Dual-layer-coated nanometer silicon negative electrode material and preparation method and application thereof

A negative electrode material and double-layer coating technology, which is applied in the field of double-layer composite-coated nano-silicon negative electrode material and its preparation, can solve problems such as the negative impact of material cycle performance, achieve excellent electrochemical performance, increase conductivity, inhibit The effect of volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Weigh 0.5g of silicon powder with a particle size of 100nm and put it into 1000ml of water, then add 20ml of ethanol to obtain a nano-silicon suspension, and then place the nano-silicon suspension in an ultrasonic machine for ultrasonication for 2 hours;

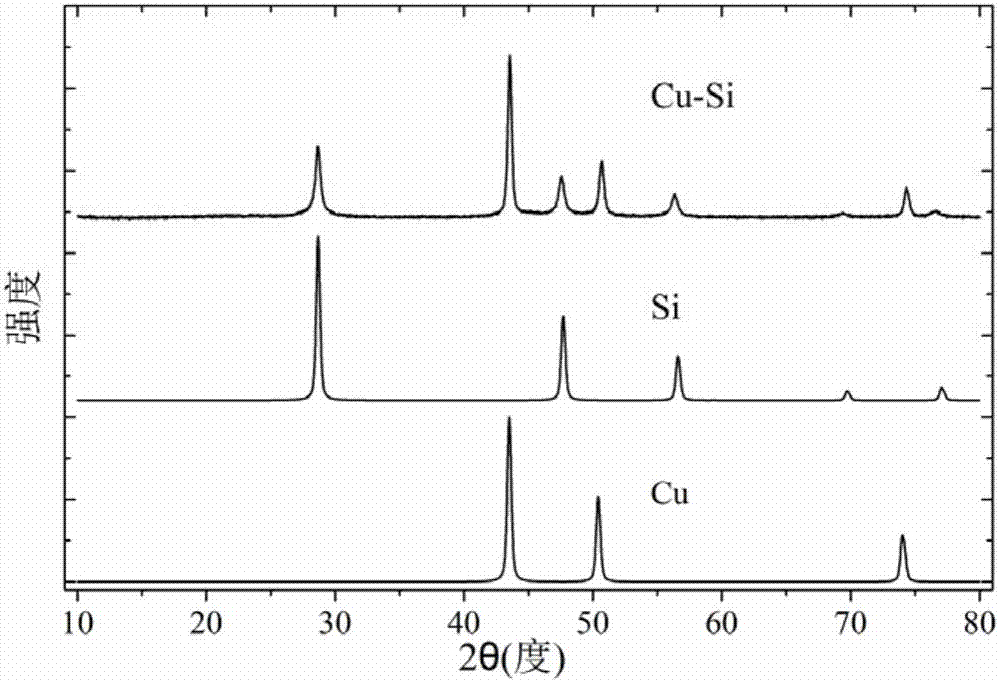

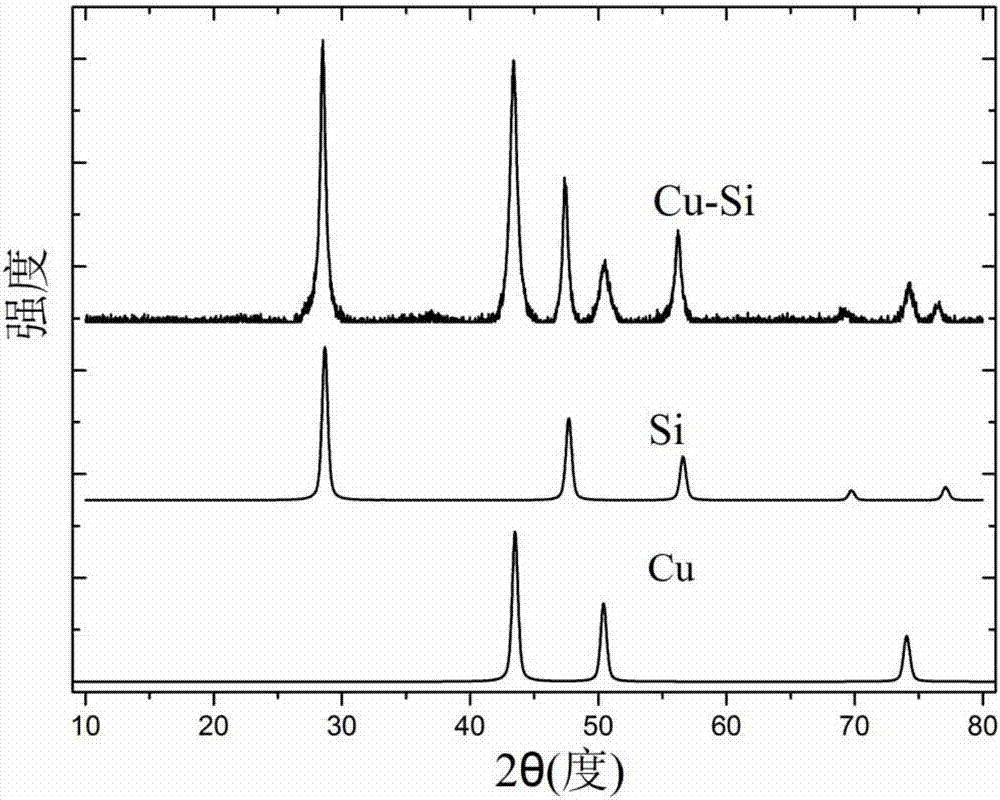

[0045] (2) The ultrasonically dispersed nano-silicon suspension is continuously stirred with a magnetic stirrer, and nitrogen gas is continuously introduced into the solution at the same time. Then add the following copper plating agent in the solution: 1g CuSO 4 , 10 g of potassium sodium tartrate, 10 g of ethylenediamine tetraacetic acid and 5 mg of 2,2-bipyridine, and then adding sodium hydroxide to adjust the pH to 10. Then add 0.6g of sodium borohydride to 200ml of water, and add sodium hydroxide to adjust the pH to 10, then drop it into the nano-silicon suspension at a rate of about 30 drops / min, and finally filter and add copper protective agent to wash 1. Obtain nano-silicon composite material coated with...

Embodiment 2

[0048] (1) Weigh 0.5g of 100nm silicon powder and put it into 1000ml of water, then add a small amount of 20ml of ethanol to obtain a nano-silicon suspension, and then place the nano-silicon suspension in an ultrasonic machine for ultrasonication for 2 hours;

