an exhaust passage. The inlet passage is disposed on the lid, the air-filled element is disposed on the inlet passage, the air-extraction element is disposed on the exhaust passage and used to exhaust fog or oil fume generated in at least one inner pot.

Owner:SHENZHEN ZEZHI INTPROP CO LTD

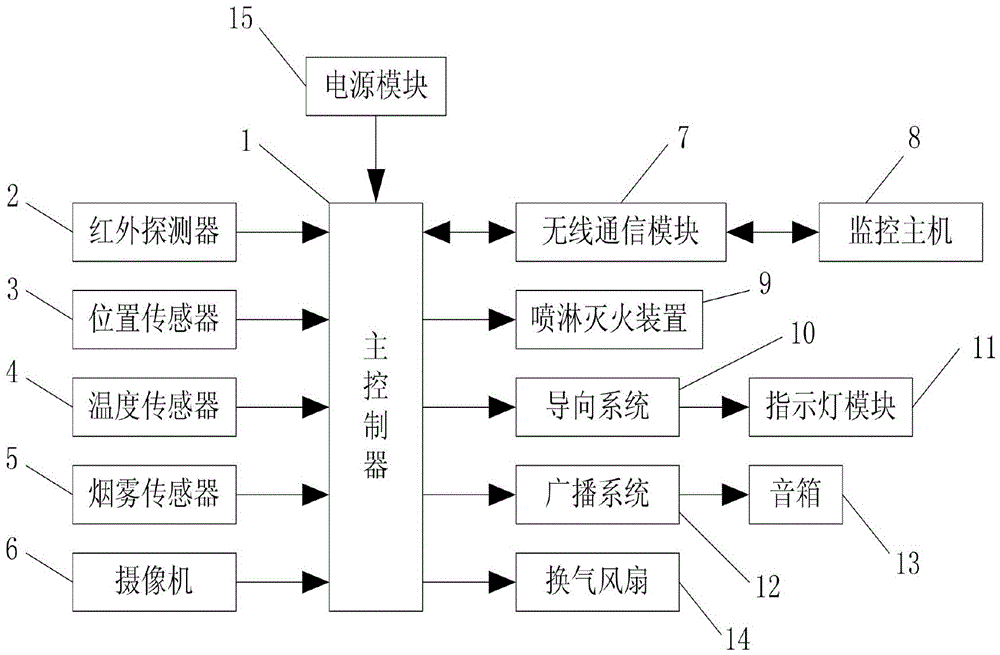

Fire alarm control system

InactiveCN104658162ASimple structureReasonable designSignalling system detailsFire rescueScavengerEngineering

The invention discloses a fire alarm control system which comprises a master controller, a wireless communication module and a power module, wherein the wireless communication module is connected with the master controller; the input end of the master controller is connected with a signal acquisition module and a camera; the output end of the master controller is connected with a water spray suppression device, a guiding system, a broadcasting system and a scavenger fan; the guiding system is connected with an indicator lamp module; the broadcasting system is connected with a loudspeaker box; the wireless communication module is connected with a monitoring host; the signal acquisition module, the camera, the guiding system and the broadcasting system are arranged at the stairway in the building; the water spray suppression device is arranged at the top in the building; the scavenger fan is arranged on the wall and communicated with the outdoor; the monitoring host is arranged in the residential area monitor room. The fire alarm control system can be used for indicating the safe escape direction and displacing the dense smoke outdoors through the scavenger fan while reducing the fire by the water spray suppression device, and has the advantages of high control reliability, high working stability, long service life, strong practicability, good using effect and convenience in popularization and use.

Owner:XIAN ALL SAFE SCI & TECH

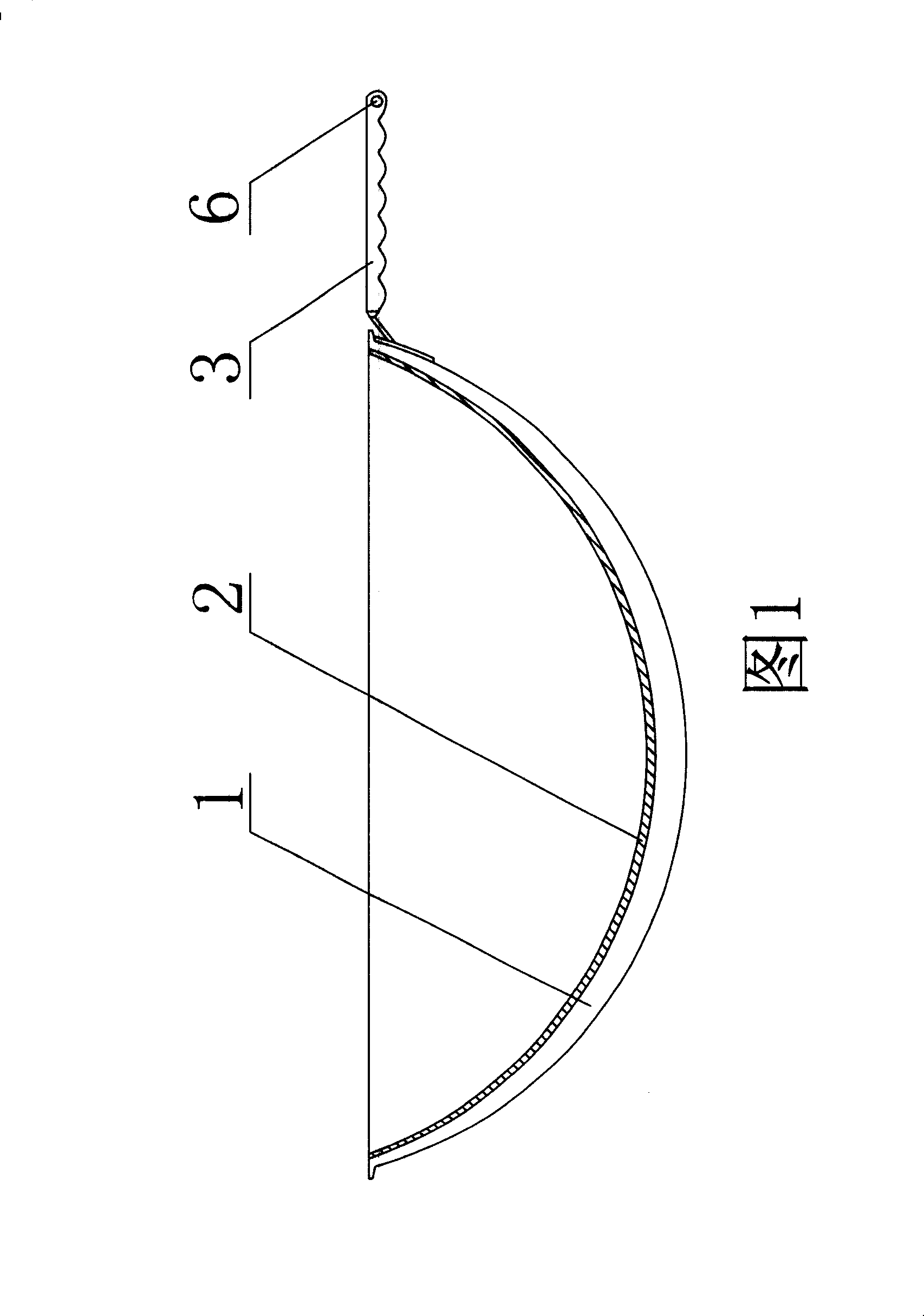

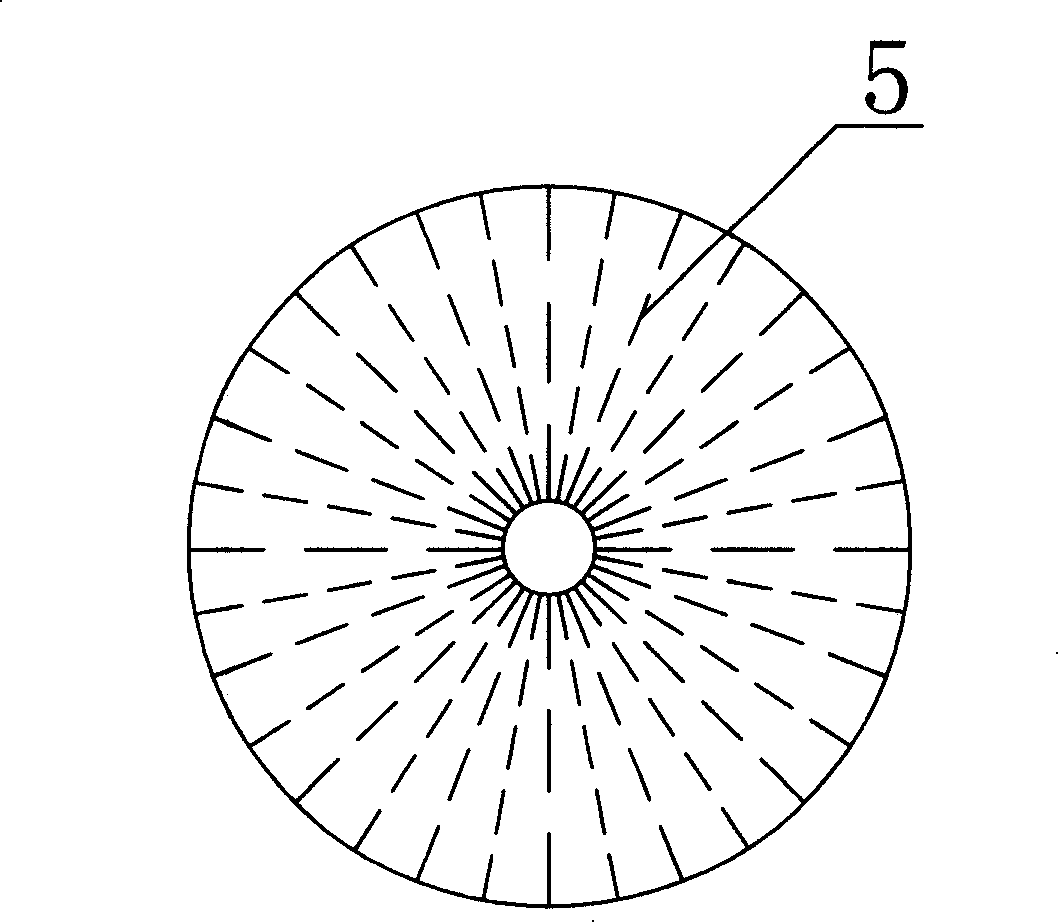

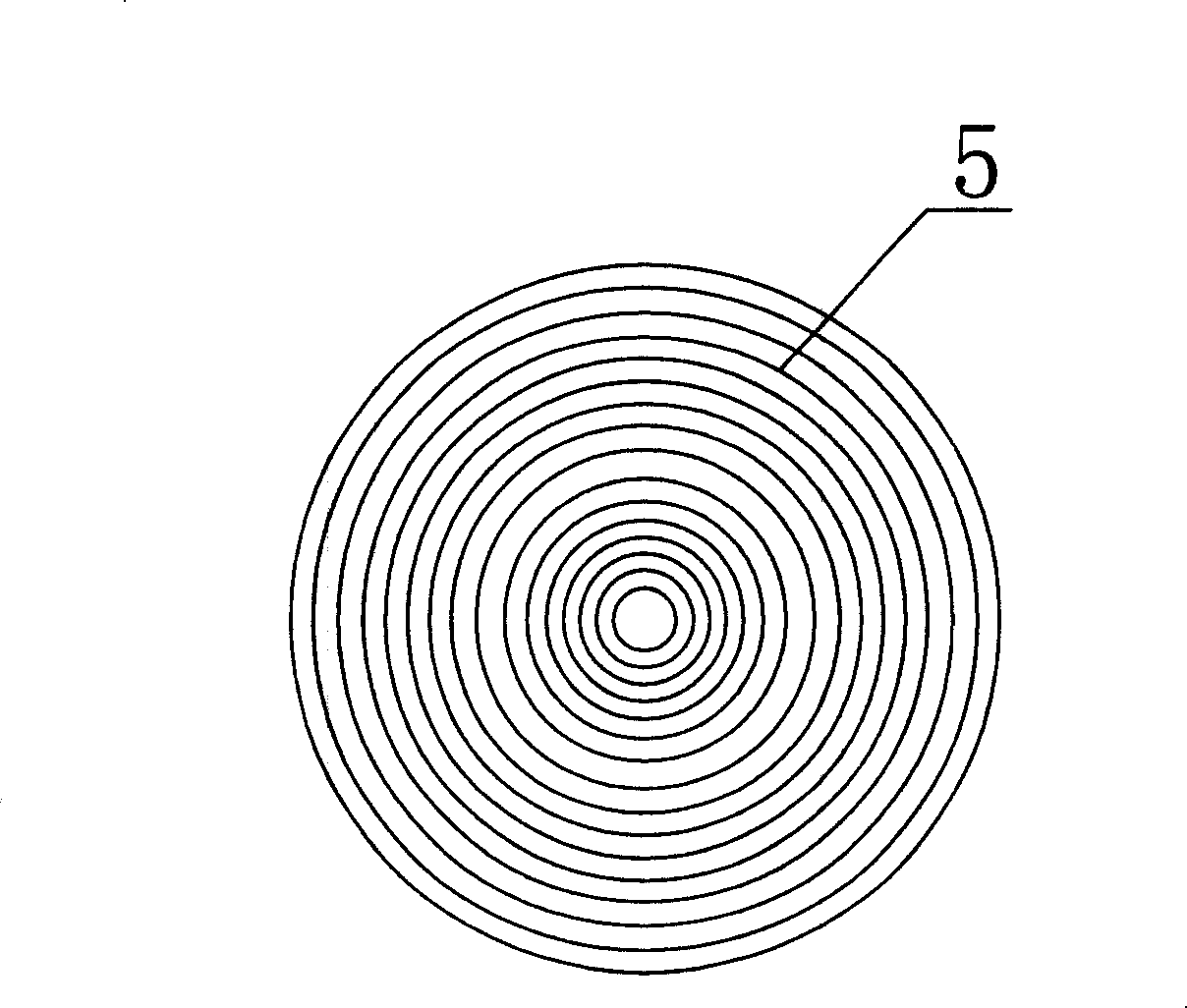

Fume-less cooker

InactiveCN101234001AIncrease the surface heating areaIncrease profitCooking-vessel materialsFrying pansConvex structureMetallurgy

The invention discloses an oil-free and smoke-free pan which comprises a pan body and a uniform heating layer of which thermal conductivity is lower than the thermal conductivity of the pan body. The uniform heating layer is arranged on the inner surface of the pan body. The invention adopts an aluminium alloy or magnesium alloy pan body with relatively high thermal conductivity, thus realizing a rapid heating. Furthermore, a purple sand ceramic uniform heating layer with relatively low thermal conductivity is sintered or a stainless steel uniform heating layer is compounded on the inner surface of the pan body to dissipate local high temperature on the pan body to the whole uniform heating layer, which ensures that no local high temperature, oil and smoke is produced in the pan, thus saving energy. A plurality of small convex structures are arranged on the uniform heating layer. Air is in a groove between the convex structures and the air is expanded after being heat, which results in the separation of food and the pan body to have physically non-stick effect. Compared with original immersion coating, the physical non-stick structure has better non-stick effect. A helical structure is adopted on the outer surface of the pan body, thereby increasing outer surface area of the pan body and improving energy utilization rate.

