Temperature-sensing device structure of electromagnetic heater

A technology of temperature sensor and induction cooker, applied in the field of induction cooker, can solve the problems of temperature increase, easy to burn out the wire plate under the microcrystalline plate, inability to accurately detect the heating temperature of the pot body, etc. burnout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

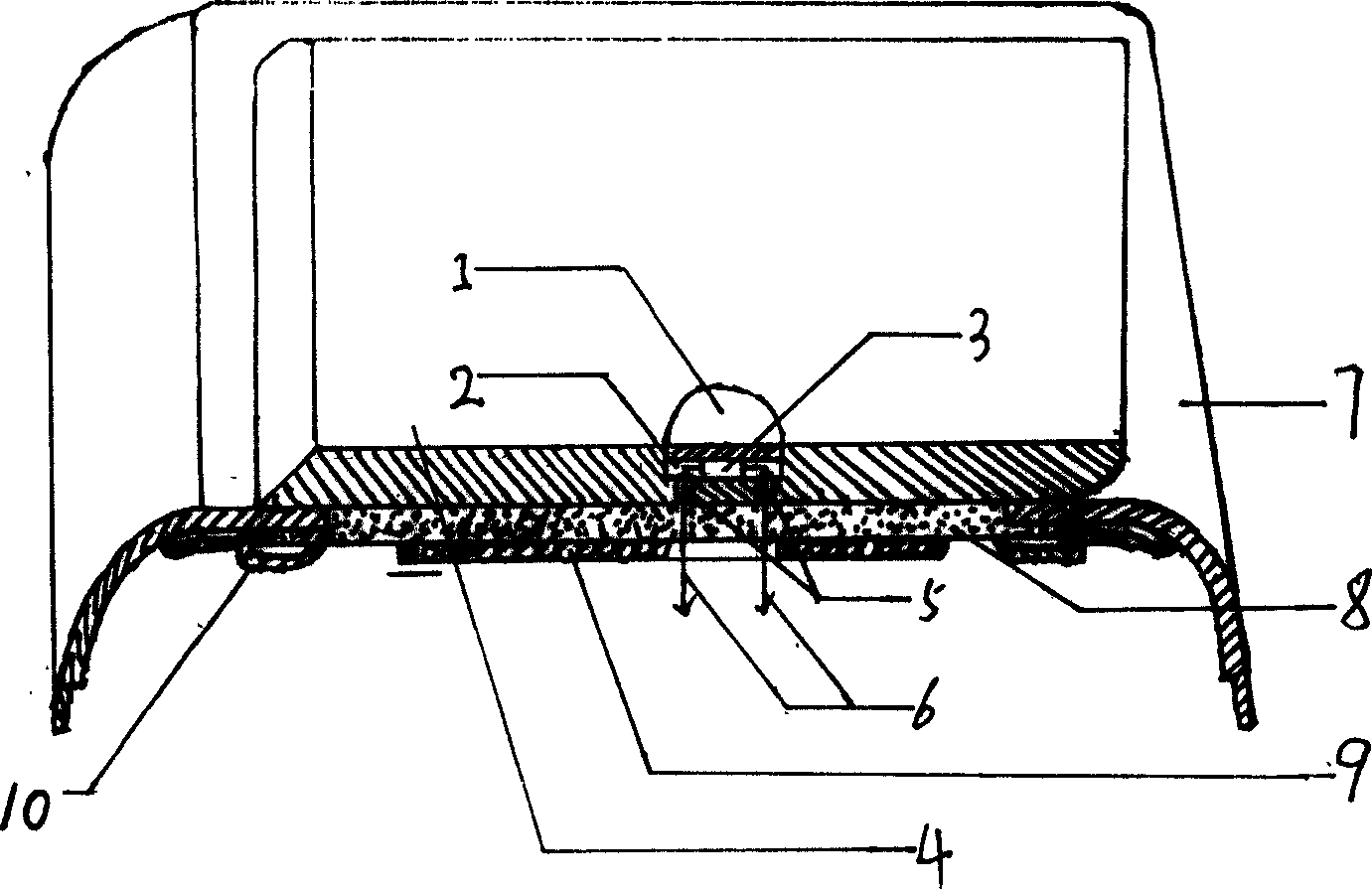

[0008] Below in conjunction with a preferred embodiment and accompanying drawing thereof, the present invention will be further described, see accompanying drawing 1 preferred embodiment of the present invention is to open a circular groove (2) at the microcrystalline plate (4) central position, in concave Drill two small holes (5) in the groove (2), put the thermistor (3) into the groove (2), the two feet of the thermistor (3) are led out through the small holes (5), use a The circular copper plate (1) is embedded in the circular groove (2), and is firmly glued to prevent water from entering, so that the surface of the copper plate (1) and the microcrystalline plate (4) are level, and the surface of the copper plate (1) and the thermistor (3) It forms a temperature sensor, where the copper plate (1) acts as a heat conductor. When working, the bottom of the stainless steel pot is in close contact with the copper plate (1), which can precisely control the temperature in the pot,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com