Non-contact printed comestible products and apparatus and method for producing same

A technology of equipment and printing machine, which is applied to non-contact printing of food and its production equipment and production fields, can solve the problems of time, money and manpower consumption, and achieve the effect of increasing stimulation and happiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

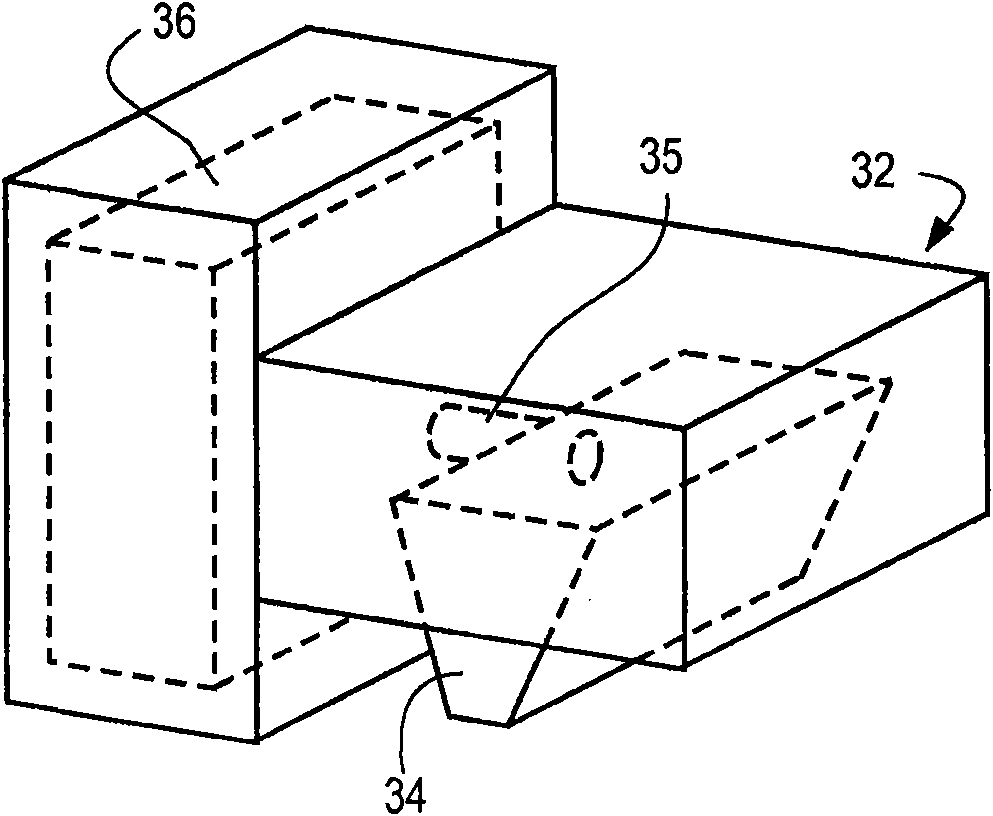

[0088] Refer generally to the drawings, in which like reference numerals indicate similar structures and elements, and in particular figure 1 , Showing a perspective view of a printer 32 for printing on an edible substrate. It should be understood that an "edible" product or "edible" substrate is a composition suitable for consumption and non-toxic. The edible substrate may also be a material that meets applicable standards such as the Food, Drug, and Cosmetic (FD&C) regulations of the United States and / or the European Control (Eurocontro1) Test Center (E.E.C.) standard of Euslaban Union. Non-limiting examples of suitable edible substrates include confectionery materials, batters, puffed foods such as biscuits and potato chips, marshmallows, flour pastries, pet foods, cereals, sausages, and cheeses.

[0089] In one embodiment, the edible substrate may be an edible substrate with a coating, an edible substrate without a coating, an edible substrate with a curved surface profile, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com