Owner:胡金高

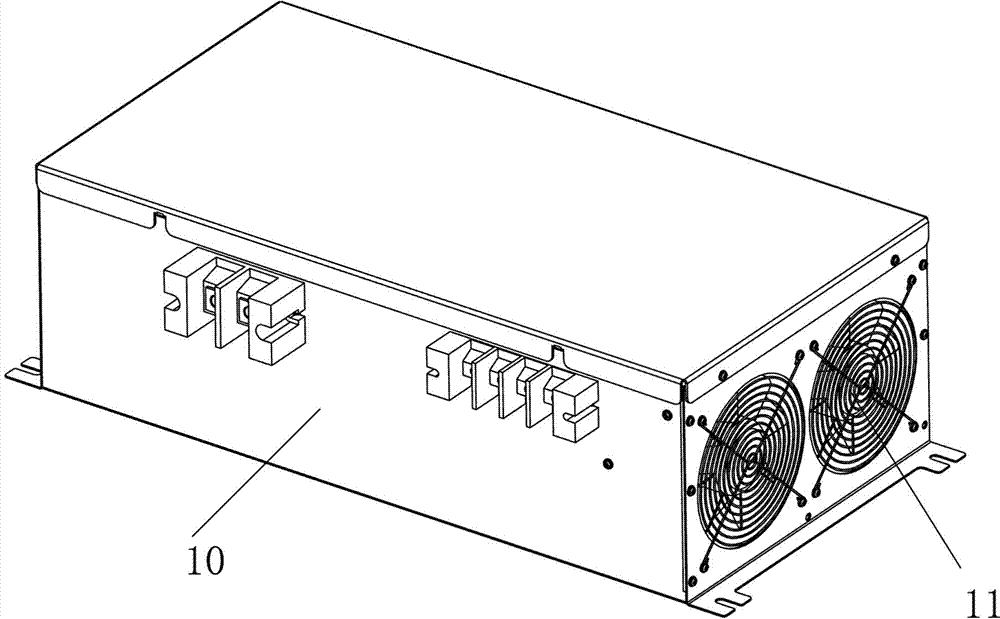

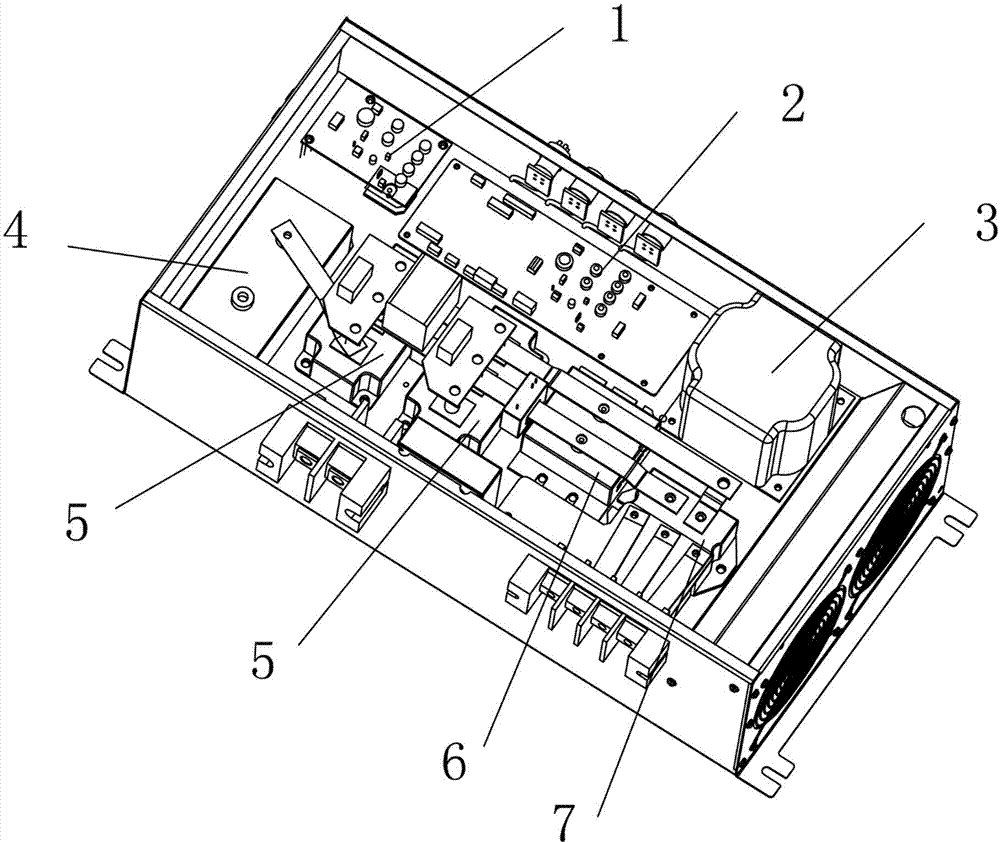

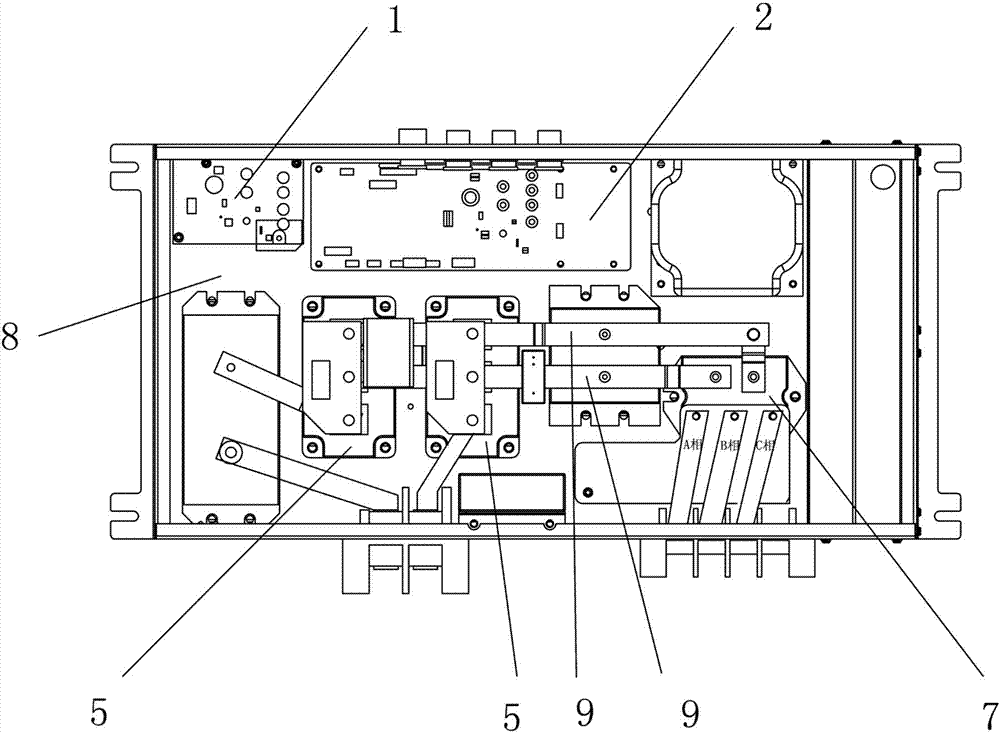

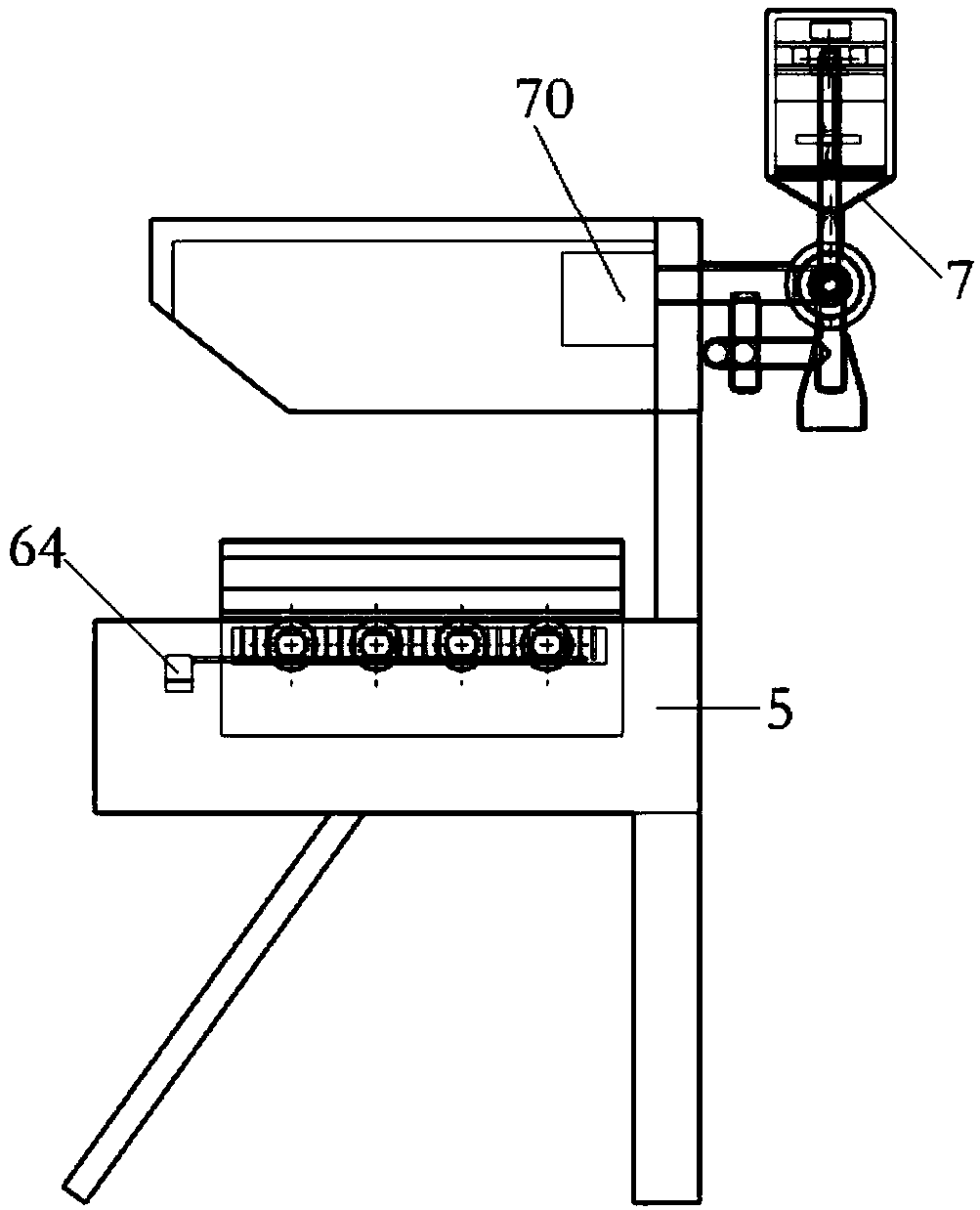

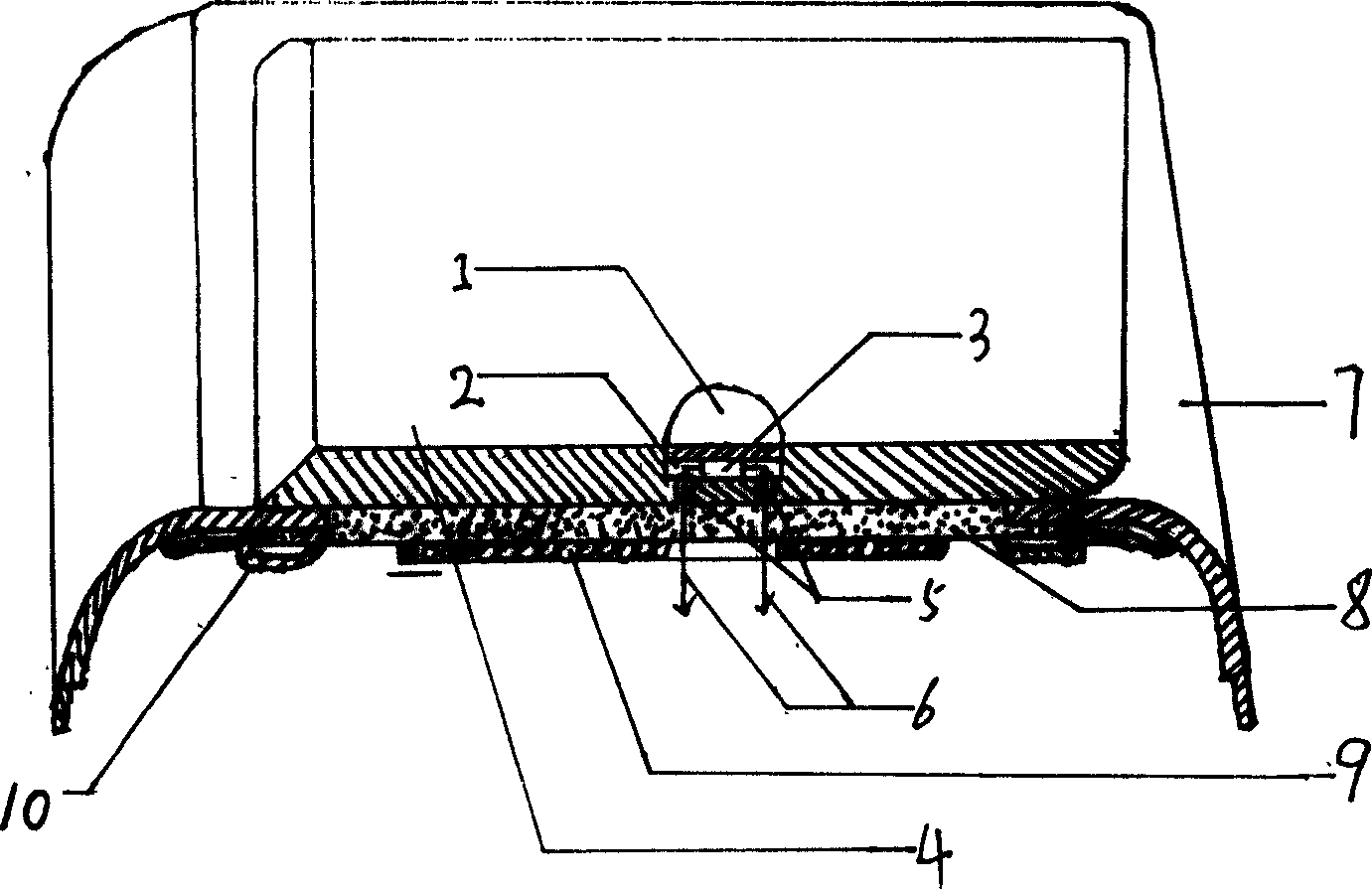

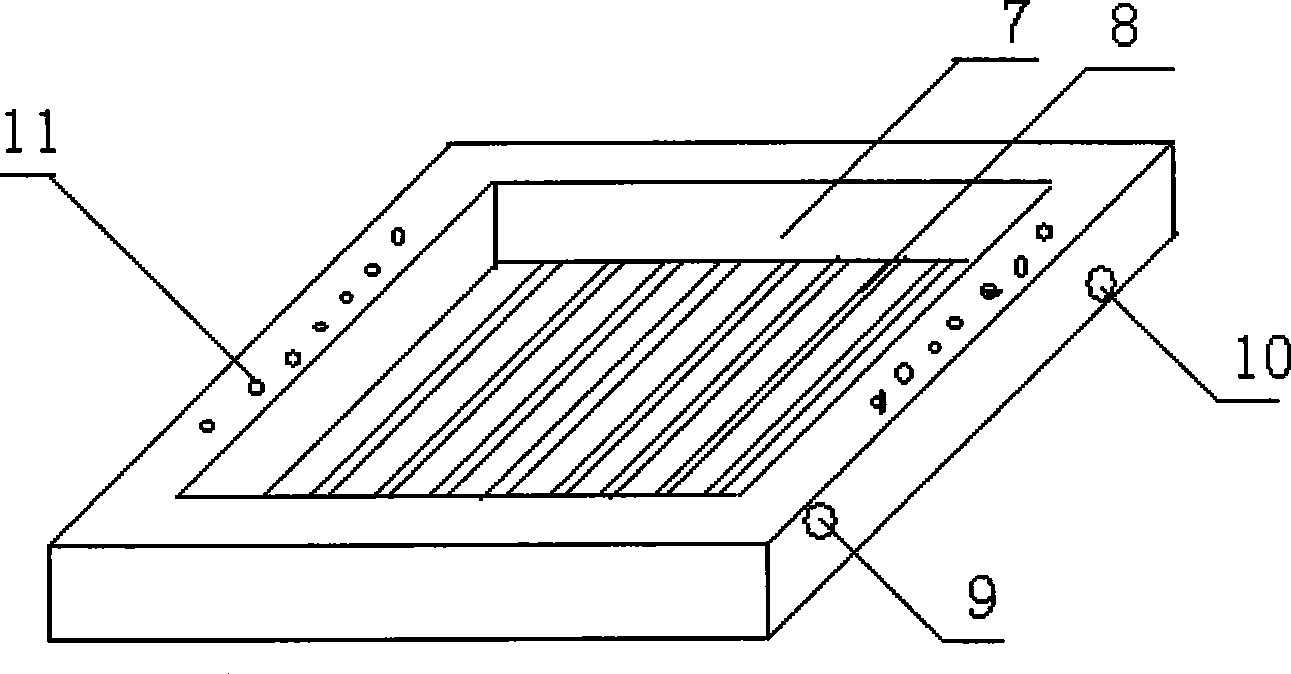

Structure of machine core of commercial induction cooker

InactiveCN103582195AReduce distractionsImprove performanceDomestic stoves or rangesLighting and heating apparatusForeign matterControl circuit

The invention discloses a structure of a machine core of a commercial induction cooker. The structure of the machine core of the commercial induction cooker comprises a machine box and a coil panel, wherein the machine box is flat, a control circuit board, a circuit board radiator, a direct current fan and a turbofan are distributed on a base plate of the machine box, air inlets under the corresponding direct current fan and the turbofan are formed in the base plate, an oil smoke filtering net is arranged on each air inlet, an air feeding port of the turbofan faces the circuit board radiator, and the coil panel is located above the direct current fan. The structure of the machine core of the commercial induction cooker adopts a novel lower absorption side exhaust type machine box heat dissipation structure, the inner structure is more reasonable and compact, the oil smoke filtering nets are arranged on the air inlets of the machine box and can filter out large-particle impurities, oil smoke prevention of the machine core is facilitated, and the influence on circuit devices of products from foreign matter such as cockroaches and insects under the environment of a commercial kitchen is effectively prevented.

