Method for preparing black titanium dioxide by contact type reduction method

A black titanium dioxide, titanium dioxide technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of difficult to achieve industrialization, high equipment investment costs, complex process conditions, etc. Low requirements and good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

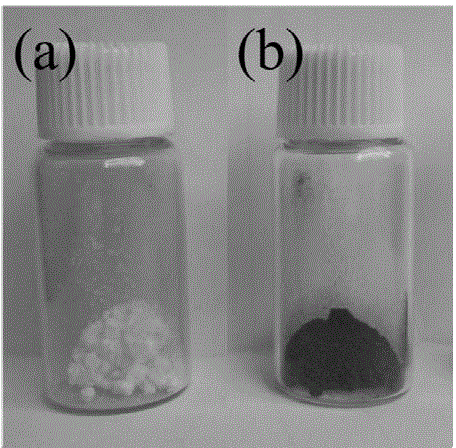

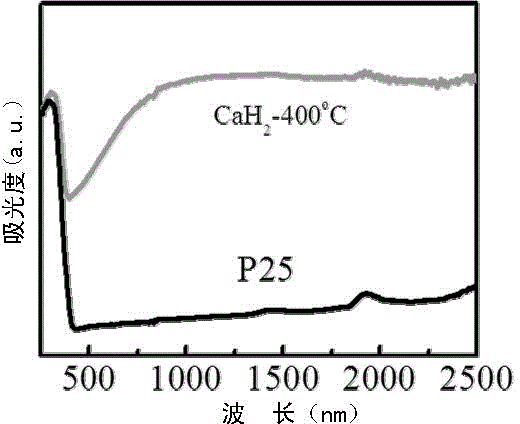

[0057] Commercial titanium dioxide (Degussa P25TiO 2 ) as the raw material, calcium hydride as a highly active reducing agent, mixed and ground into the quartz tube, vacuumed to make the pressure inside the quartz tube less than 100Pa, sealed the quartz tube, and put it in a furnace at 400°C for 5 hours, then turned off the heating power, and waited The samples were taken out after cooling naturally in the furnace. The obtained powder was added into 1mol / L hydrochloric acid solution and stirred and pickled for 6 hours to remove residual calcium hydride and calcium oxide, then washed with deionized water until neutral, filtered, and baked at 80°C for 12 hours to obtain black nano titanium dioxide.

[0058] After reduction treatment, the sample turns from white to black, and the absorption spectrum is as follows: figure 2 As shown, the absorption of the treated sample in the visible and infrared regions increased significantly, indicating that the photoresponse range of the sa...

Embodiment 2

[0063] Titanium dioxide nanowires made by hydrothermal method as raw materials (Yin, H.; Ding, G.Q.; Gao, B.; Huang, F.Q.; Xie, X.M.; Jiang, M.H., Mater Res Bull2012, 47(11), 3124-3128 .), metal aluminum is a highly active reducing agent, put it into a quartz tube after mixing and grinding, vacuumize the pressure inside the quartz tube to 50Pa, seal the quartz tube, and put it in a furnace at 700°C for 8 hours, then turn off the heating power, and wait for the sample Take it out after cooling naturally with the furnace. The obtained powder was added into 1 mol / L hydrochloric acid solution and stirred and pickled for 6 hours to remove residual metal aluminum and produced alumina, then washed with deionized water until neutral, filtered, and baked at 80°C for 12 hours to obtain black titanium dioxide nanowires.

[0064] After the reduction treatment, the sample changed from white to black, and the absorption spectrum test showed that the absorption of the treated sample in the v...

Embodiment 3

[0068] The titanium dioxide nanowire array made by anodic oxidation is used as the raw material, and sodium borohydride is used as a highly active reducing agent. The nanowire array is buried in sodium borohydride powder, put into a quartz tube, and the pressure inside the quartz tube is evacuated to 10Pa, and the quartz tube is sealed. dead, and placed in a furnace at 200°C for 72 hours to react, then turn off the heating power, and take out the sample after cooling naturally with the furnace. The surface powder is blown off to obtain a black titanium dioxide nanowire array.

[0069] After the reduction treatment, the sample changed from khaki to black, and the absorption spectrum test showed that the absorption of the treated sample in the visible and infrared regions increased significantly; it showed that the photoresponse range of the sample after the reduction treatment was greatly broadened, and there were high levels in the visible and infrared regions. Absorption.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com