Copper pipe producing cooling device

A cooling device and copper tube technology, applied in the field of copper tube production cooling devices, can solve the problems of easy heating and heating, threatening production safety, environmental pollution, etc., and achieve the effects of avoiding oil fume, good cooling effect, and improving workshop environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

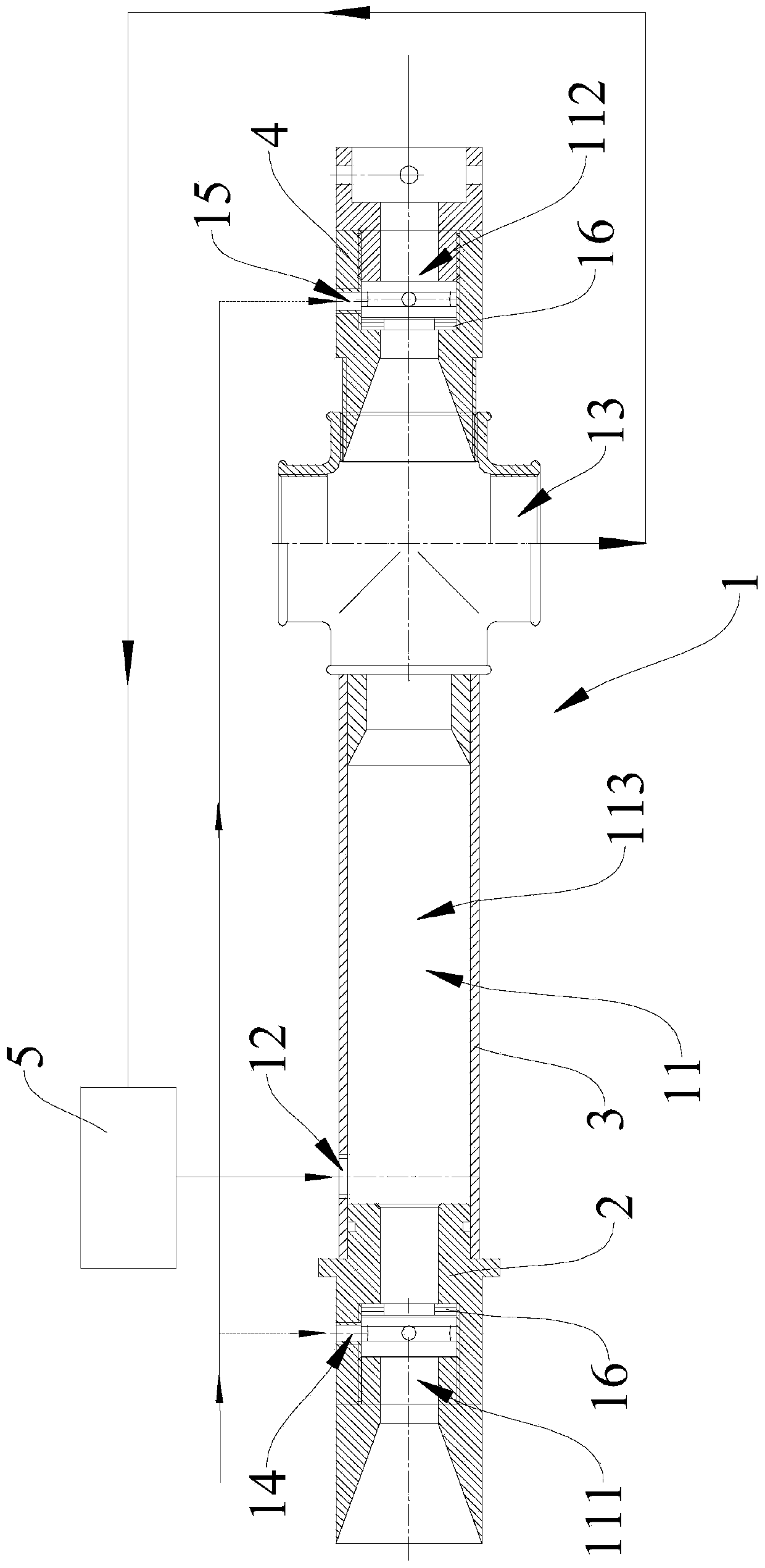

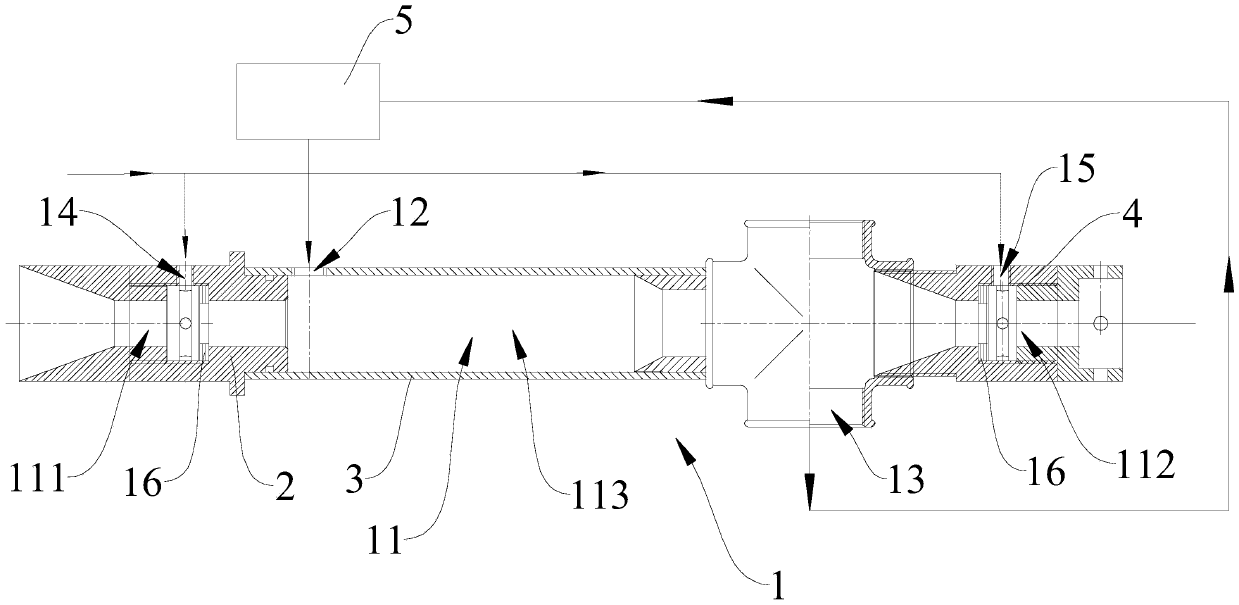

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] see figure 1 As shown, the copper pipe production cooling device includes a cooling pipe body 1, and the cooling pipe body has a cooling through hole 11 for the copper pipe to penetrate. The first air-cooled section 111 and the second air-cooled section 112, the peripheral side of the cooling pipe body 1 is provided with a liquid inlet 12 for the cooling liquid to enter the liquid-cooled section 113, and for the cooling liquid in the liquid-cooled section 113 to flow out The liquid outlet 13, the peripheral side of the cooling pipe body 1 is also provided with a first air inlet 14 that makes the first air-cooled section 111 communicate with the outside world, and a second air inlet that makes the second air-cooled section 112 communicate with the outside world 15. Both the first air inlet 14 and the second air inlet 15 are connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com