Owner:FOSHAN SHUNDE HIGHWAY ELECTRONICS

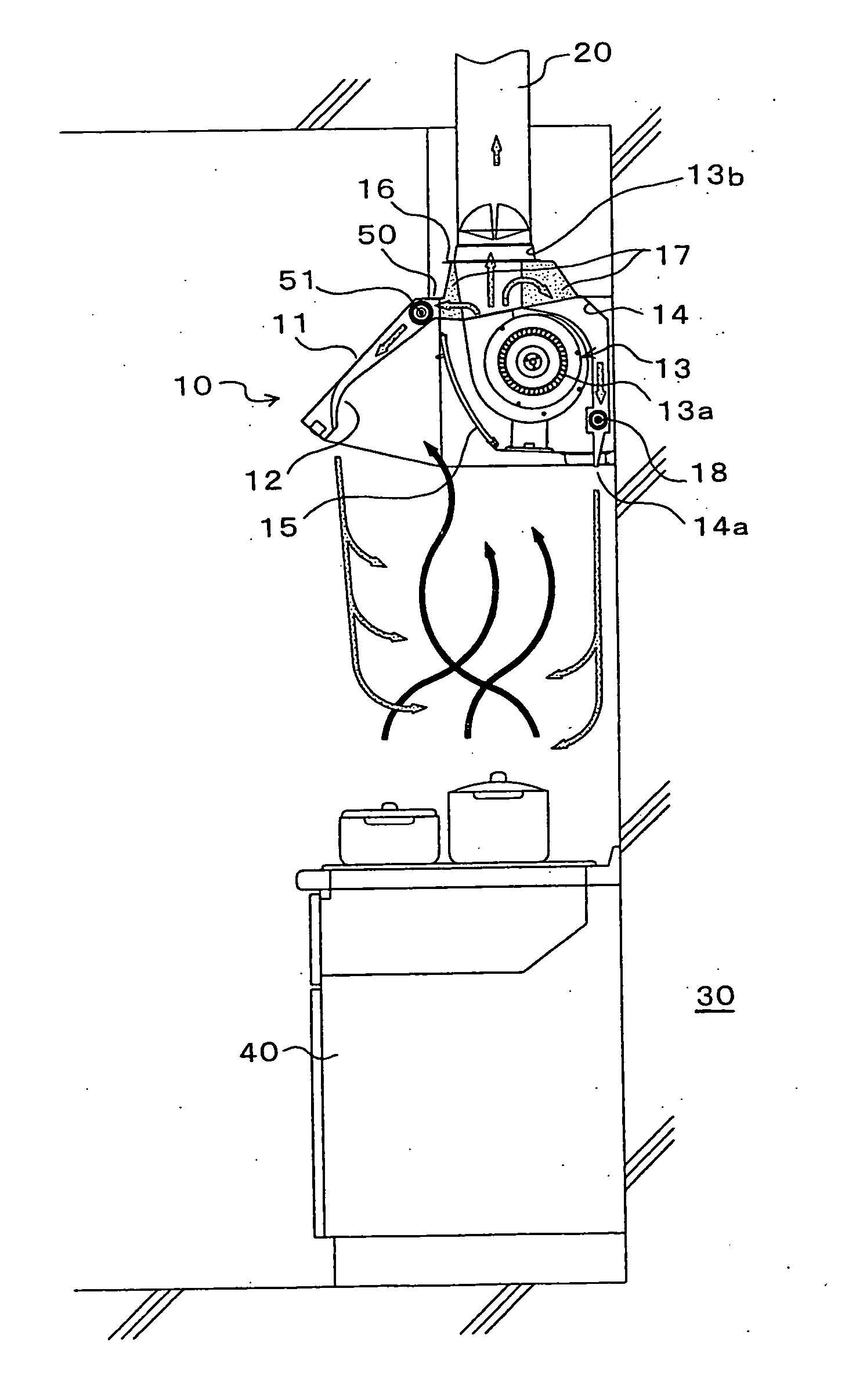

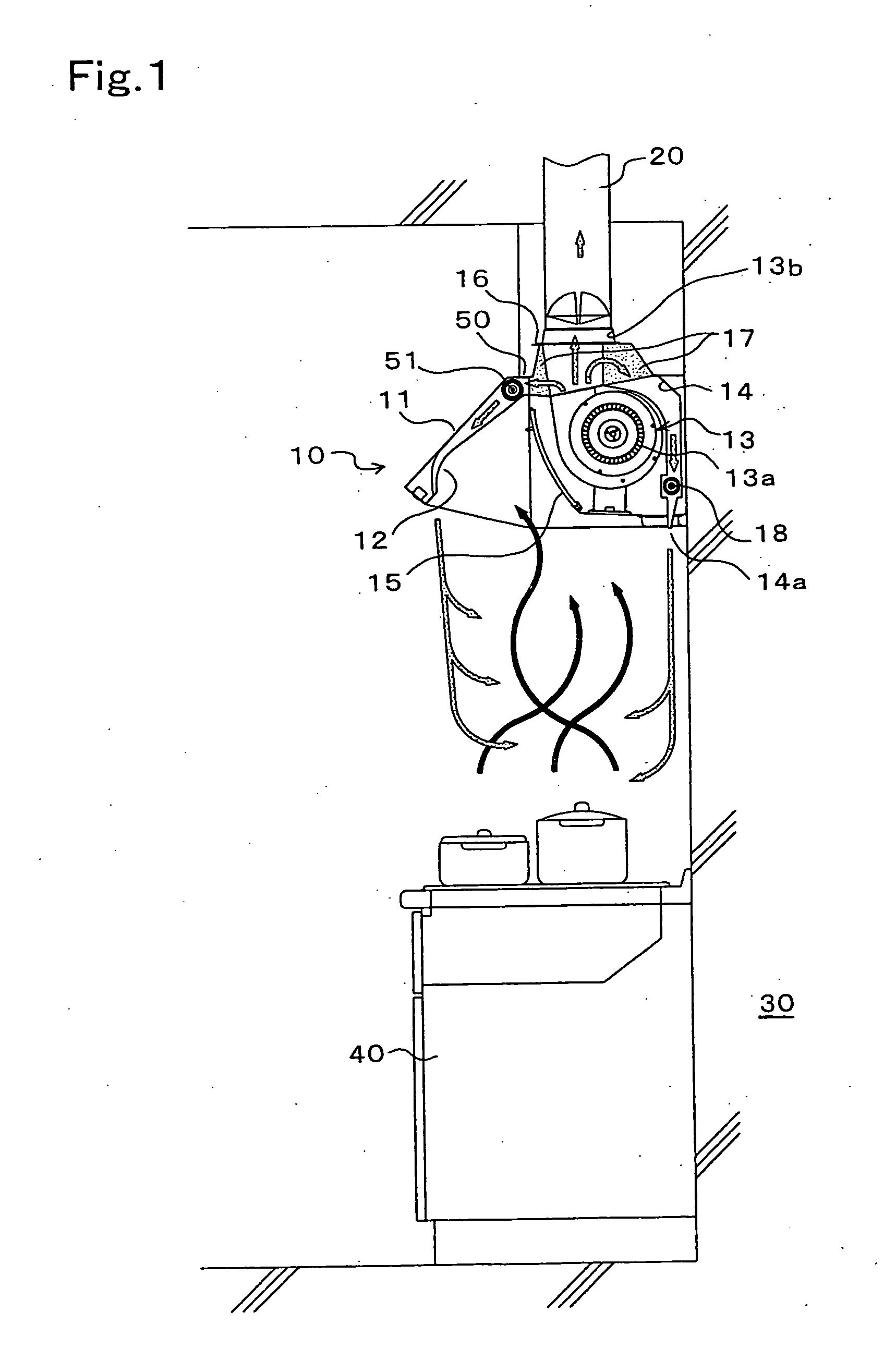

Range hood

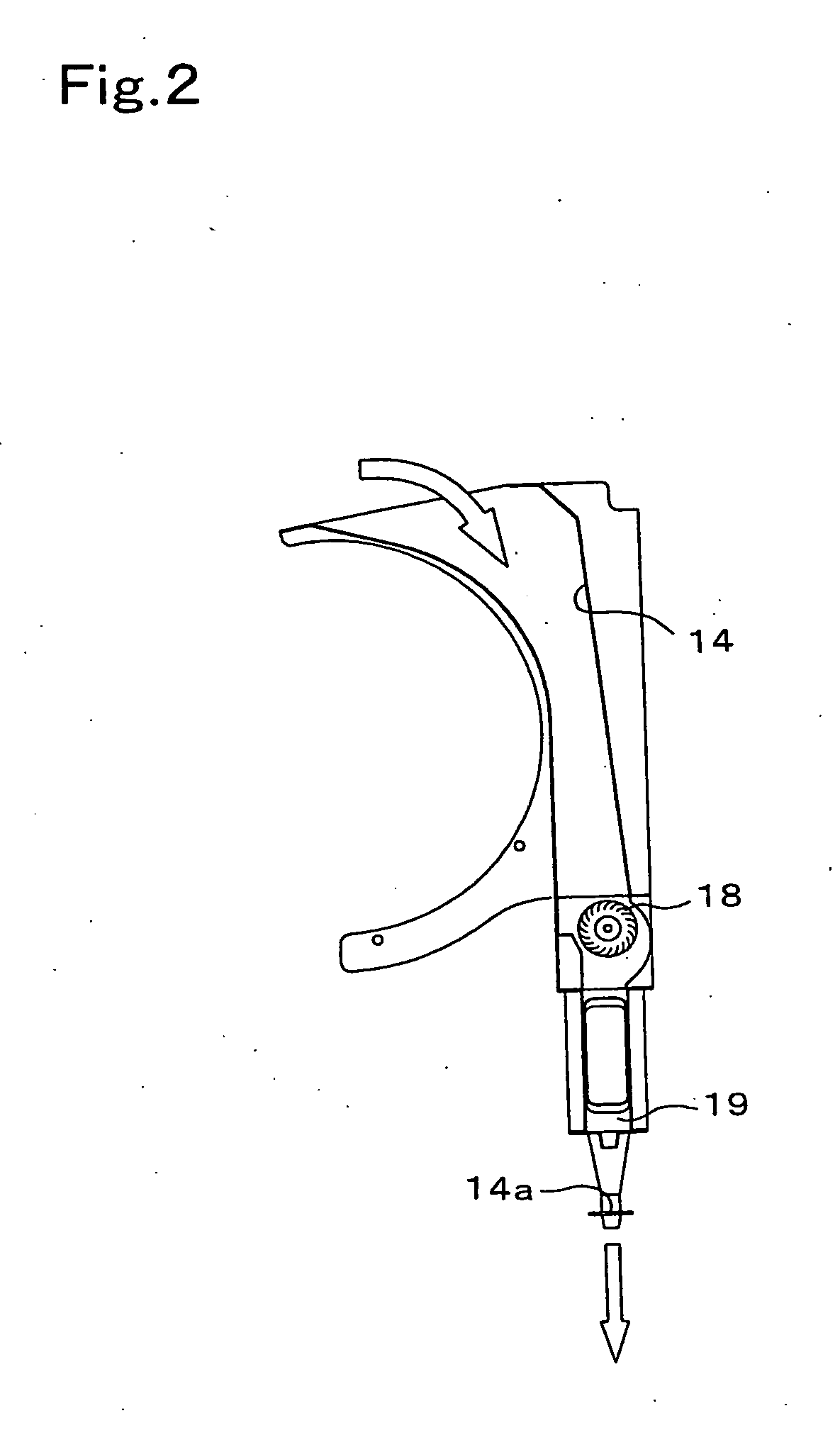

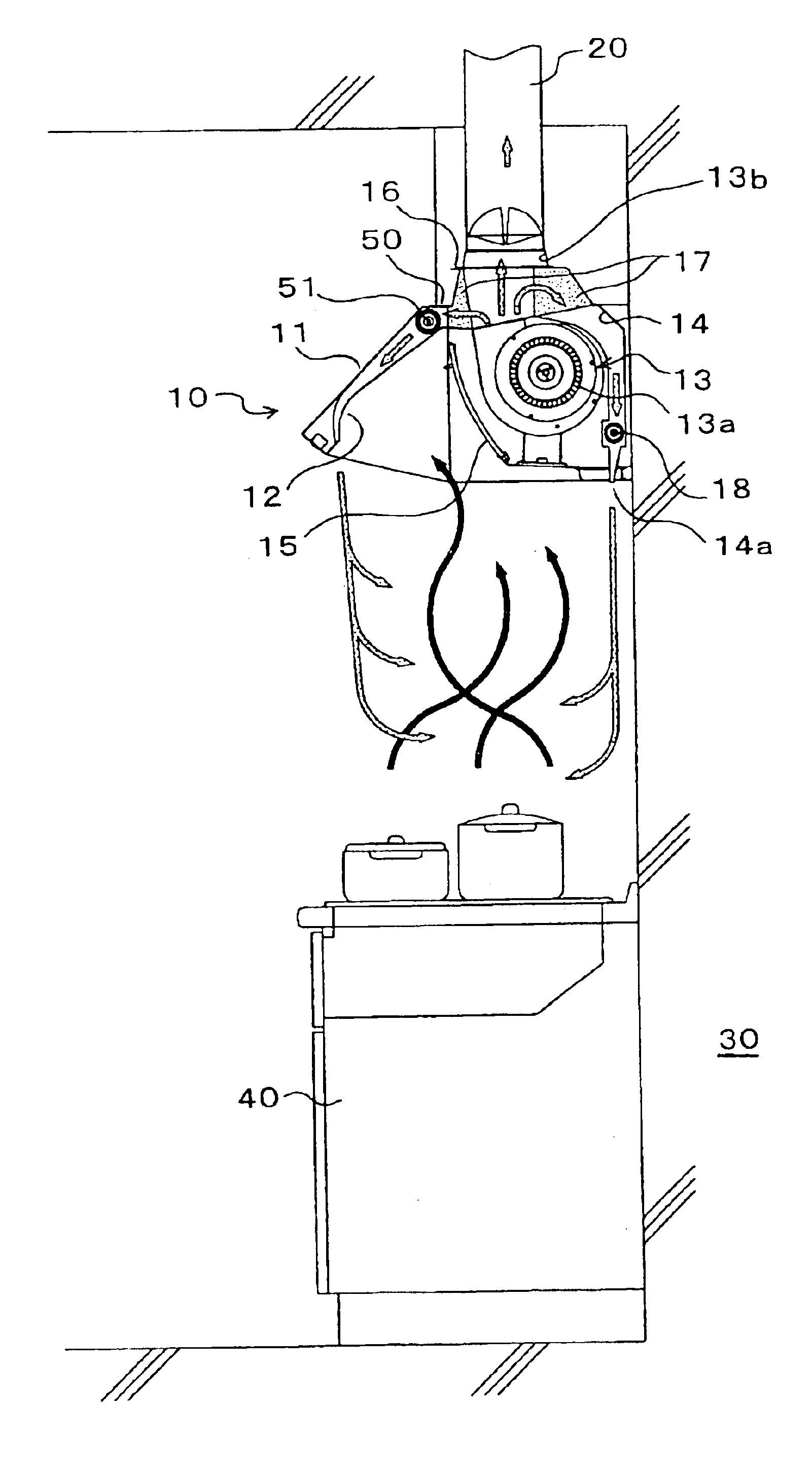

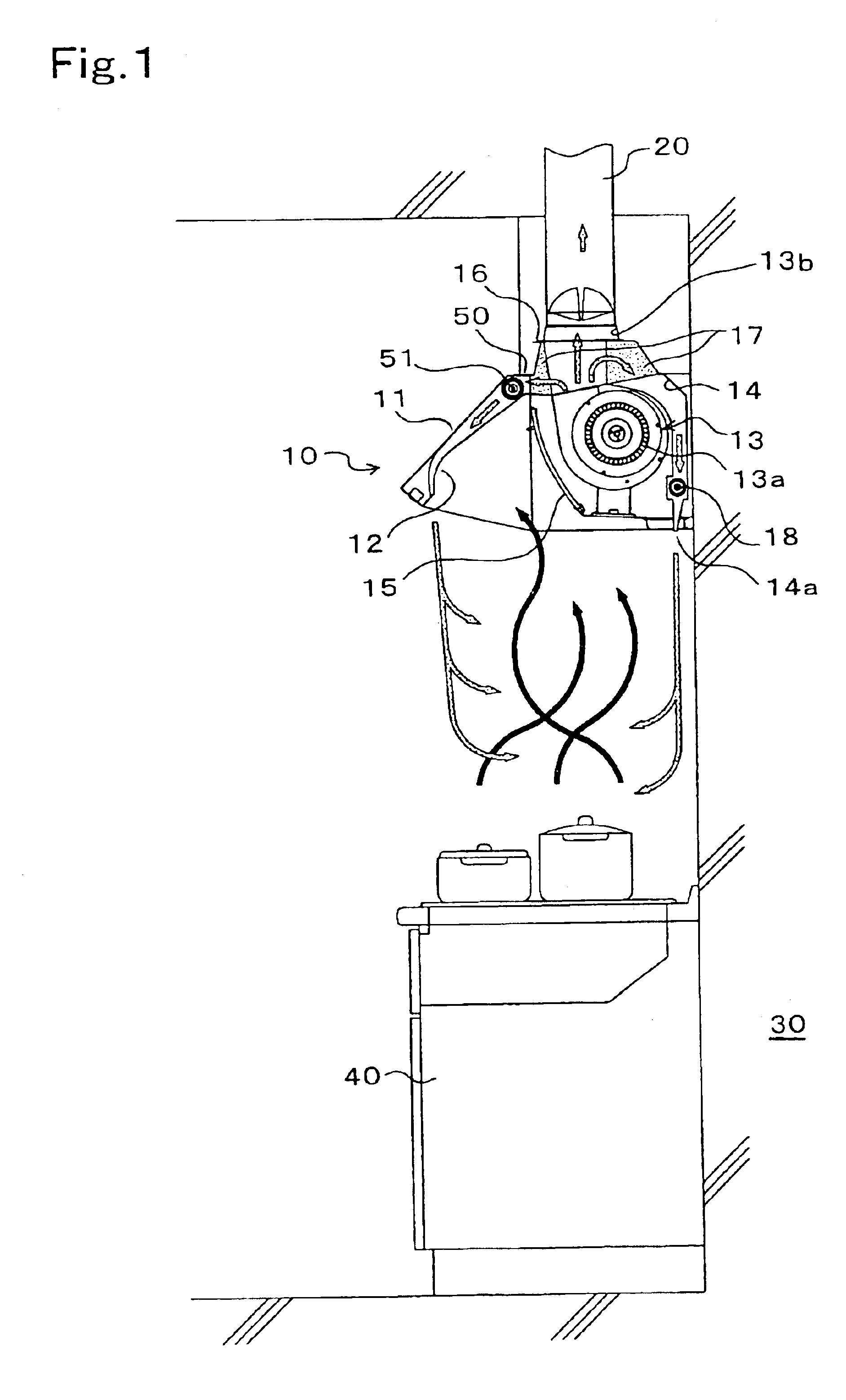

InactiveUS20050051159A1Avoid fumeAvoid accumulationDomestic stoves or rangesSpace heating and ventilation safety systemsEngineeringSmoke

The present invention relates to a range hood for evacuating air or emitted gas, which contains oily smoke and the like generated by cooking on a range, to the outside of a house.

