Structure of machine core of commercial induction cooker

A commercial induction cooker and core technology, applied in the field of induction cooker, can solve problems such as poor core control performance, solidified oil fume hardening of the core, equipment failure, etc., to achieve the effect of improving product performance, eliminating environmental oil fumes, and improving product service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

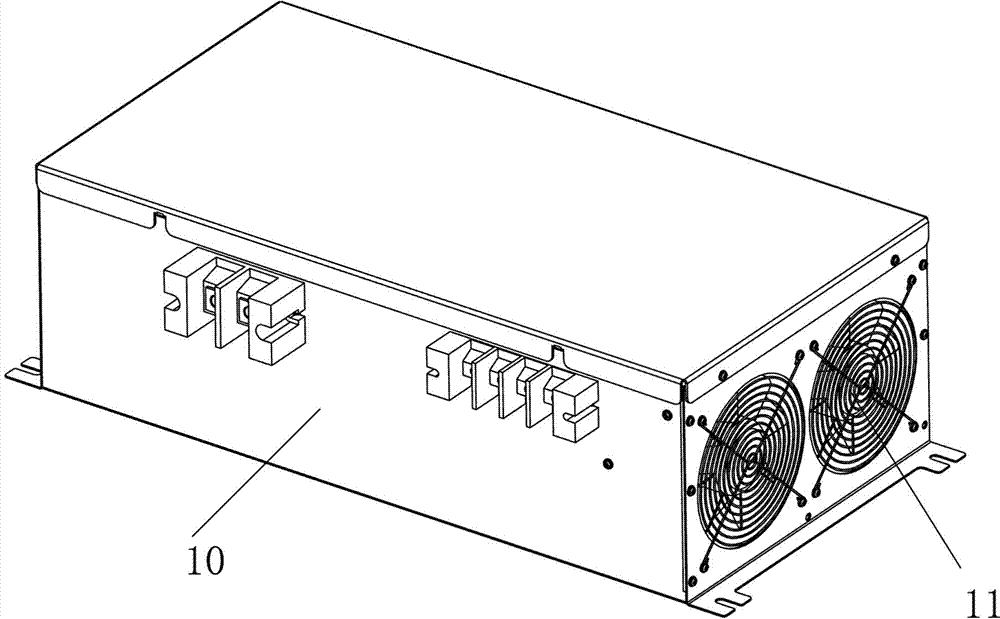

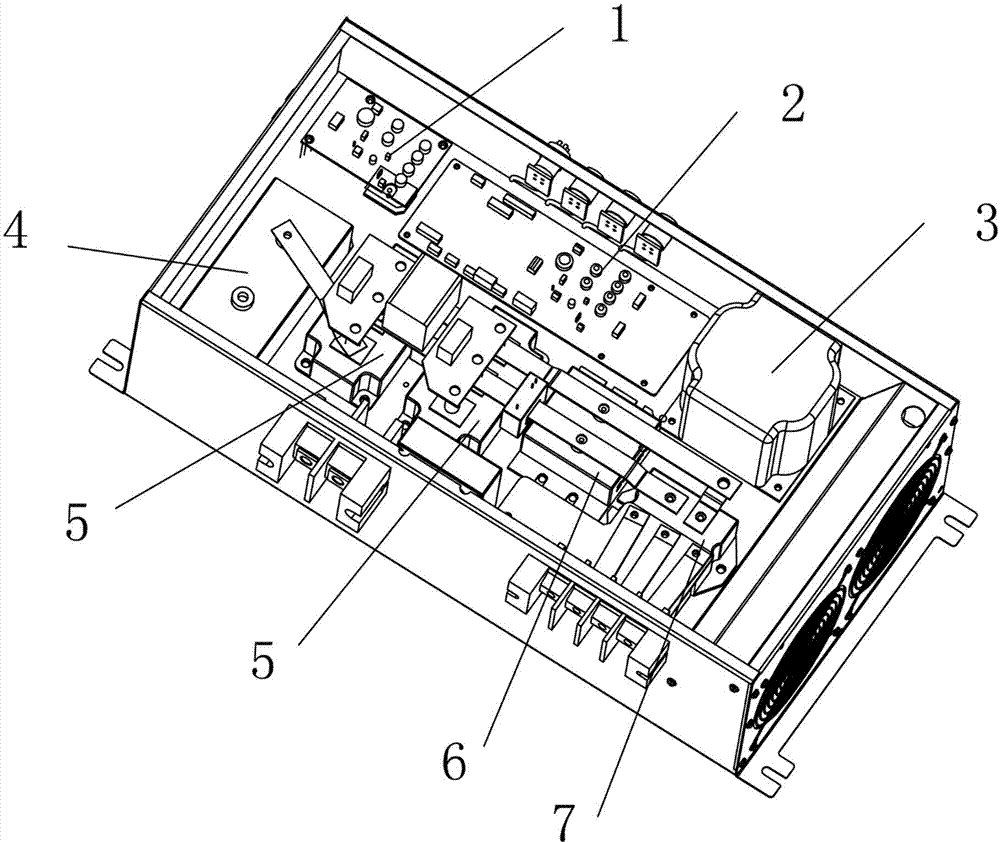

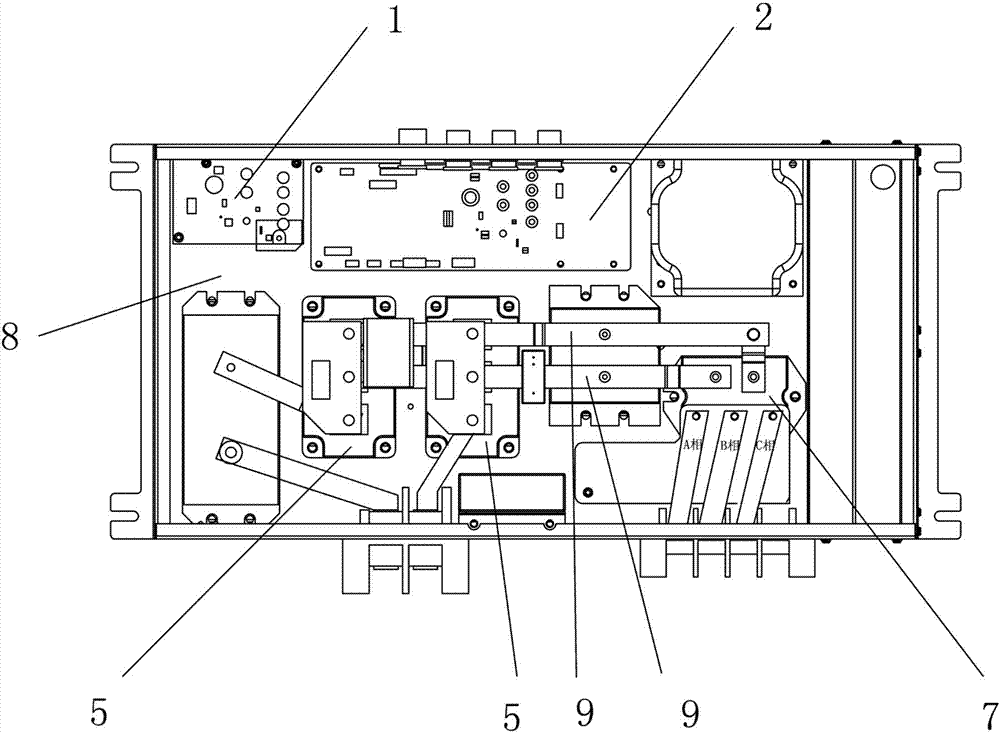

[0021] see Figure 1-5 , the present invention relates to a structure of a commercial induction cooker core, including a casing 10 and a strong electric unit and a weak electric unit fixed in the casing, an air inlet 12 and an air outlet 11 for heat dissipation provided on the casing, The casing is provided with a radiator 8 and a wind-blocking plate 14, the wind-blocking plate is connected to the radiator, and the two separate the casing 10 into upper and lower sections, the first section is a closed area, and the top is provided with a cover plate 15, The second interval is a heat dissipation area, and the strong electric unit and the weak electric unit are arranged in the first interval, and the components of the strong electric unit are installed close to the surface of the radiator 8; the working heat of the components of the strong electric unit p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com