Method for preparing diamond enhanced copper based composite with high volume fraction

A copper-based composite material and diamond reinforced technology, applied in the field of metal-based composite materials, can solve the problems of poor wettability and insufficient bonding strength, and achieve the effects of improving thermal conductivity, avoiding interfacial thermal resistance and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

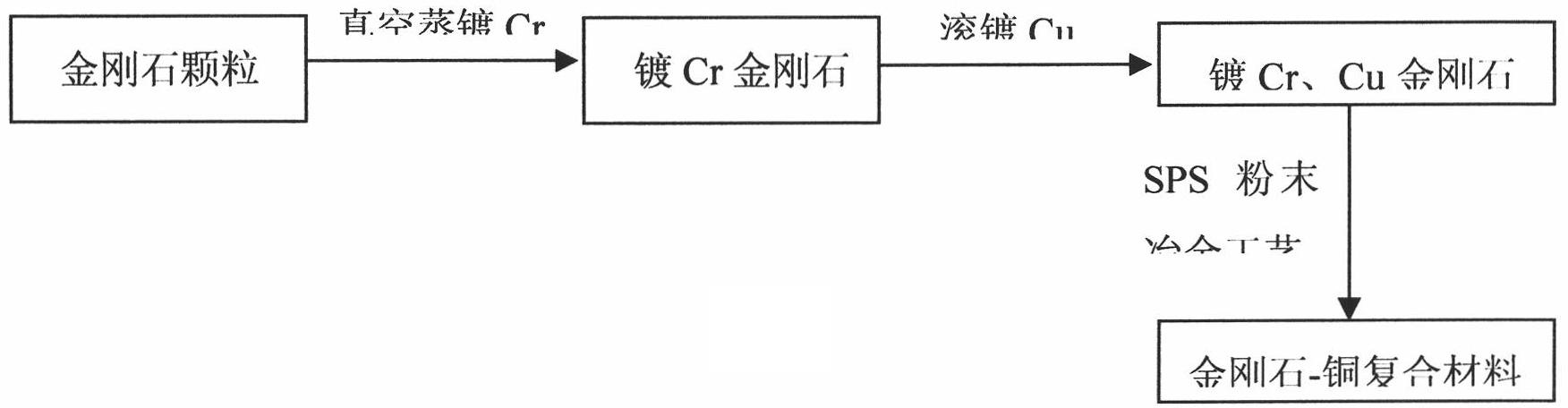

Method used

Image

Examples

Embodiment 1

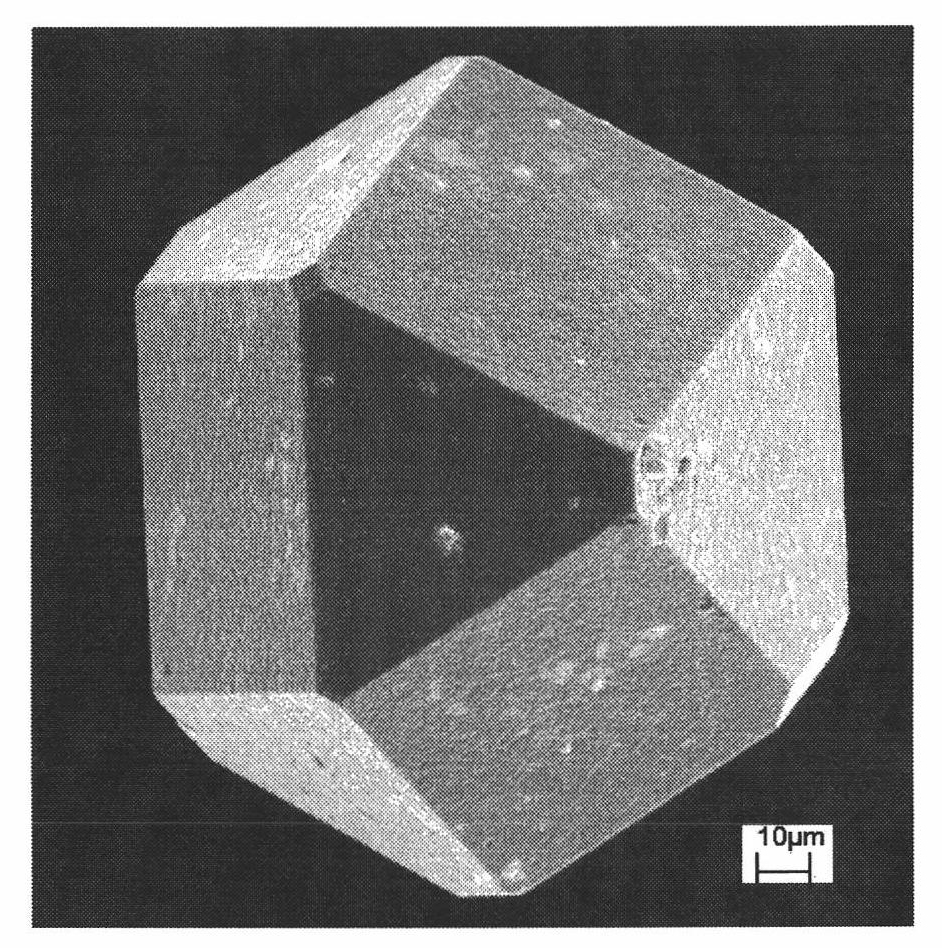

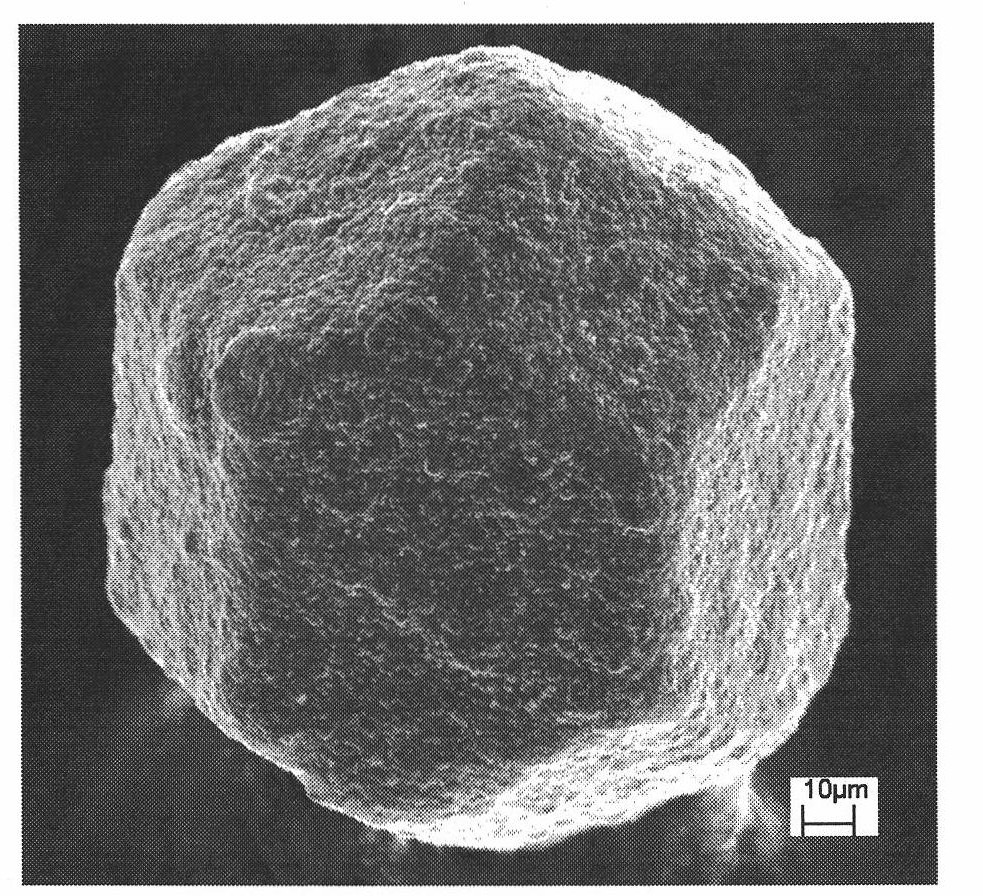

[0013] Diamonds with a particle size of 125 μm are selected for purification treatment, and a 1 μm thick Cr layer is plated on the diamond surface by vacuum evaporation, and then the Cr-plated diamonds are placed in the drum for copper element barrel plating to thicken, and the diamond after barrel plating The thickness of the copper coating on the surface is 20 μm, and the weight gain of the diamond is 169%; put the barrel-plated diamond into a plasma sintering furnace (SPS) for sintering to obtain a diamond-copper composite material; the sintering temperature is 925°C, and the sintering pressure is 50MPa , the heating rate is 30°C / min, the heat preservation is 10min, and the atmosphere is vacuum. The density of the diamond-copper composite material prepared by this process is 98%, and the thermal conductivity reaches 505W / (m·K).

Embodiment 2

[0015] The process conditions of this embodiment are the same as those of Example 1, except that the average particle size of the added diamond is changed, and the average particle size of the diamond used is 212 μm. The compactness of the prepared diamond-reinforced copper-based composite material is 95%, and the thermal conductivity is 475W / (m·K).

Embodiment 3

[0017] The process conditions of this embodiment are the same as those of Example 1, except that the average particle size of the added diamond is changed, and the average particle size of the diamond used is 75 μm. The compactness of the prepared diamond-reinforced copper-based composite material is 98%, and the thermal conductivity is 450W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com