Owner:YAMAZEN

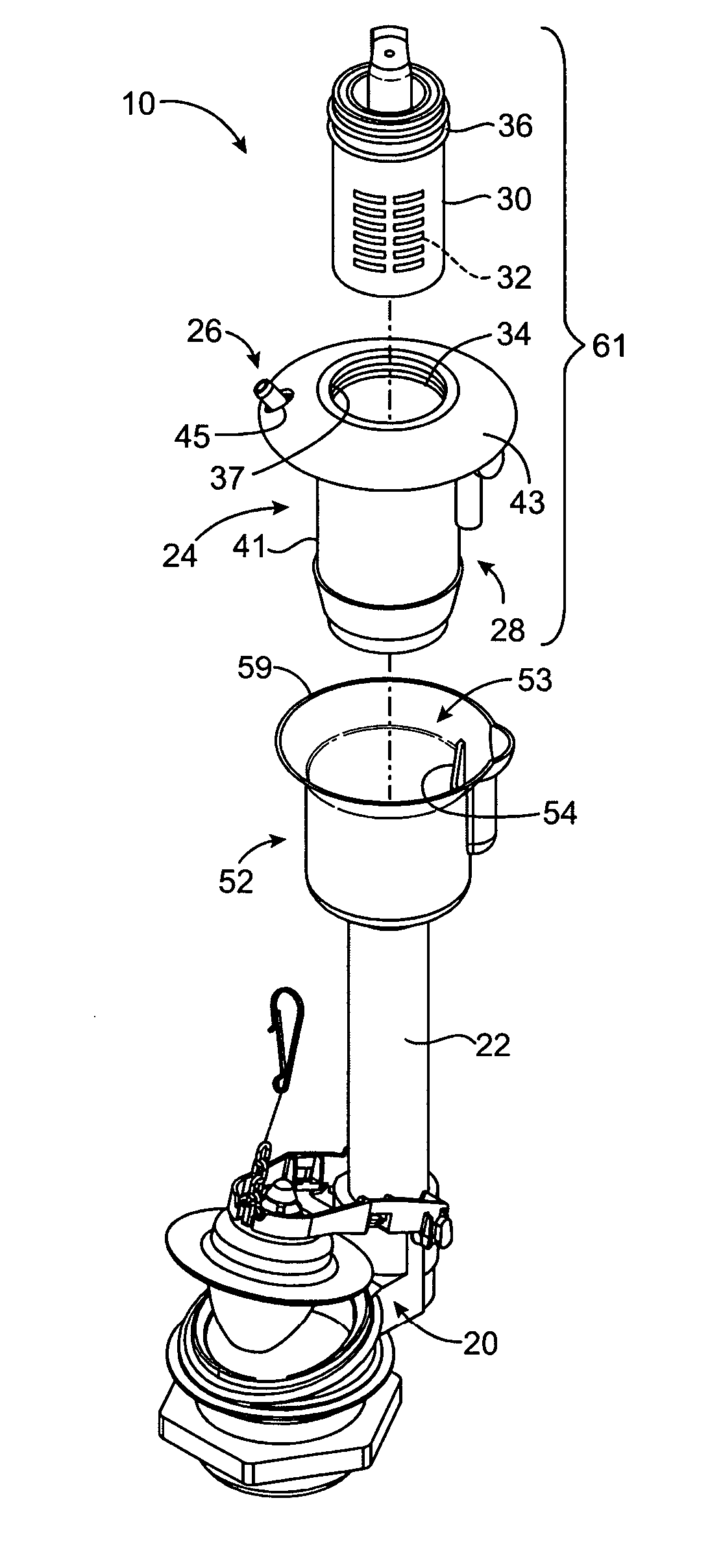

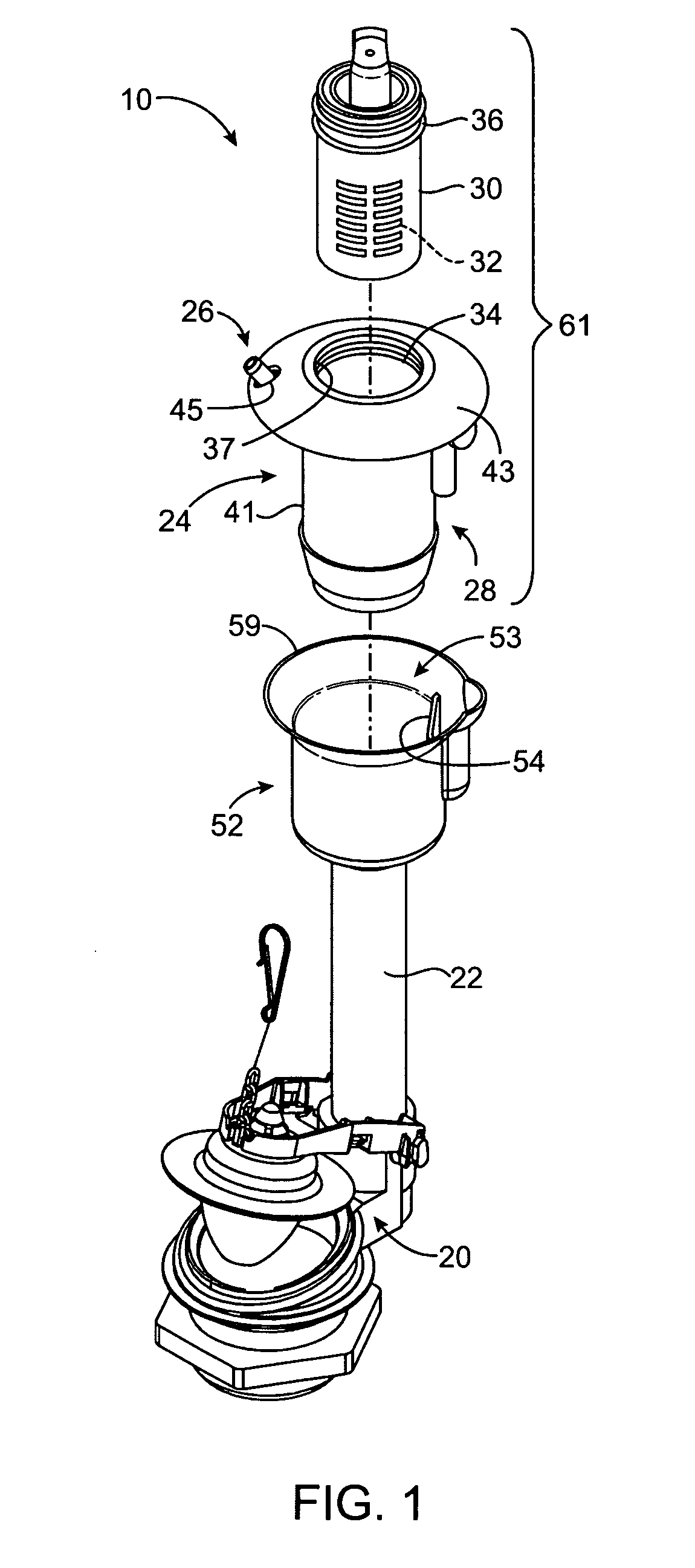

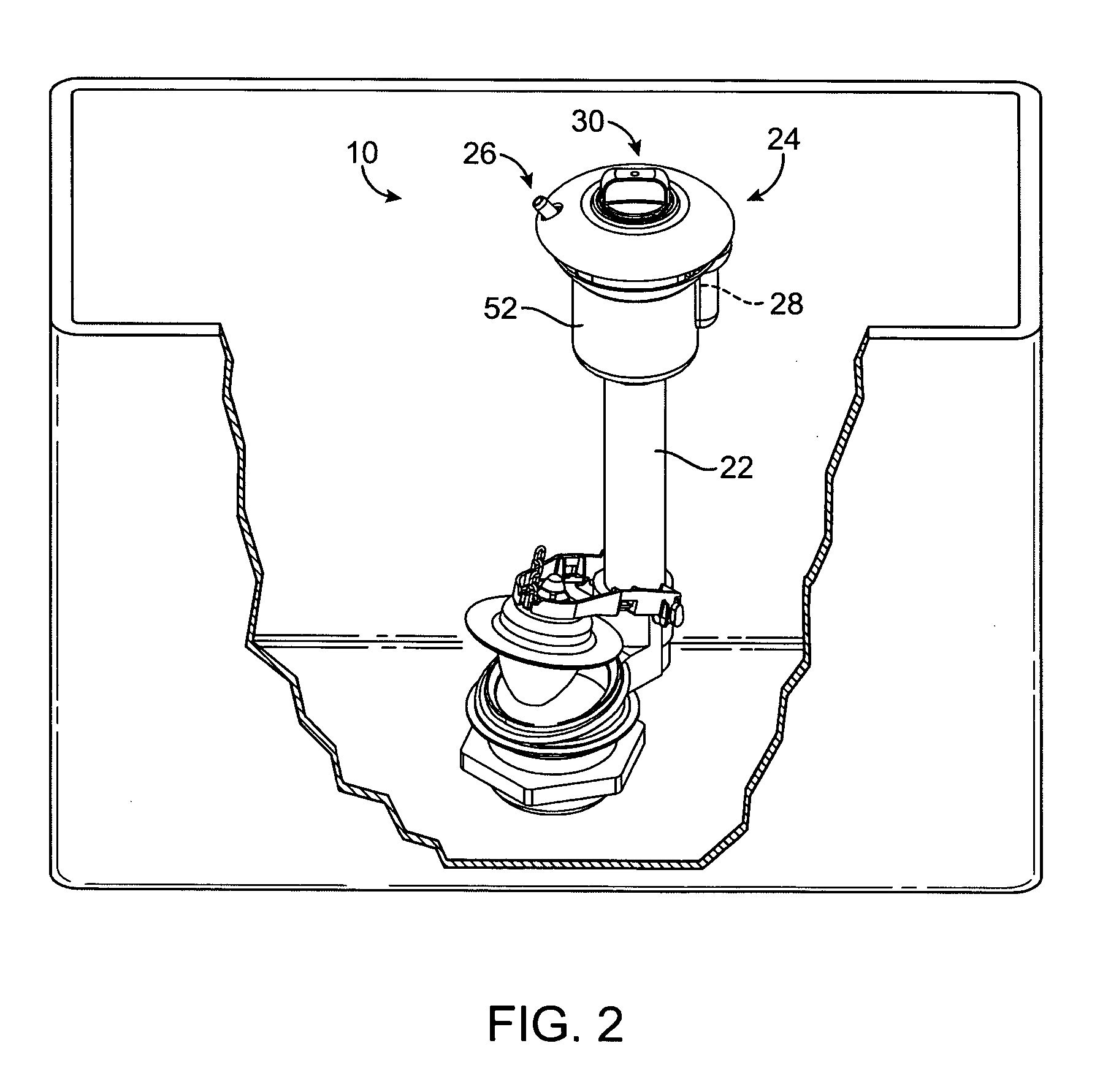

Flush valve cleaner dispenser system

A toilet cleaner dispenser system is centered above an overflow tube and configured to deliver cleanser solution directly to the overflow tube without a hose. A disposable cartridge containing a cleanser tablet is removably coupled to a dispenser housing. Refill water is directed to the housing through an inlet and brought into contact with the cleanser tablet to form a cleanser solution. The cleanser solution exits an outlet of the housing into a receptacle which directs the solution downwardly and directly into the overflow tube. Inlet and outlet water traps prevent fumes from escaping the housing.

Owner:FLUIDMASTER

Range hood

InactiveUS6945244B2Avoid fumeAvoid accumulationDomestic stoves or rangesSpace heating and ventilation safety systemsMechanical engineeringPhysics

The present invention relates to a range hood for evacuating air or emitted gas, which contains oily smoke and the like generated by cooking on a range, to the outside of a house.

Owner:YAMAZEN

Cooking device with compact structure preventing oil fume

InactiveUS20170245681A1Compact structureEasy to meetMultiple-unit cooking vesselsVessels with intergral heatingEngineeringSurface plate

Owner:SHENZHEN ZEZHI INTPROP CO LTD

Uniform-temperature vacuum smokeless pot

The invention discloses a uniform-temperature vacuum smokeless pot which comprises an inner pot and an outer pot. A pot edge of the inner pot is directly and integrally welded with a pot edge of the outer pot, fins are connected between the inner pot and the outer pot, the inner pot, the outer pot and the fins are integrally welded, a cavity is formed between the inner pot and the outer pot, a working medium is added into the cavity, and the inside of the cavity is vacuum, so that a vacuum cavity is formed. When the smokeless pot is used, if one point is heated in a temperature concentrated manner, the temperature of the integrated pot can be almost in equal state, stir-fry can be decreased, energy is saved, the temperature of the surface of the pot cannot be high, the pot is not easily pasted, edible oil does not easily reach a boiling point, a large number of lampblack is avoided, the appearance style, the size, the thickness and the weight of the smokeless pot are not different from those of a common pot, and the smokeless pot is suitable for domestic use.

Owner:王玉峰

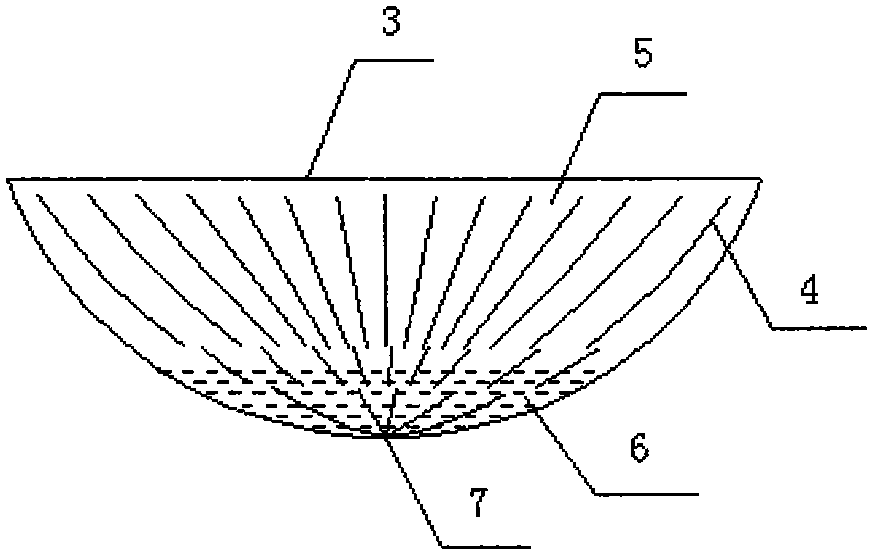

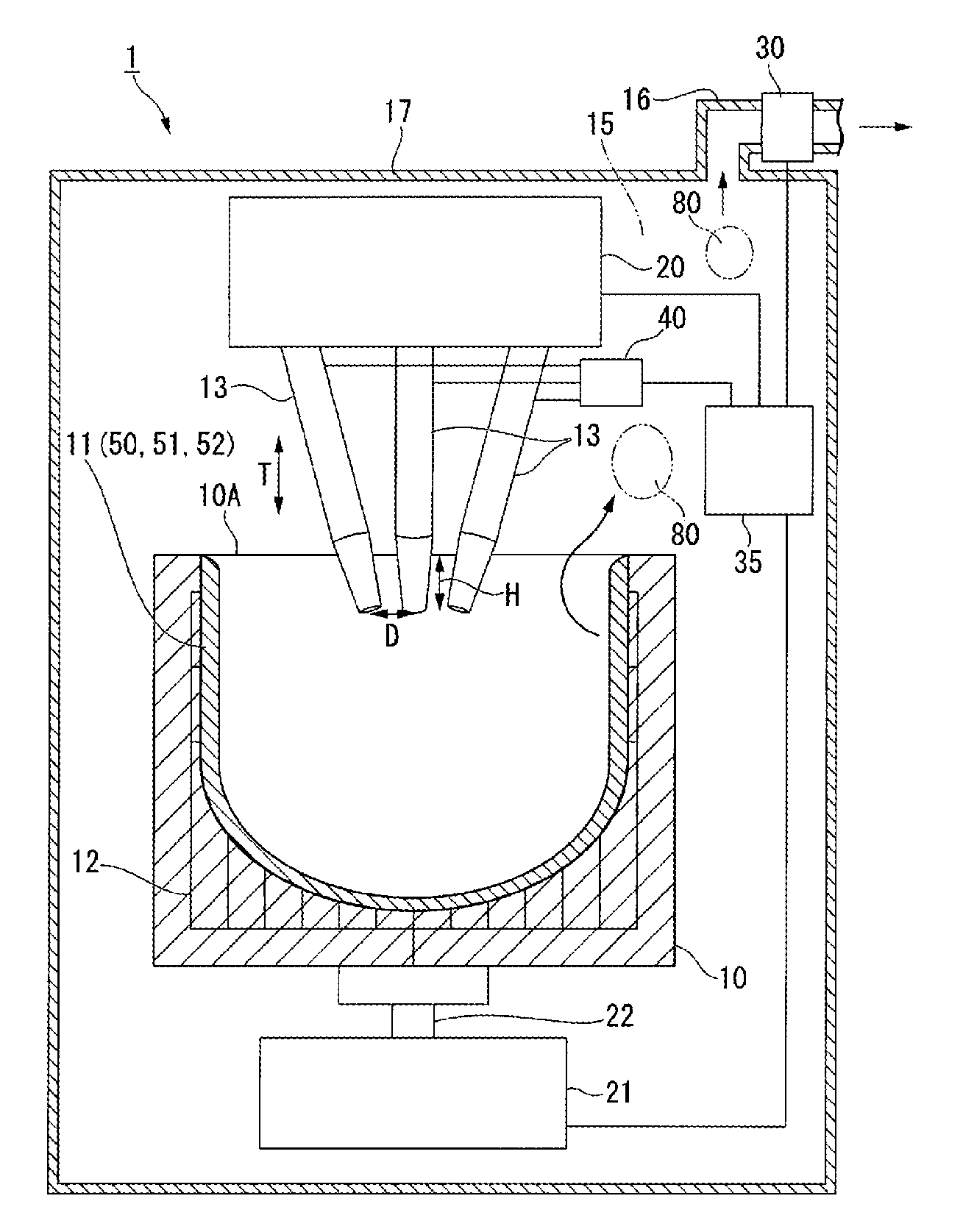

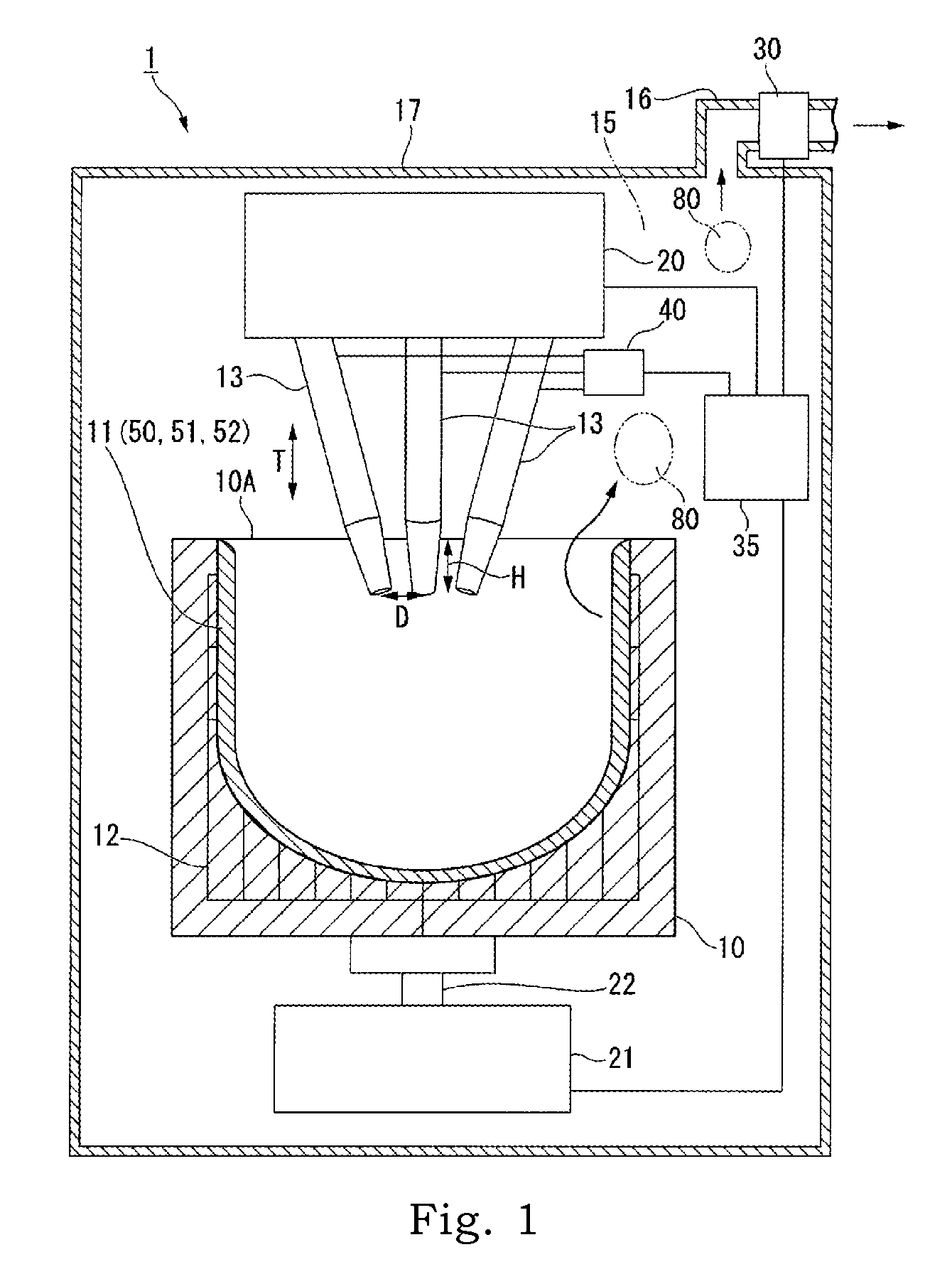

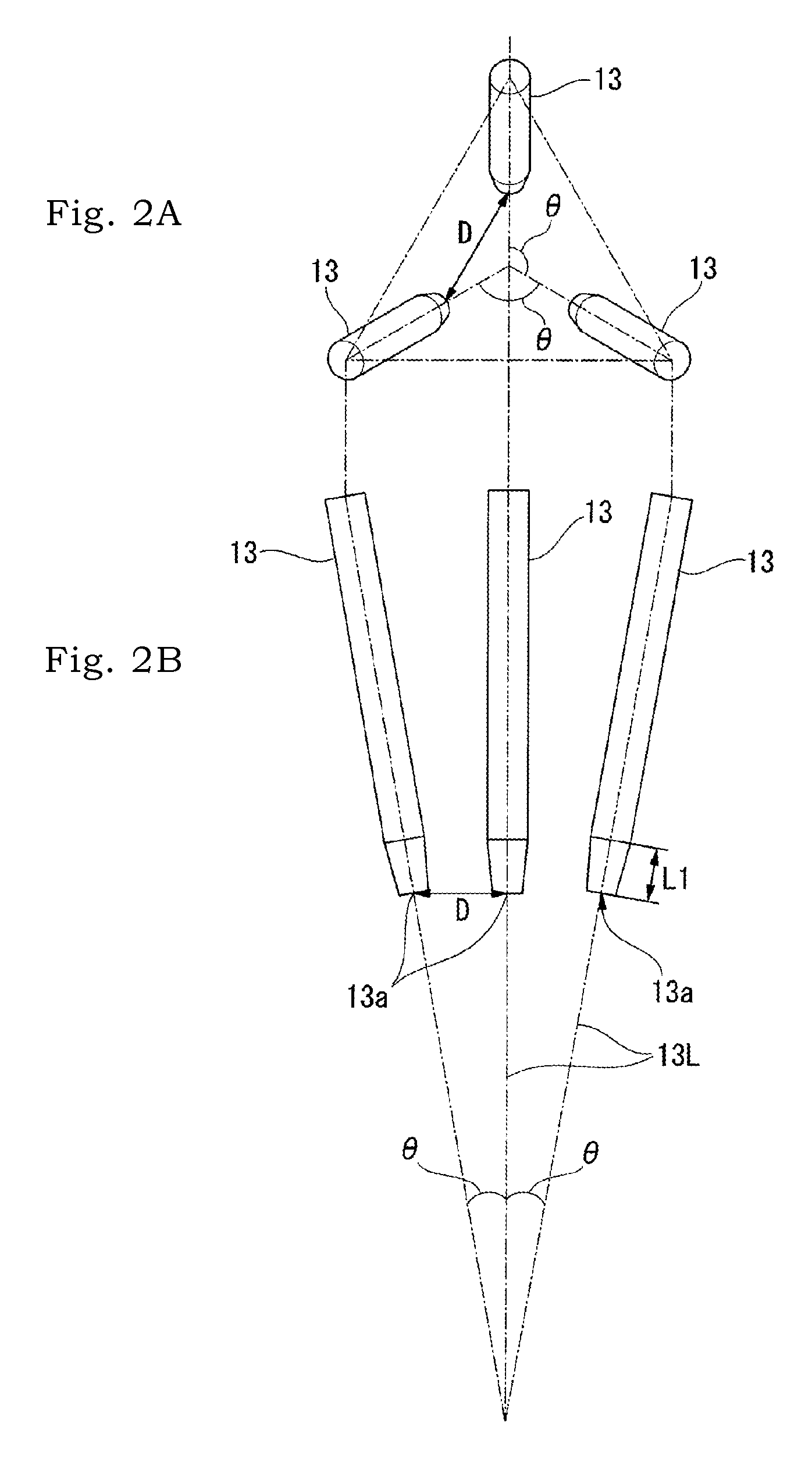

Apparatus and method for manufacturing vitreous silica crucible

ActiveUS20110079047A1Stable quality controlGood inner surface propertyBlowing machine gearingsGlass furnace apparatusCrucibleTime control

Provided are an apparatus and a method for manufacturing a vitreous silica crucible, which enable accurate measurement of a fume generation amount, prevention of deterioration of an inner surface property, and real-time control of a raw material melting state. Provided is an apparatus for manufacturing a vitreous silica crucible 50 by supplying silica powder into a mold 10 to form a silica powder layer 11, and heating and melting the silica powder layer 11 by arc discharge. The apparatus includes the mold 10 for defining an outer shape of a vitreous silica crucible, an arc discharge unit having a plurality of carbon electrodes 13 and a power-supply unit 40, and a fume-amount measurement unit 30 for detecting an amount of fumes 80 generated in the mold 10.