[0049] (2) The ultrasonically dispersed nano-silicon suspension is continuously stirred with a magnetic stirrer, and nitrogen gas is continuously introduced into the solution at the same time. Then add the following copper plating agent in the solution: 1g CuSO 4 , 10 g of potassium sodium tartrate, 10 g of ethylenediamine tetraacetic acid and 5 mg of 2,2-bipyridine, and then adding sodium hydroxide to adjust the pH to 10. Then add 0.6g of sodium borohydride to 200ml of water, and add sodium hydroxide to adjust the pH to 10, and then drop it into the nano-silicon solution at a speed of about 30 drops / min, and finally filter, add copper protective agent to wash, vacuum Obtain the nano-silicon composite material coated w...

Embodiment 3

[0053] (1) Weigh 0.5g of silicon powder with a particle size of 100nm and put it into 1000ml of water, then add 20ml of ethanol to obtain a nano-silicon suspension, and then place the nano-silicon suspension in an ultrasonic machine for ultrasonication for 2 hours;

[0054] (2) The ultrasonically dispersed nano-silicon suspension is continuously stirred with a magnetic stirrer, and nitrogen gas is continuously introduced into the solution at the same time. Then add the following copper plating agent in the solution: 1g CuSO 4 , 10 g of potassium sodium tartrate, 10 g of ethylenediamine tetraacetic acid and 5 mg of 2,2-bipyridine, and then adding sodium hydroxide to adjust the pH to 10. Then add 0.6g of sodium borohydride to 200ml of water, and add sodium hydroxide to adjust the pH to 10, then drop it into the nano-silicon suspension at a rate of about 30 drops / min, and finally filter and add copper protective agent to wash 1. Obtain nano-silicon composite material coated with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com