Owner:SUMCO CORP

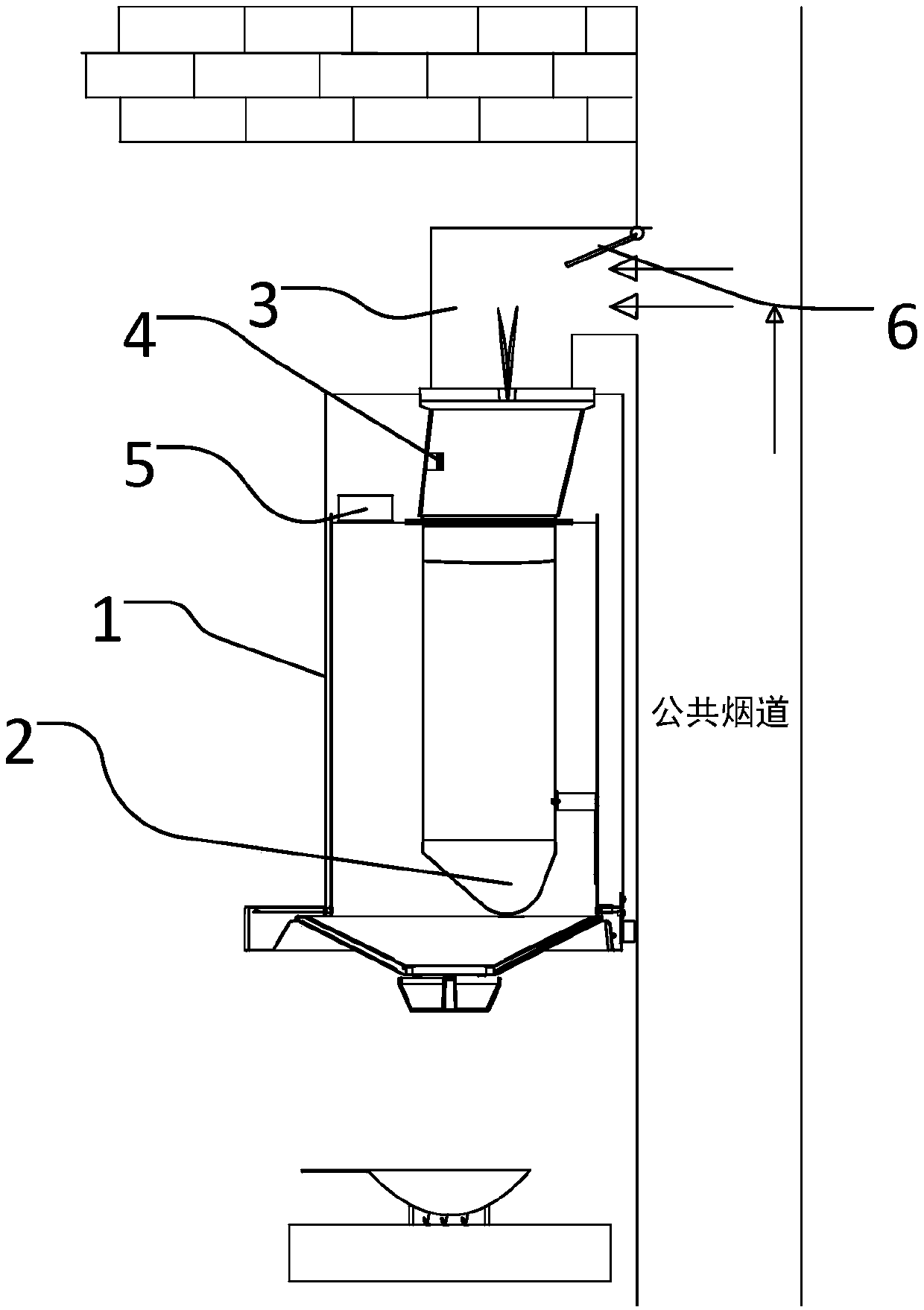

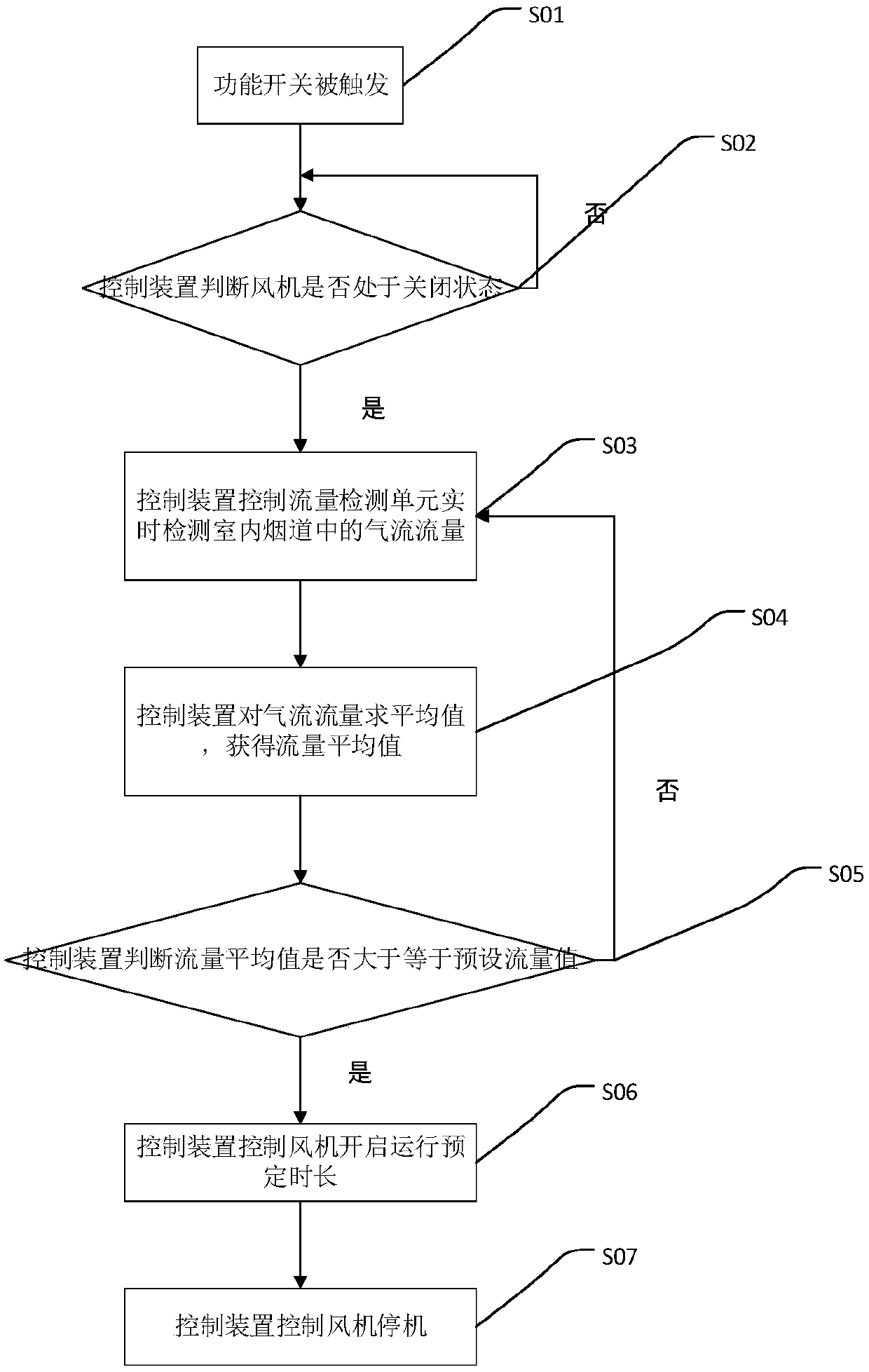

Range hood and control method thereof

PendingCN107763690APrevent backflowAvoid odorDomestic stoves or rangesLighting and heating apparatusEmbedded systemFlue

The invention provides a range hood and a control method thereof. The range hood comprises an indoor flue, a control device and a fan, wherein a detection device connected with the control device is arranged in the indoor flue; the control device is used for controlling the fan according to detection results of the detection device when the fan is at a stop state. By adopting the range hood and the control method provided by the invention, cooking fume in a public flue is effectively prevented from flowing back into an indoor flue, a kitchen can be prevented from odor or cooking fume, fresh and natural air is ensured for the kitchen, and the user experience is improved.

Owner:GREE ELECTRIC APPLIANCES INC

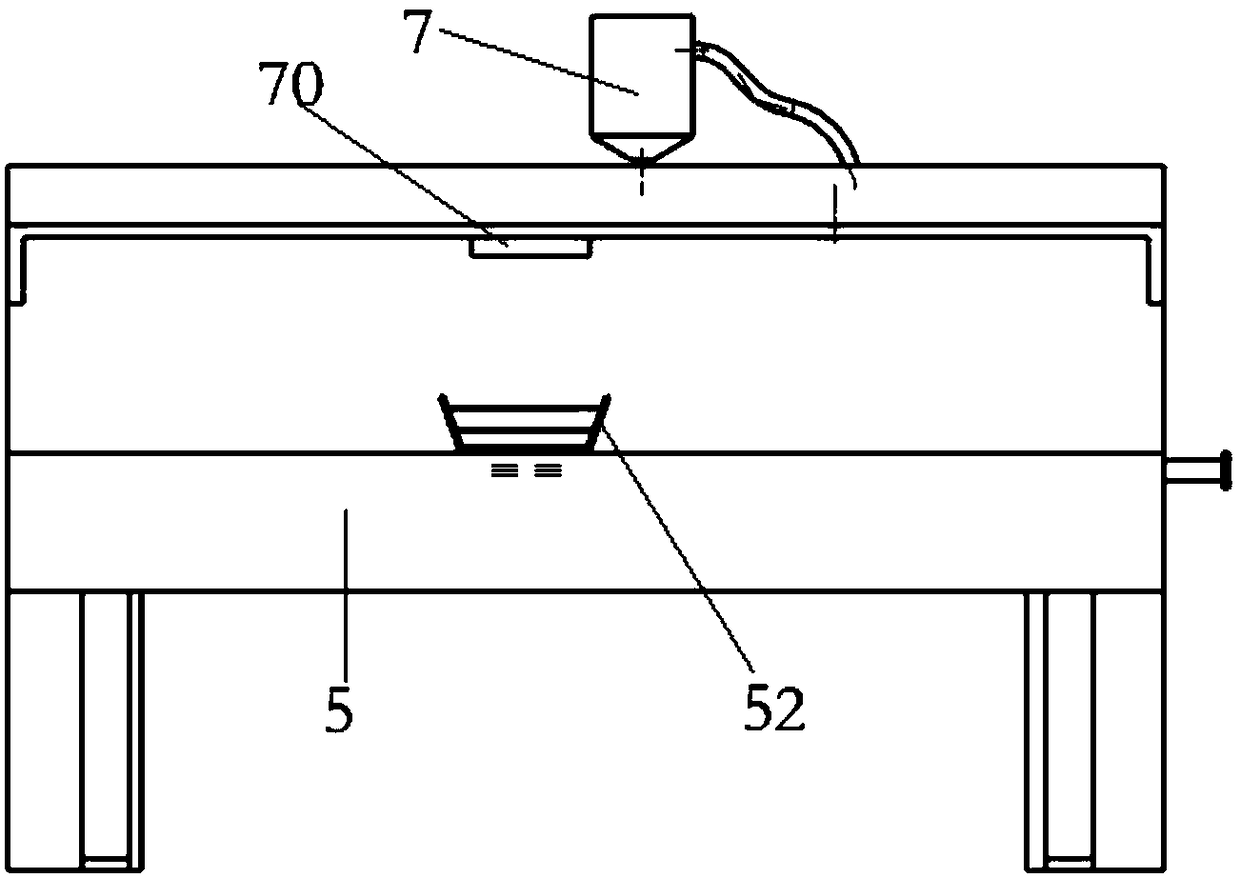

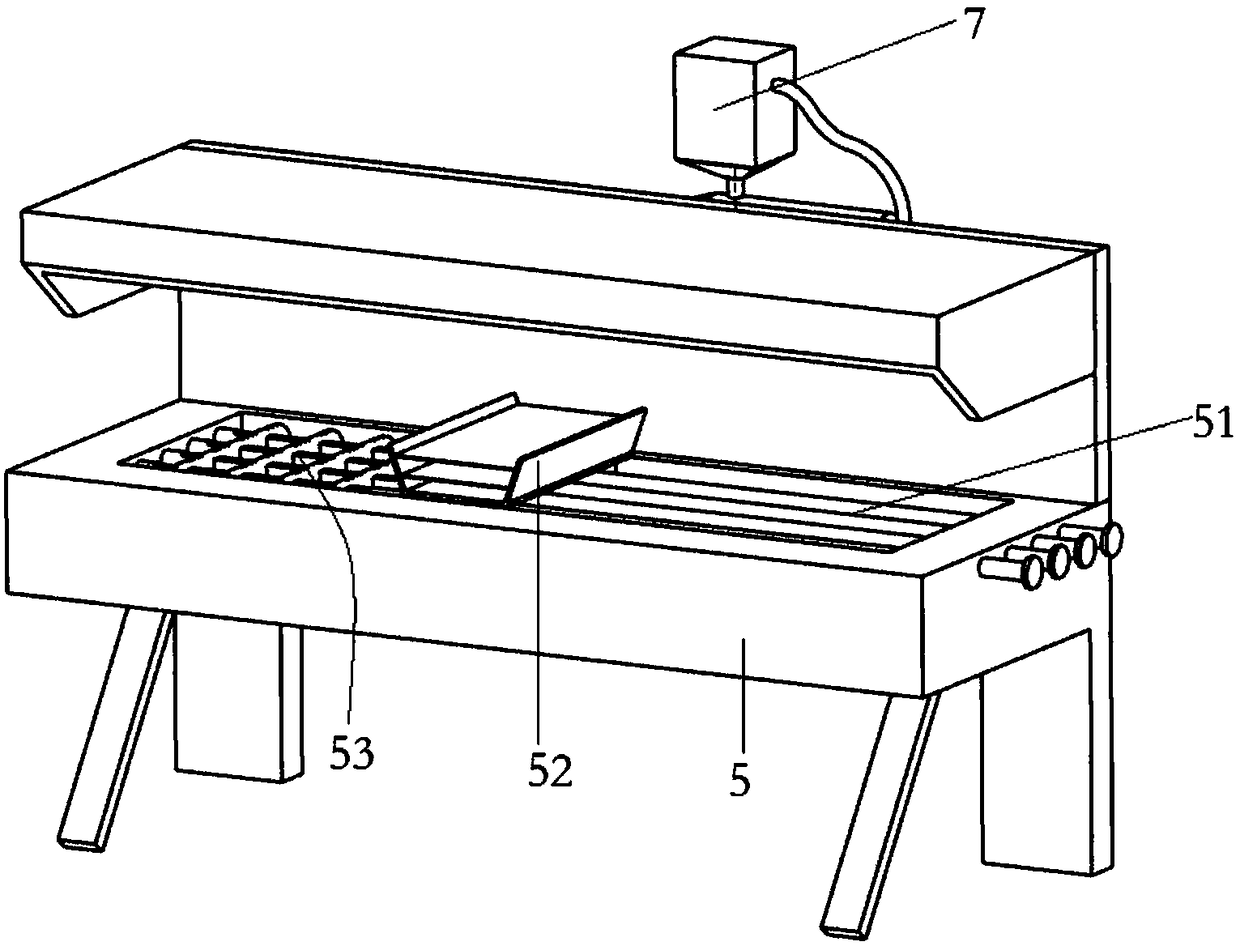

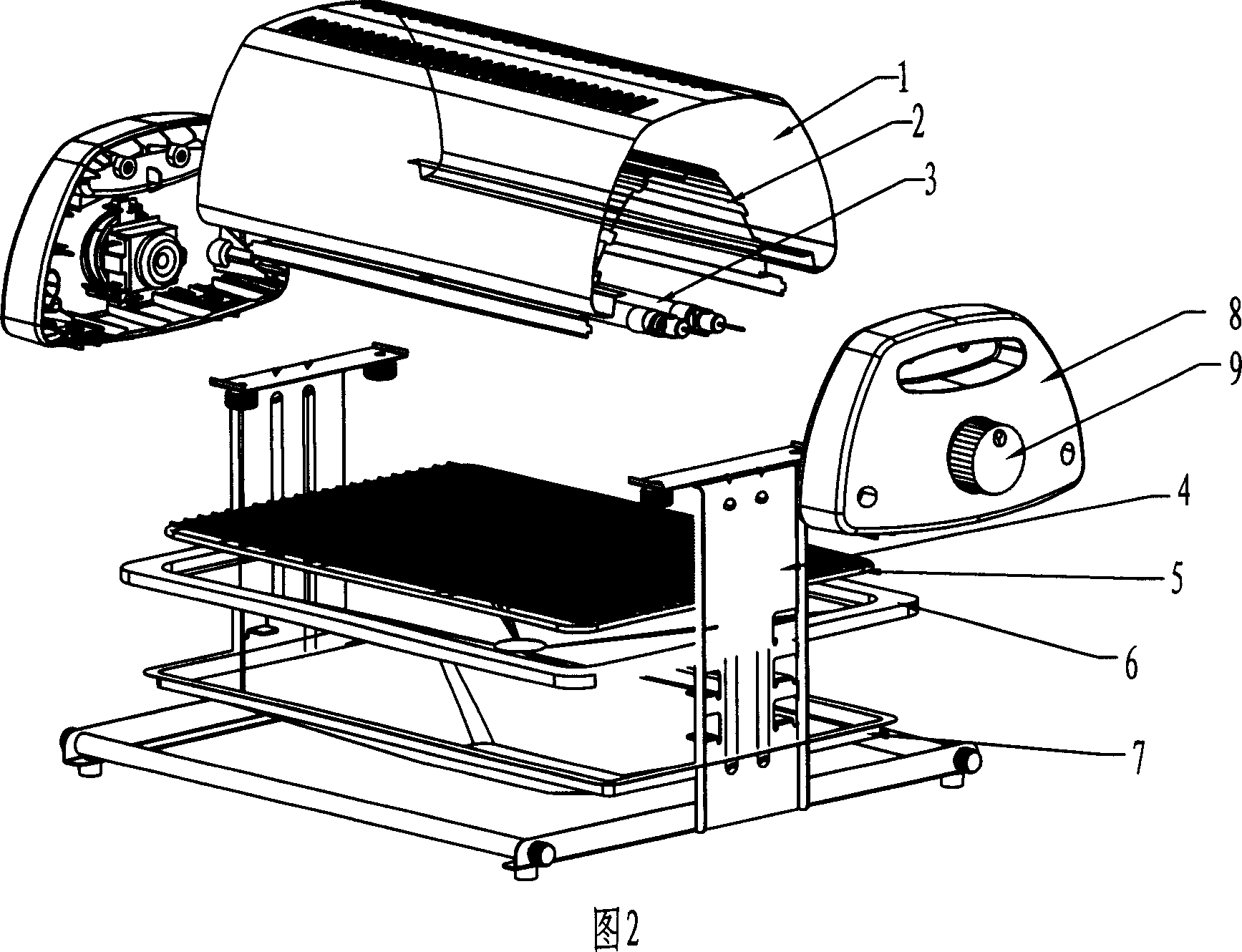

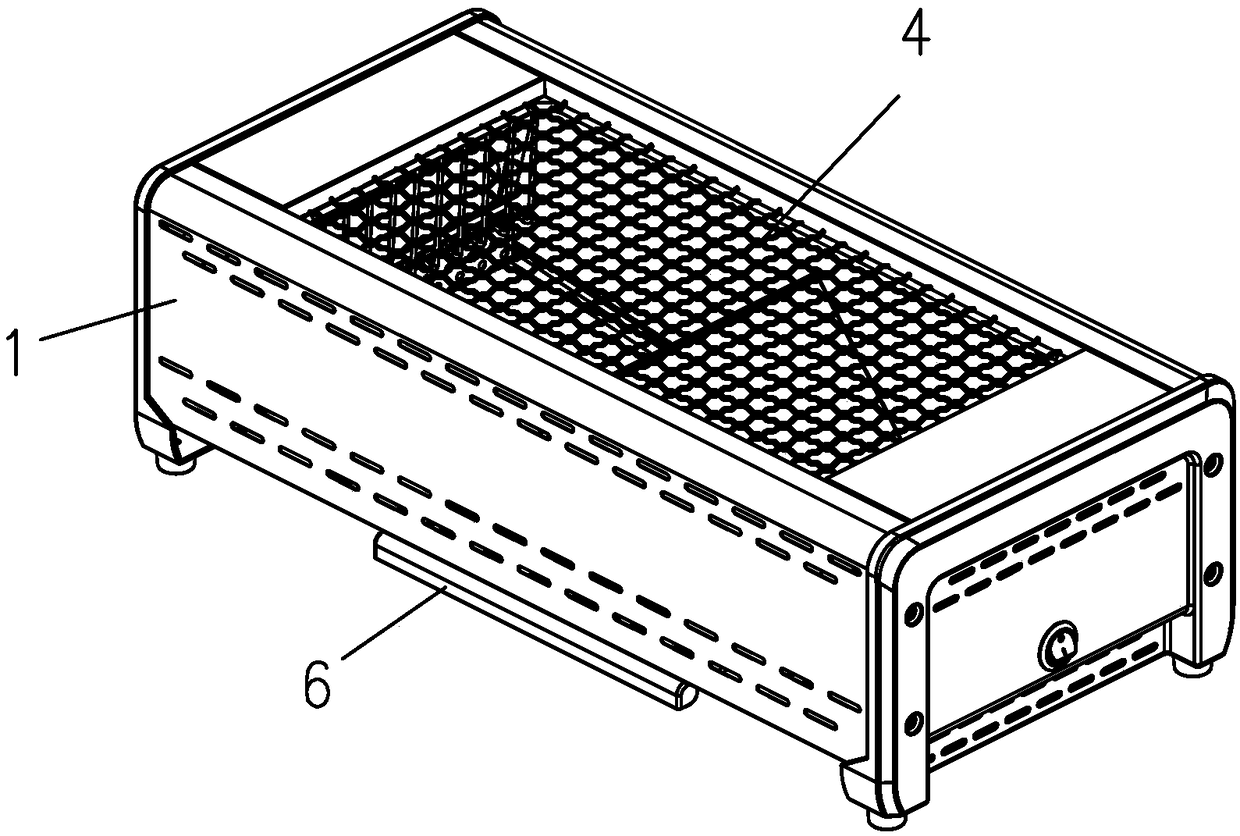

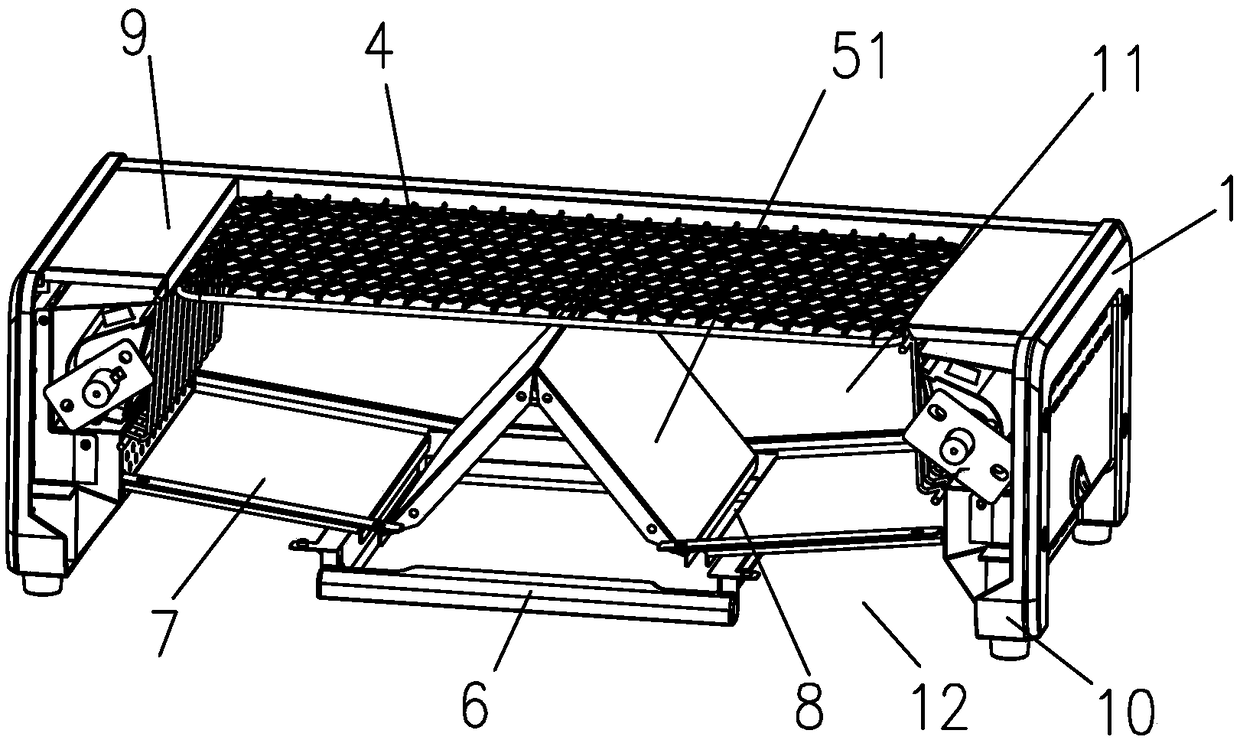

Environment-friendly grilling machine capable of absorbing smoke and method of environment-friendly grilling machine

ActiveCN108523691AEvenly heatedSlow down heat dissipationCombination devicesGas treatmentPulp and paper industrySmoke

The invention discloses an environment-friendly grilling machine capable of absorbing smoke and a method of the environment-friendly grilling machine. The environment-friendly grilling machine comprises a grilling machine body, the grilling machine body is in a rectangular groove shape, a grill of the grilling machine body comprises a first grill body and a second grill body, and the first grill body and the second grill body are adjacent in the length direction of the grilling machine body; a heat preservation assembly is arranged between the first grill body and the second grill body and arranged on the grilling machine body, the grilling machine body is further provided with a smoke absorbing assembly, and a smoke absorbing device is located above the grill and absorbs the smoke above the grill. According to the environment-friendly grilling machine capable of absorbing the smoke and the method of the environment-friendly grilling machine, the content of the smoke exhausted into airis reduced.

Owner:盐城抱璞文化传媒有限公司

Movable suspension multifunction roast duck oven using coke

A movable suspending-type multifunctional coke over for roasting duck is composed of oven, coke stove, rotary hanger, oil collector, temp display, observing lamp, blower and moving unit. Its advantages are small size of oven, light weight, and good thermal insulation property, using coke as fuel, no smoke and harmful gas generation, no pollution, and high quality of roast duck.

Owner:张黑喜

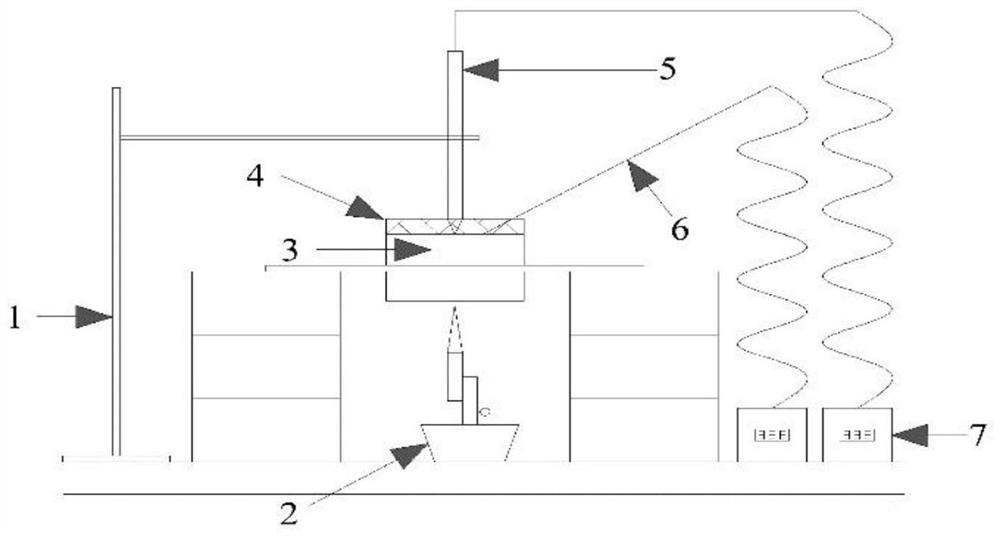

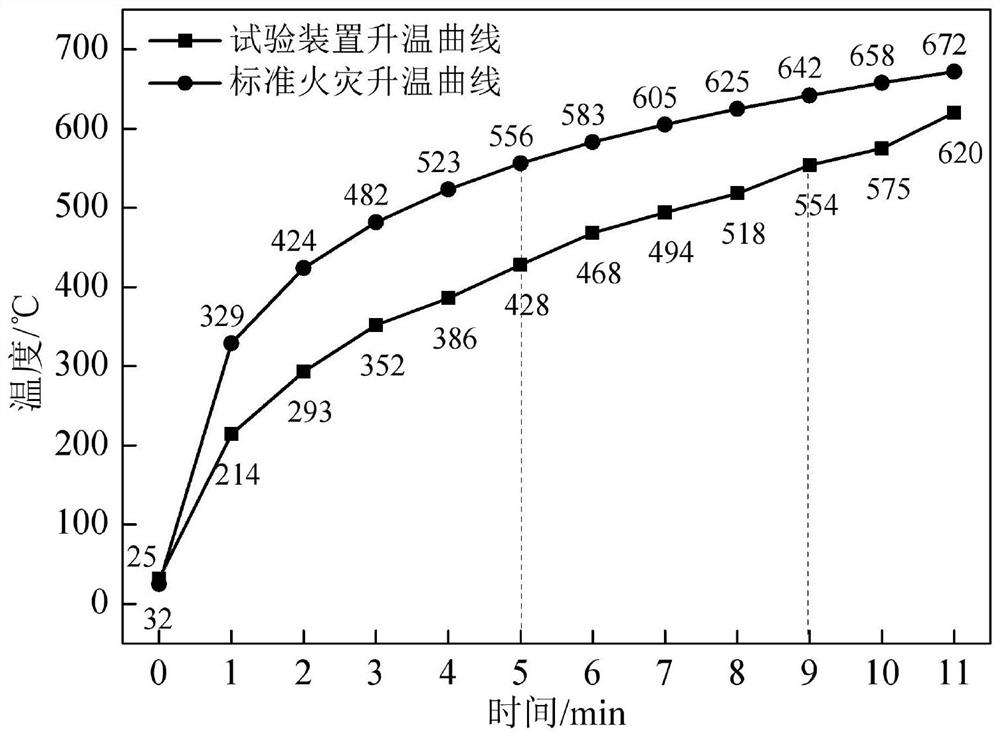

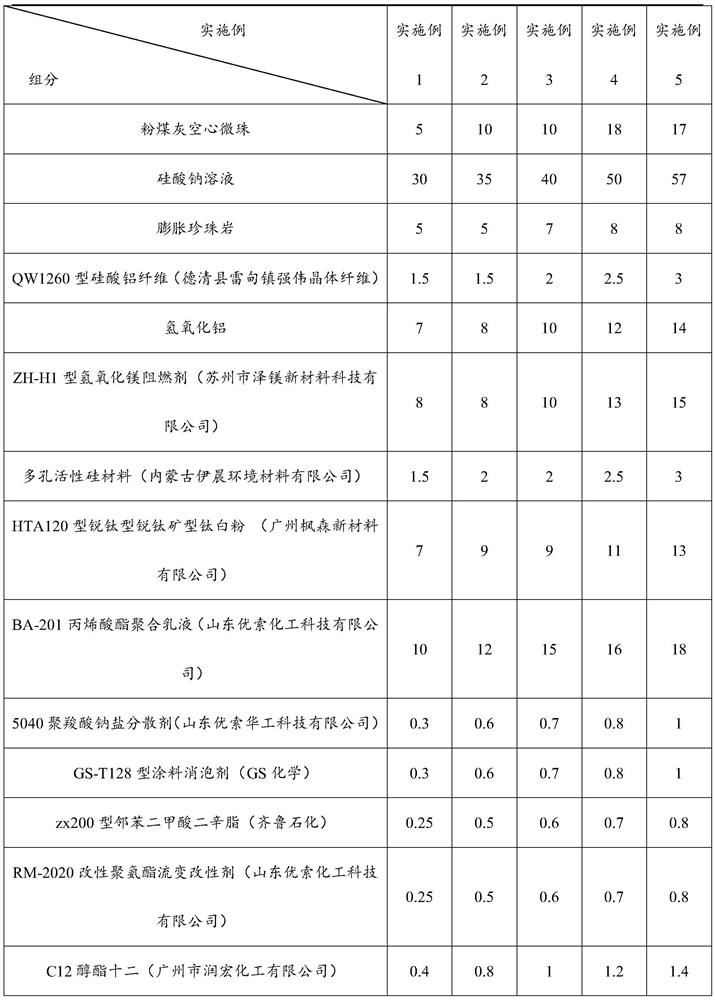

Indoor thick steel structure fireproof coating and preparation method thereof

ActiveCN112251057AImprove flame retardant performanceGood chemical stabilityFireproof paintsAlkali metal silicate coatingsEmulsionPlasticizer

The invention provides an indoor thick steel structure fireproof coating, which relates to the technical field of fireproof coatings, and comprises the following components by mass: 5-20 parts of flyash hollow microspheres, 20-60 parts of a sodium silicate solution, 5-10 parts of expanded perlite, 1-3 parts of aluminum silicate fiber, 5-15 parts of aluminum hydroxide, 5-15 parts of magnesium hydroxide, 1-3 parts of a porous active silicon material, 5-15 parts of titanium dioxide, 10-20 parts of apure acrylic emulsion, 0.2-1 part of adispersive agent, 0.2-1 part of an antifoaming agent, 0.2-1part of a plasticizer, 0.2-1 part of a leveling agent, 0.2-1.5 parts of a coalescing agent and 20-60 parts of water. According to the invention, the small-particle-size hollow microspheres are used asa filler, and the sodium silicate solution prepared from the screened residual large-particle-size hollow microspheres is used as a binder of the coating, so that the resource reutilization is realized, and the fireproof coating has excellent physical and chemical properties and heat insulation and flame retardancy under the condition of not using cement.

Owner:INNER MONGOLIA UNIV OF TECH

Temperature-sensing device structure of electromagnetic heater

InactiveCN101113928AAccurate temperature controlAvoid fumeThermometer detailsDomestic stoves or rangesThermistorTemperature sensing

A temperature sensing implement structure of an electromagnetic stove comprises a crystallite board, a thermal resistance, etc. The invention is characterized in that: the copper board and the thermal resistance constitute a temperature sensing implement which can closely contact with a stainless steel boiler to precisely detect the temperature in the boiler, an insulation layer is additionally arranged between the crystallite board and a wire disk. The invention has the beneficial effects that: because the temperature sensing implement closely contacts with the bottom of the stainless steel boiler, the temperature control is very precise, so the intelligent control of the frying dishes without soot and cooking rice are achieved, because the existing electromagnetic stove can not precisely detect the temperature in the boiler, the functions can not achieved; because the insulation layer is additionally arranged between the crystallite board and the wire disk, the heat on the crystallite board is prevented from transferring to the body, the temperature in the electromagnetic stove body is effectively reduced, and at the same time the burnout of the wire disk is prevented.

Owner:胡述斌

Cooking device with sealing unit

ActiveUS10674854B2Avoid fumeCooking-vessel lids/coversSteam cooking vesselsThermodynamicsEngineering

A cooking device includes a base, a housing, a lid, a control module, a heating module and an exhaust module. The heating module includes bottom heating units disposed at different locations inside a storage compartment of the housing. The exhaust module includes an air-filled element, an air-extraction element, an inlet passage, and an exhaust passage used to exhaust fog or oil flume generated in an inner pot(s). An inner surface of the lid is provided with multiple first sealing units, a second sealing unit and a third sealing unit. The third sealing unit is arranged corresponding to an opening of the storage compartment. The second sealing unit is connected with the third sealing unit to divide a region surrounded by the third sealing unit into sub-regions with different sizes. The first sealing units are arranged corresponding to the bottom heating units and in the sub-regions with different amounts.

Owner:SHENZHEN ZEZHI INTPROP CO LTD

Electric heating barbecue apparatus

InactiveCN1989887AIncrease profitAvoid lostBaking ovenHot plates heating arrangementsEngineeringHeat losses

The invention is an electric heating barbecue device which consists of reflectors, electric control, heat-generating pipe, frame and gridiron. The gridiron is installed on the frame, the upper reflector is installed up the gridiron and fixed on the upper of frame, the heat-generating pipe is fixed on the lower part of the upper reflector, the lower of gridiron is equipped with the lower reflector installed on the frame, the lower part of lower reflector is equipped with water plate installed on the frame and the base of the lower reflector contacts waterborne of water plate. The invention not only greatly increases the utilization of heat and avoids heat loss, thus increases its efficiency, but also avoids generating barbecue smoke, is suitable for indoor use. The invention is a reasonable design, convenient and practical electric heating barbecue device.

Owner:MIDEA GRP CO LTD

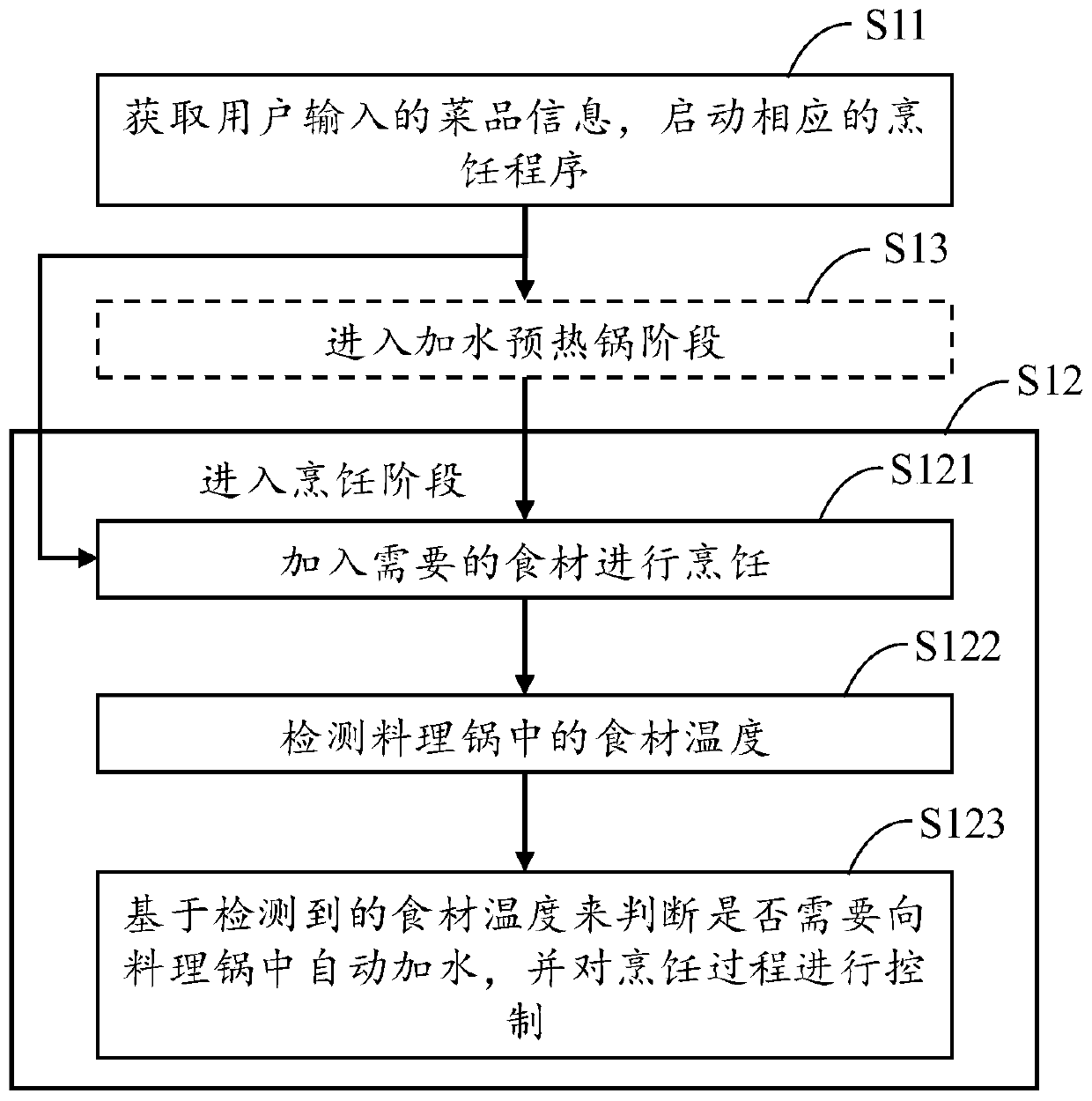

Cooking method

ActiveCN111481068ASolve the defect of not being able to better release the aroma of ingredientsGuaranteed tasteTime-controlled ignitorsProcess engineeringFood material

The embodiment of the invention provides a cooking method. The cooking method comprises the steps: entering a water adding and pot preheating stage comprising the steps: controlling to automatically add water into a cooking pot to heat and preheat the cooking pot; detecting the water temperature in the cooking pot; when the detected water temperature is smaller than a first preset temperature line, continuing to heat; and when the detected water temperature is not smaller than the first preset temperature line, maintaining the first set heating power, and heating and sustaining for a first preset duration; and entering a cooking stage comprising the steps: in the cooking process, detecting the temperature of food materials in the cooking pot; and whether water needs to be automatically added into the cooking pot or not is judged on the basis of the detected food material temperature, controlling the cooking process. The cooking method provided by the embodiment of the invention can effectively prevent the food materials from being burnt and burnt in the cooking process.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

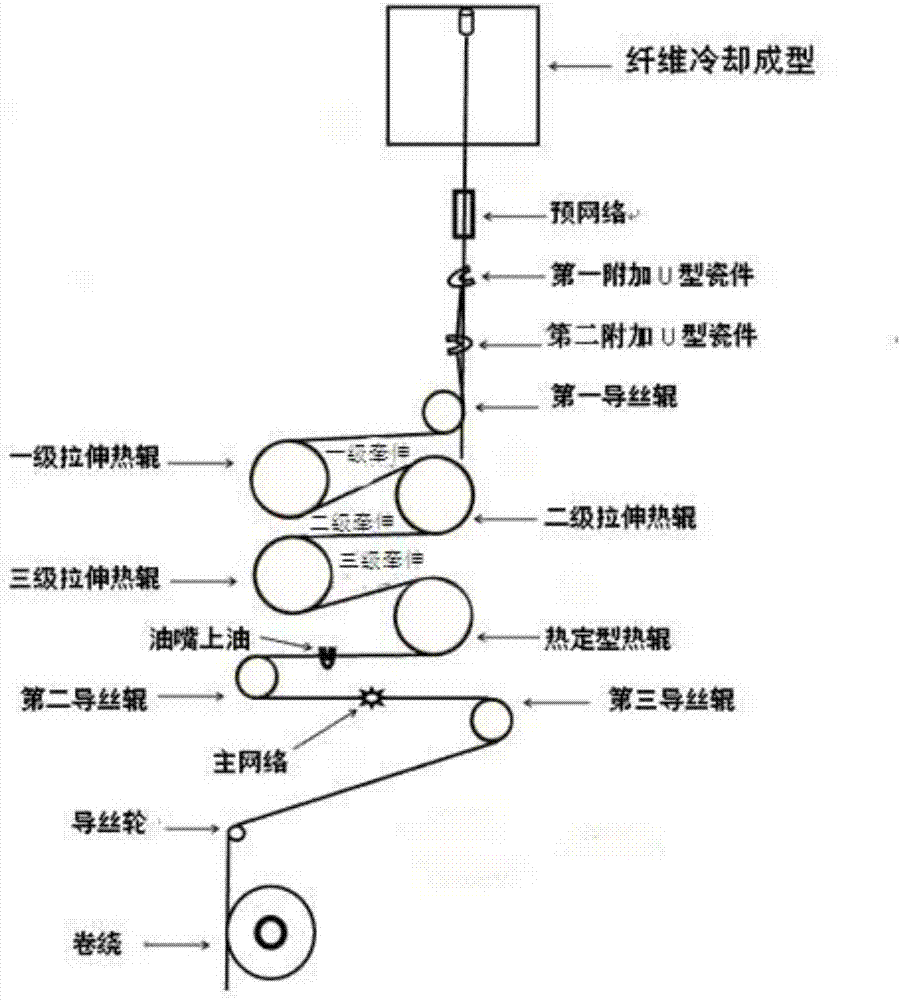

Production process of polyester FDY multi-roll oil-free full-draft fibers

InactiveCN107034533AAvoid slipping and shakingGuaranteed spinnabilityArtificial thread manufacturing machinesFilament manufacturePolyesterDistributor

The invention discloses a production process of polyester FDY multi-roll oil-free full-draft fibers. The production process includes the following steps that polymerization is conducted in a final polymerization autoclave, raw materials are then processed by means of a melt conveying pump, a melt distributor and a melt booster pump in sequence, the obtained melt is conveyed and then processed by means of a melt cooler, a static mixer, a melt distribution valve and a spinning box in sequence, then the melt is extruded in a metering pump and processed by means of a spinning assembly, fiber cooling and molding is conducted, then semi-finished fibers are processed by means of a U-shaped ceramic piece, a secondary network, a spinning channel, a first additional U-shaped ceramic piece1, a second U-shaped ceramic piece 2, a first silk guide roller, a first-level hot pulling roller, a second-level hot pulling roller, a third-level hot pulling roller and a heat-setting hot roller in sequence, a lubricating nipple is used for oiling, and the obtained fibers are processed by means of a second silk guide roller, a primary network, a third silk guide roller and a guide wheel and subjected to coiling, doffing, quality testing and packaging. According to the production process of the polyester FDY multi-roll oil-free full-draft fibers, the product quality is improved, the running environment of equipment and the working environment of workers in a FDY production place are optimized, yarn path operation is simplified, and energy conservation and high efficiency are achieved.

Owner:TONGKUN GRP ZHEJIANG HENGTONG CHEM FIBER

Cooking device with multiple heating units

ActiveUS10674853B2Avoid fumeCooking-vessel lids/coversSteam cooking vesselsMechanical engineeringPhysics

A cooking device includes a base, a housing, partition walls, a lid, a control module, an exhaust module, a connecting electrode and a heating module. The exhaust module includes an air-filled element, an air-extraction element, an inlet passage and an exhaust passage. The air-extraction element is used to exhaust fog or oil fume generated in the plurality of inner pots. The connecting electrode is arranged in a middle position of the base. The heating module includes: bottom heating units disposed different locations inside a storage compartment of the housing respectively and connected with the processor individually; second heating units arranged on the partition walls and connected with the connecting electrode by wires inside the partition walls; and third heating units arranged on the inner wall of the housing.

Owner:SHENZHEN ZEZHI INTPROP CO LTD

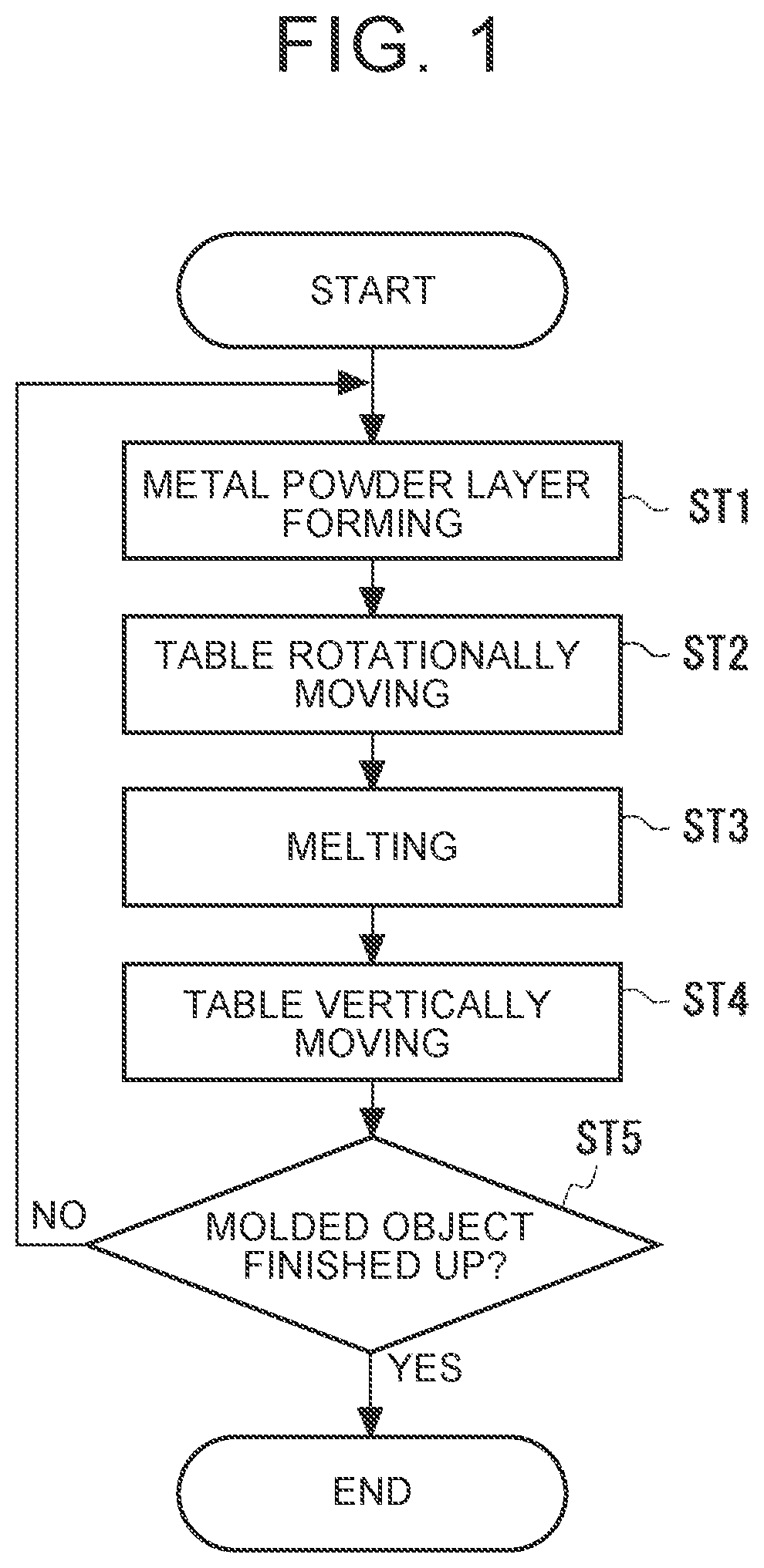

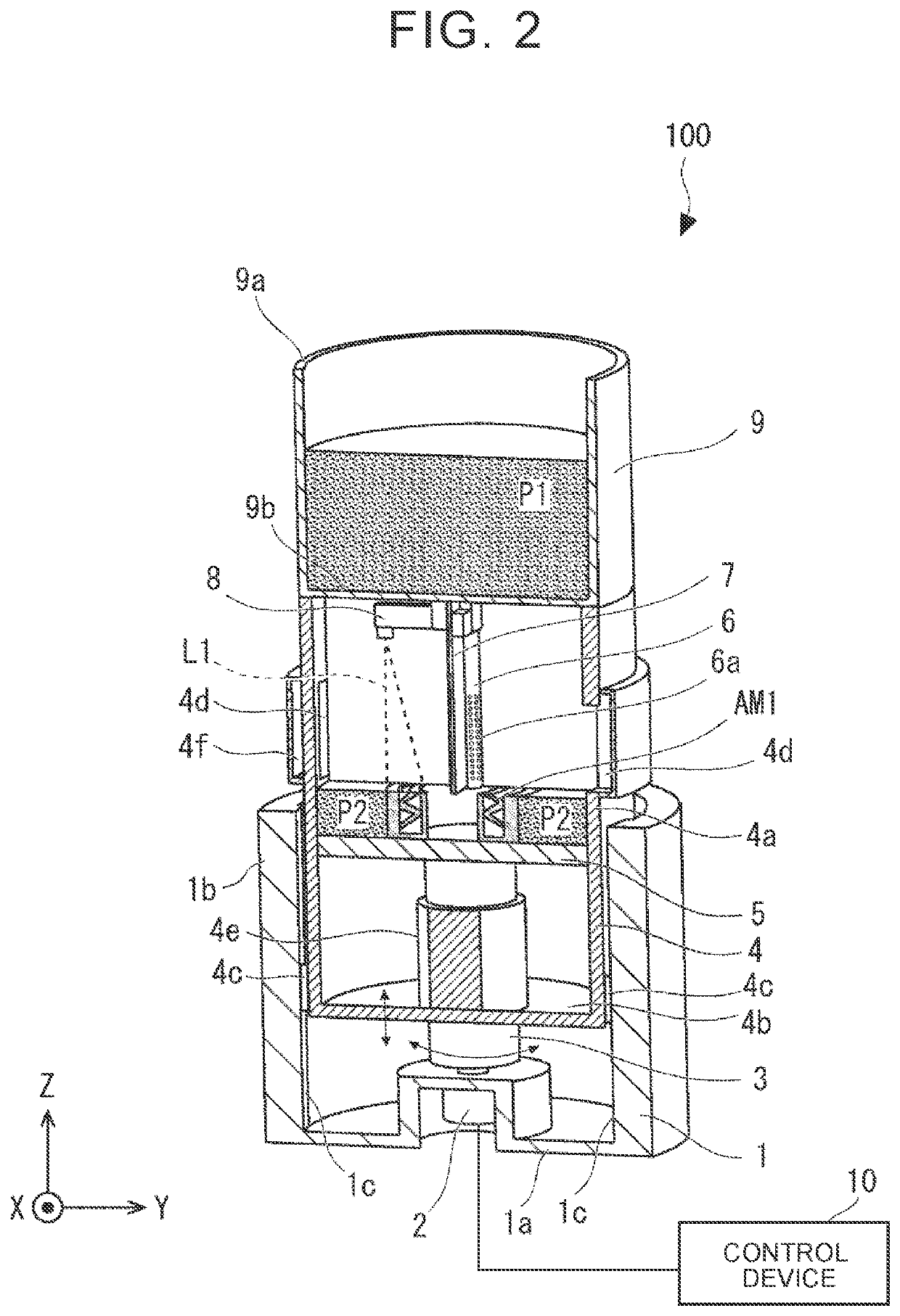

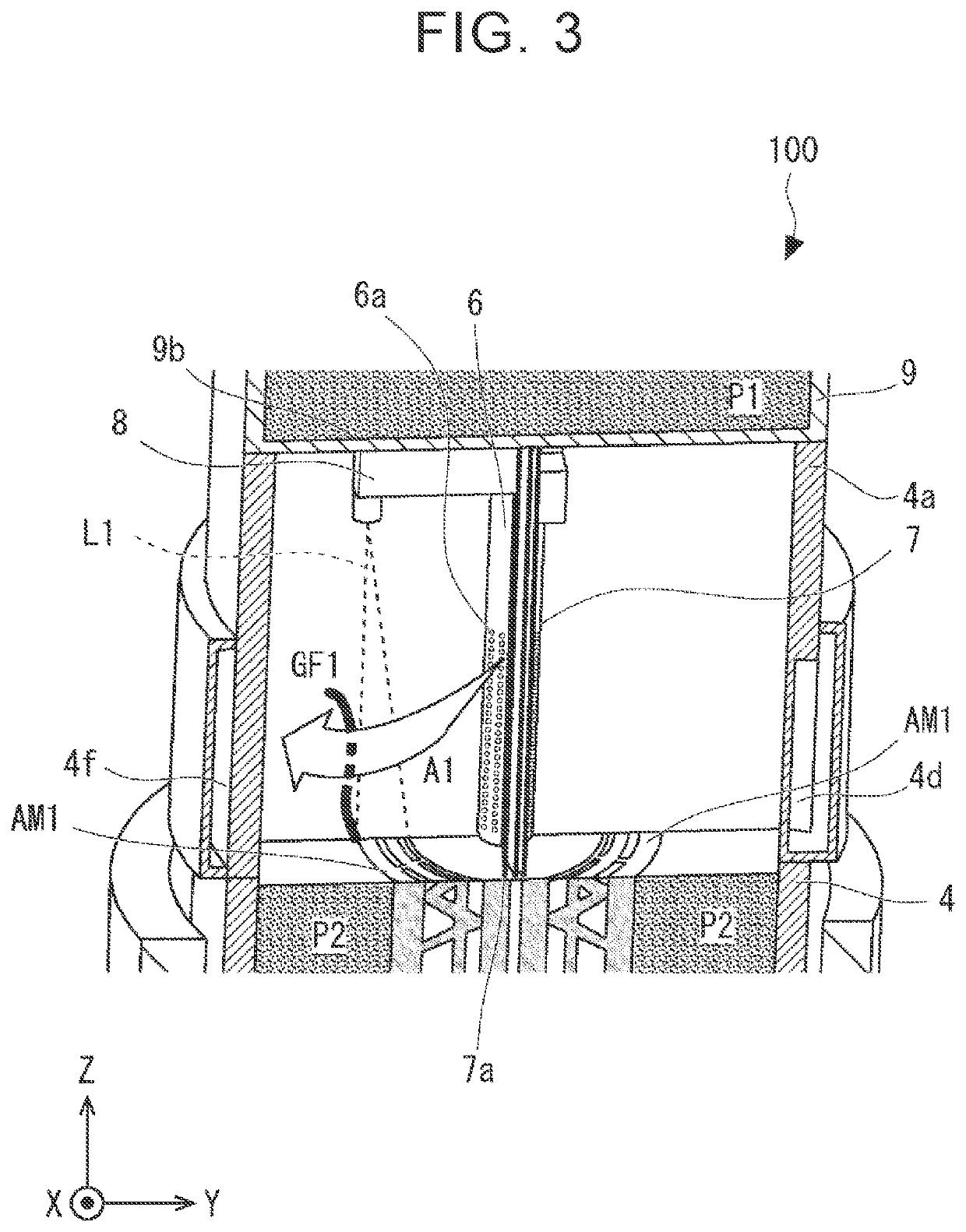

Laminate molding method and laminate molding apparatus

PendingUS20210394270A1Increase flow rateAvoid residueAdditive manufacturing apparatusIncreasing energy efficiencyMetal powderEnergy source

Provided is a laminate molding method for additionally manufacturing a molded object on a table by use of metal powder. The laminate molding method includes: a metal powder layer forming step of forming a metal powder layer by supplying metal powder onto a table; a melting step of melting the metal powder layer by applying, to the metal powder layer, electromagnetic energy emitted from an electromagnetic energy source; a rotating step of rotating the electromagnetic energy source and the table relative to each other; and a table vertically moving step of vertically moving the table relative to the electromagnetic energy source. Gas is emitted from a gas emission port toward an outer side of the table, the gas emission portion being provided in generally a center of the table.

Owner:TOYOTA JIDOSHA KK

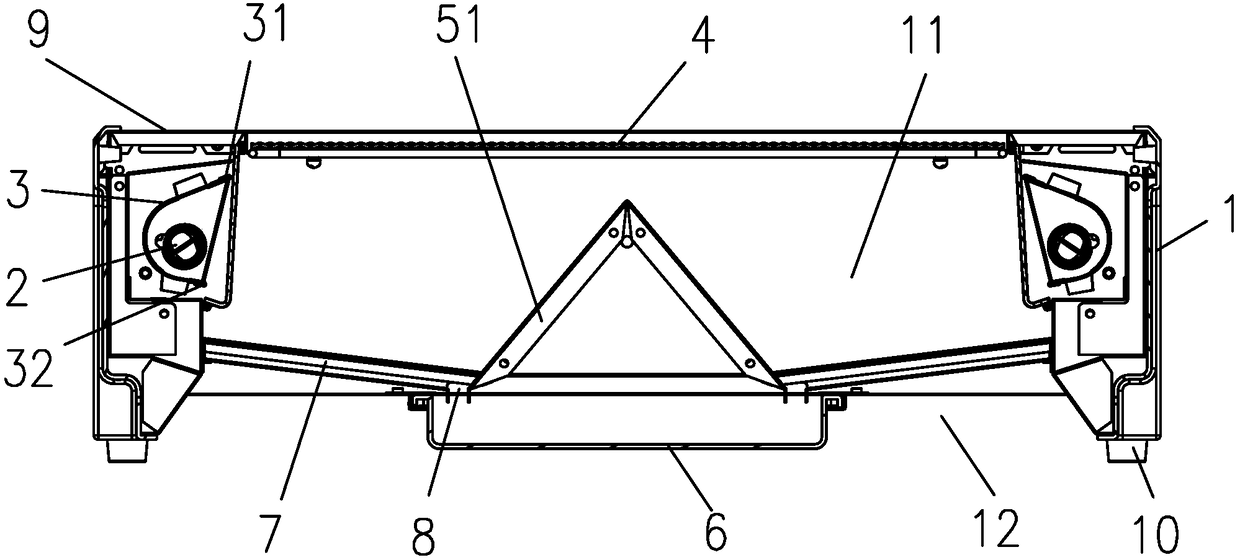

Smoke-free, non-stick environmental protection barbecue stove

The invention discloses a smokeless, non-stick, burnt-less and environment-friendly broiling furnace, which consists of a furnace body (2) arranged on a grate (1), wherein two sides of the furnace body (2) are provided with a hearth (3) respectively, a water tank (4) is arranged in the middle of the furnace body (2), a furnace cover (5) is arranged above the furnace body (2), and a broiling net (6) is arranged in the middle of the furnace cover (5). The broiling furnace is characterized in that the broiling net (6) consists of a sink (7) and metal pipes (8), the sink (7) is provided with a water filling opening (9), and the metal pipes (8) are arranged in lines at the bottom of the sink (7) and run through the sink (7) to form the tray broiling net (6). The broiling furnace has a simple structure and convenient use, adopts water to adjust the temperature, prevents phenomena of adhesion, singe and burnt, and ensures the edible safety.

Owner:王龙平

Novel electric heating barbecue oven

InactiveCN108618649AEvenly heatedAvoid insufficient heatingRoasters/grillsEngineeringElectric heating

The invention discloses a novel electric heating barbecue oven. The novel electric heating barbecue oven comprises a square or circular oven body and heating tubes arranged on the two sides of the oven body. A barbecue area is arranged on the oven body. Arc-shaped reflecting covers are arranged outside the heating tubes to surround the heating tubes from the backs of the heating tubes. An inverted-V-shaped reflecting plate or a conical reflector is arranged in the middle of the oven body, and is higher than the heating tubes. An oil receiving tray is located outside a heating reflecting cavity. The novel electric heating barbecue oven is simple in structure and low in cost, but the excellent barbecue effect can be achieved, foods in the barbecue area can be heated more uniformly, meanwhile, sinters and oily fume in the barbecue process can be effectively reduced, the using experience of a consumer is good, and the novel electric heating barbecue oven can be widely applied to various barbecue ovens.

Owner:江门市联晟五金电器有限公司

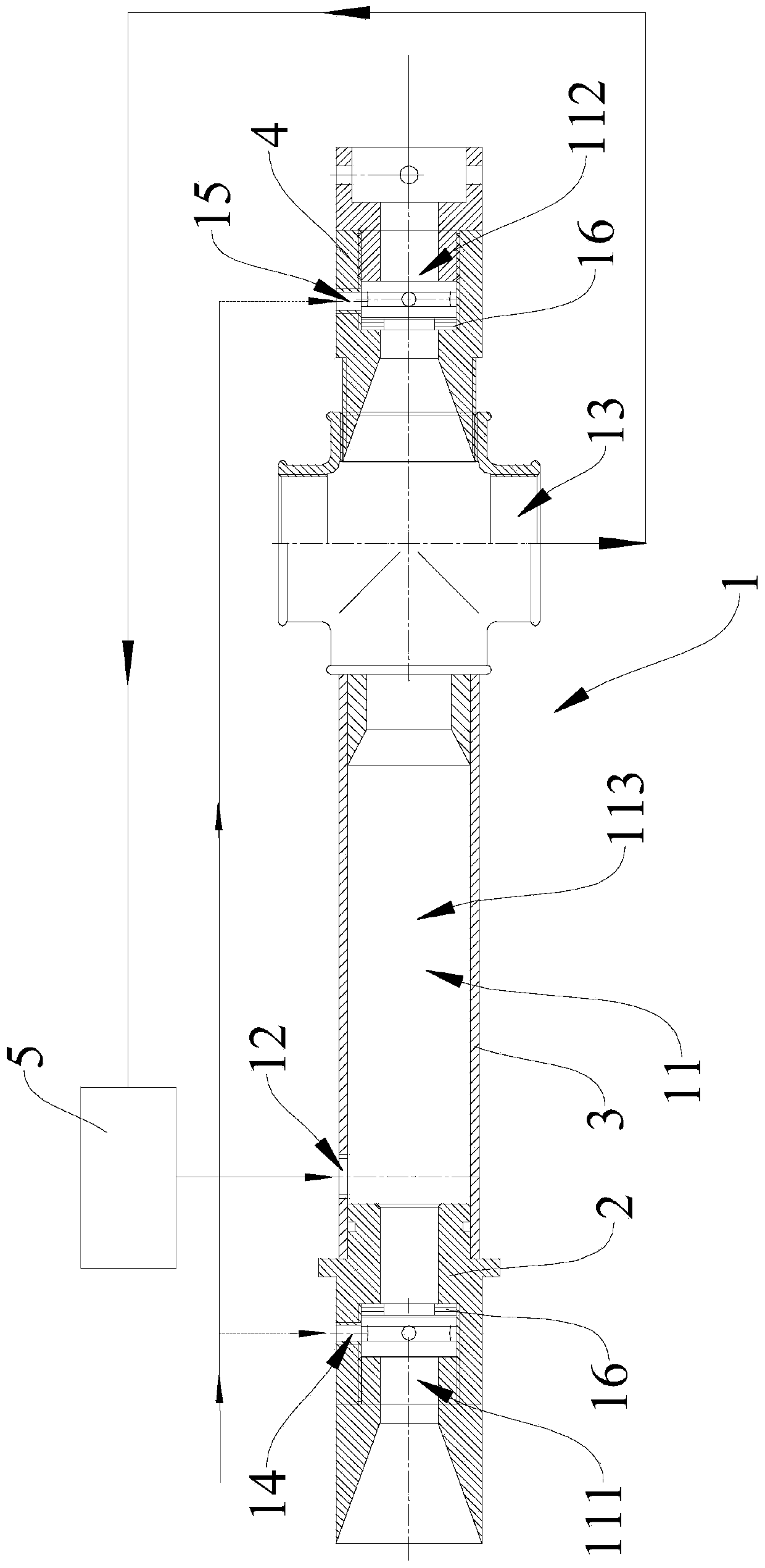

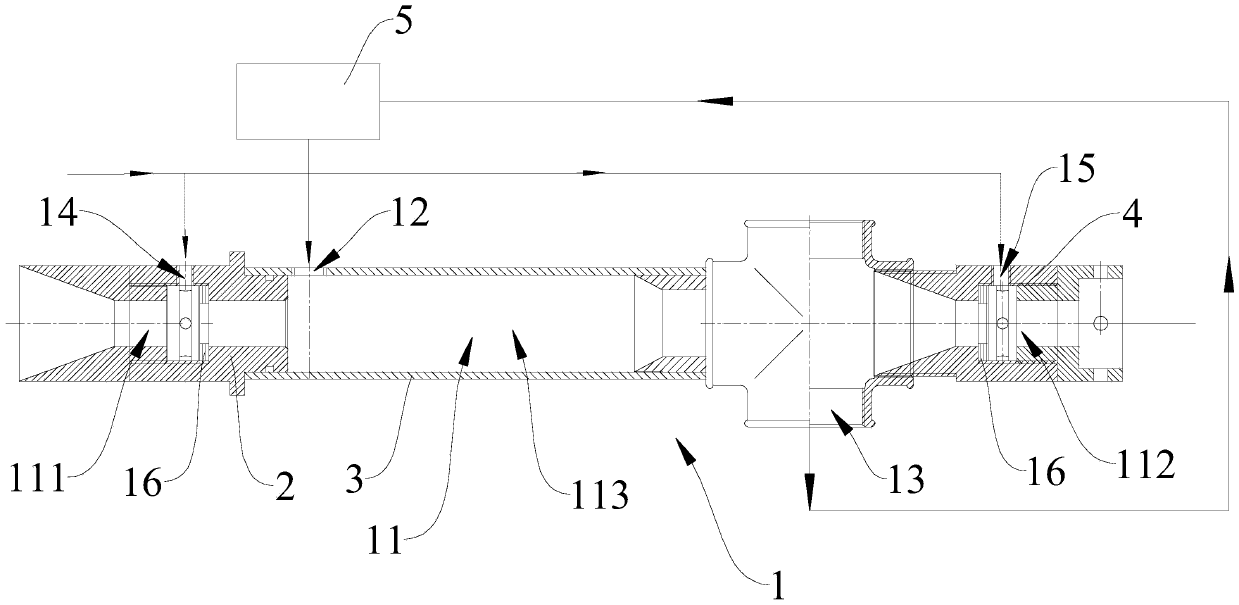

Copper pipe producing cooling device

The invention discloses a copper pipe producing cooling device. The copper pipe producing cooling device comprises a cooling pipe body, the cooling pipe body is provided with a cooling through hole allowing a copper pipe to penetrate in, the cooling through hole comprises a liquid cooling segment, a first air cooling segment and a second air cooling segment, wherein the first air cooling segment and the second air cooling segment are located on the two ends of the liquid cooling segment, a liquid inlet allowing cooling liquid to enter the liquid cooling segment and a liquid outlet allowing thecooling liquid in the liquid cooling segment to flow out are formed in the periphery of the cooling pipe body, a first air inlet enabling the first air cooling segment to communicate with the exterior and a second air inlet enabling the second air cooling segment to communicate with the exterior are formed in the periphery side of the cooling pipe body, the first air inlet and the second air inlet are connected with an air inlet pipe, and seal rings are arranged at the positions, between the liquid cooling segment and the first air inlet and between the liquid cooling segment and the second air inlet, in the cooling through hole. Through the copper pipe producing cooling device, the high-temperature copper pipe is subjected to liquid cooling and air cooling at the same time, meanwhile, the cooling liquid can be circularly used, and the cooling liquid cannot be leaked from the copper pipe producing cooling device.

Owner:江苏仓环铜业股份有限公司

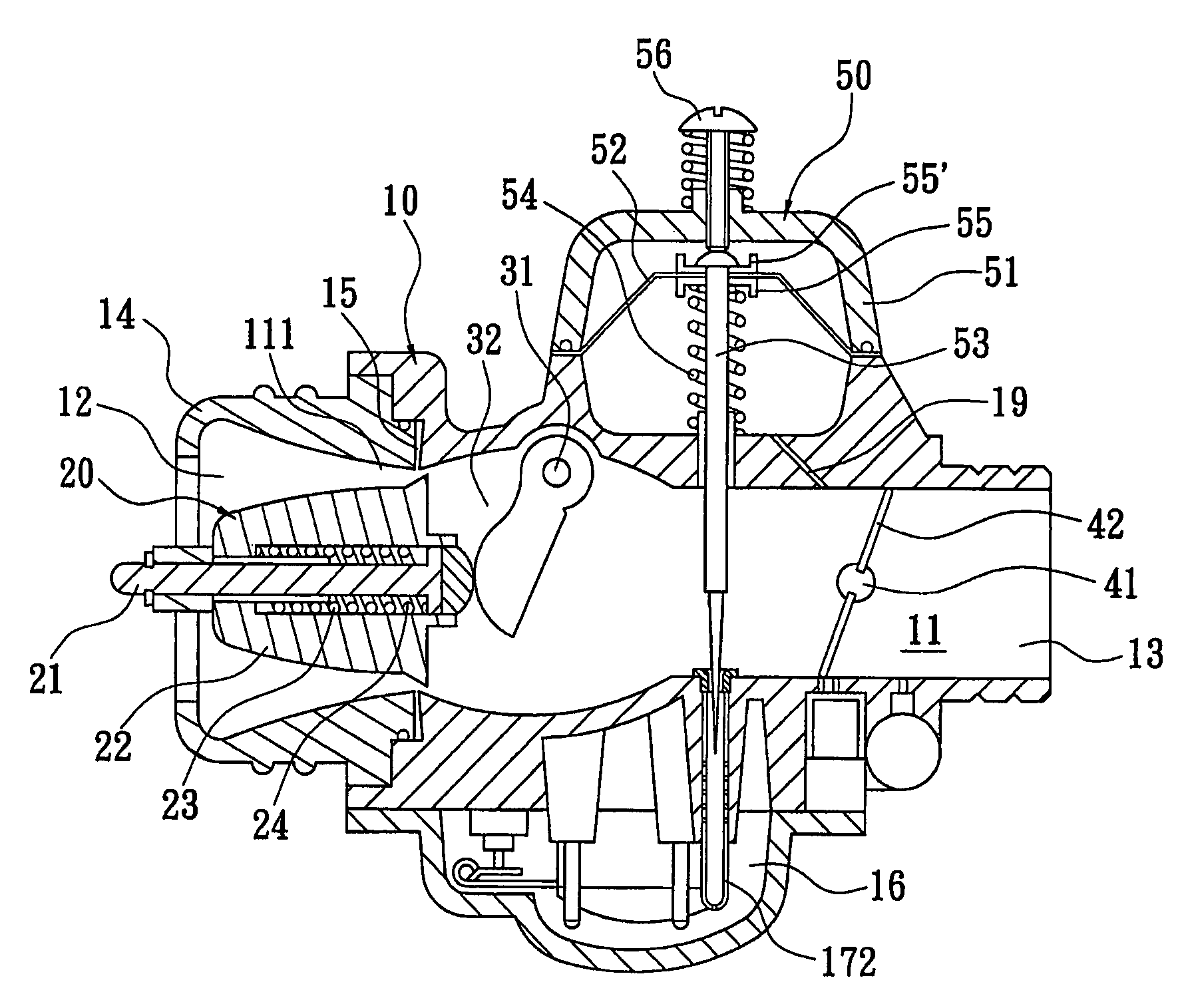

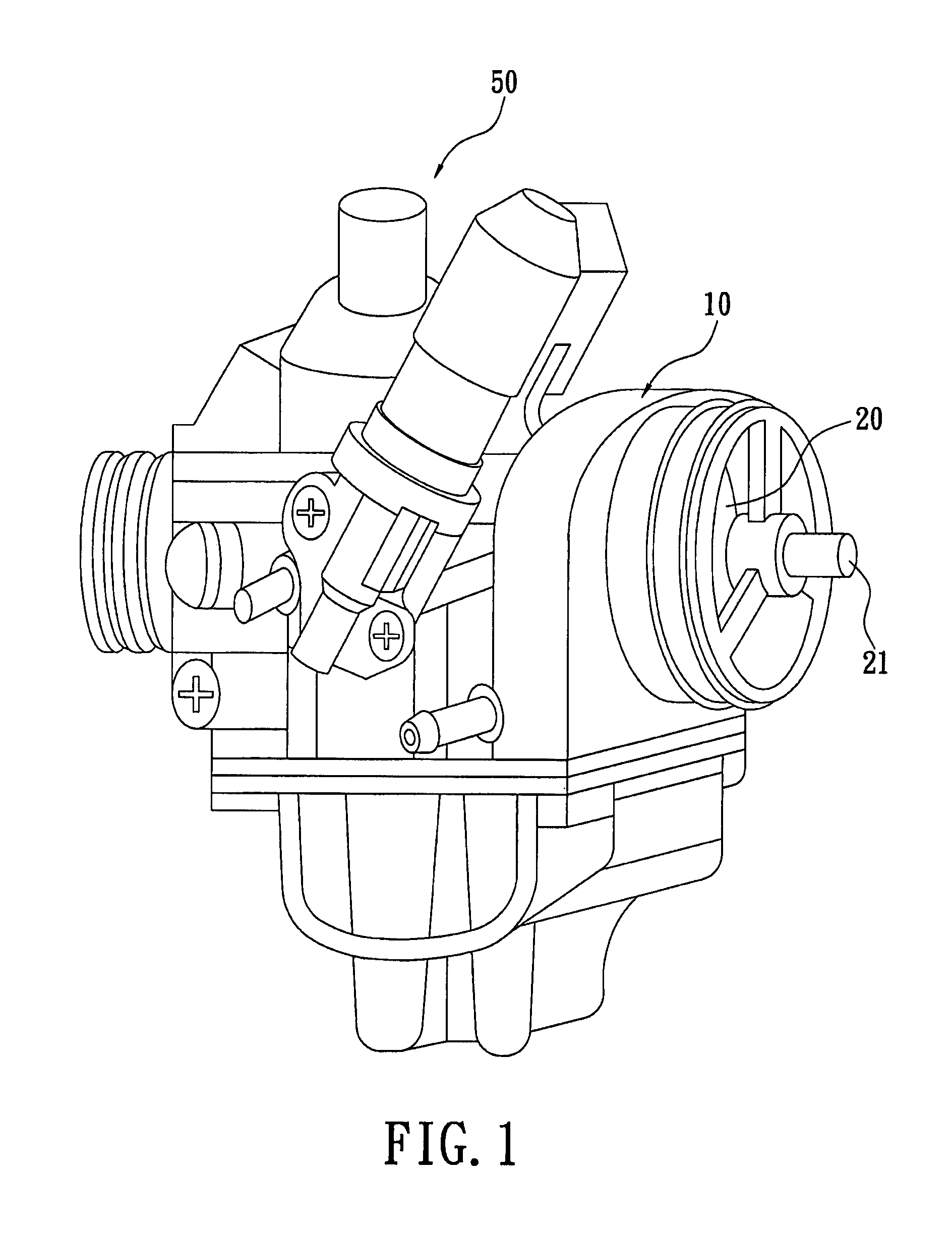

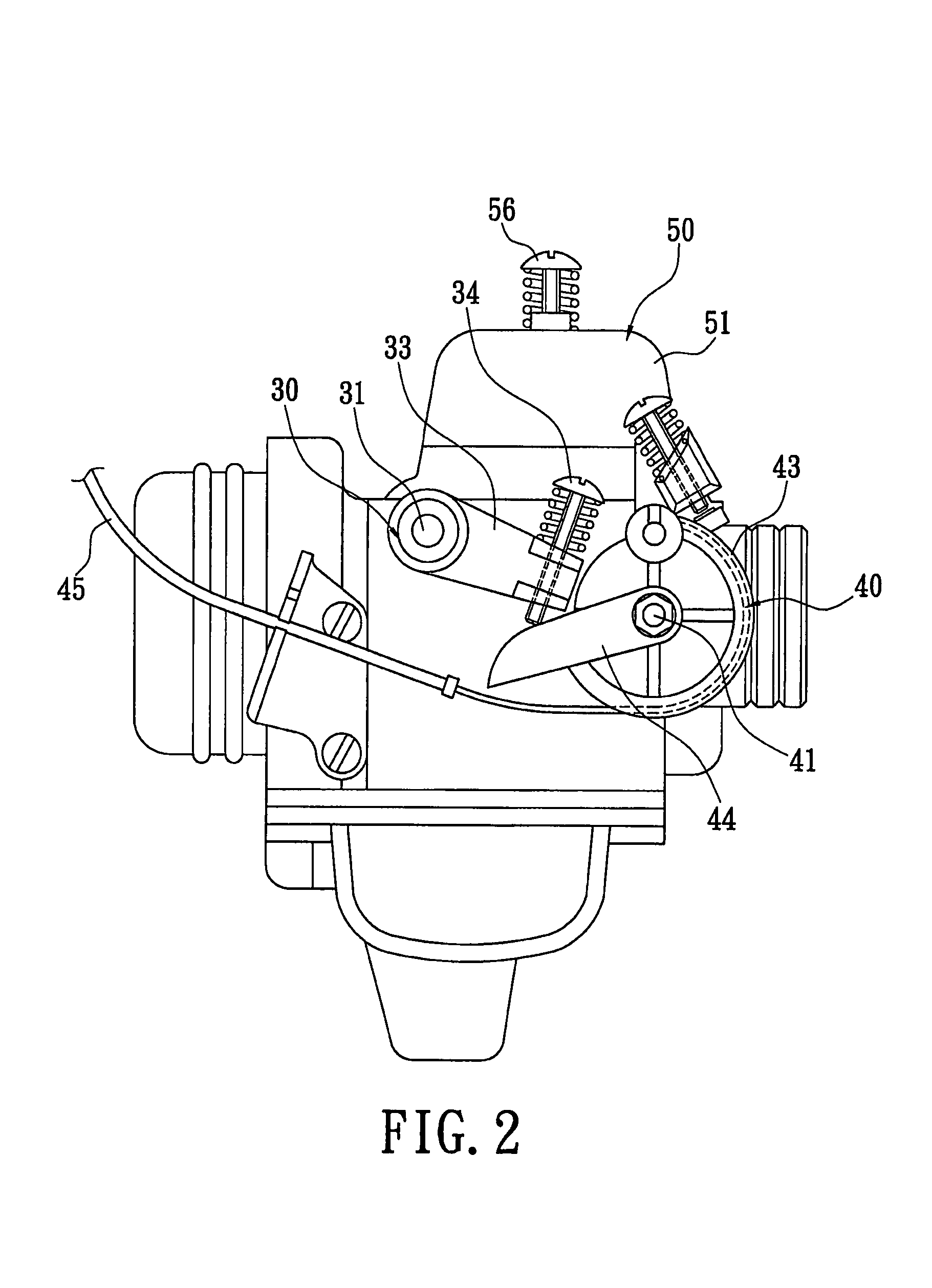

Carburetor

InactiveUS7441753B1Reduce pollutionImprove performanceLighting and heating apparatusMixing methodsCarburetorCam

A carburetor includes a base, a Venturi cone assembly, a cam assembly, a horsepower adjustment assembly, and a vacuum horsepower adjustment valve. The Venturi cone assembly is mounted in the base. A supporting portion of a cone collides with a cam of the cam assembly. An oil line rotation wheel of the horsepower adjustment assembly is drawn by an oiling line to drive the fan blade. The amount of displacement of the cone of the Venturi cone assembly under vacuum suction from the engine is controlled by a cam of the cam assembly. The vacuum horsepower adjustment valve automatically supplies enough fuel to the engine. Accordingly, the present invention can make the fuel burn sufficiently, effectively improving efficiency and reducing air pollution.

Owner:BORCH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com