Plastic electronic component package

a technology of electronic components and plastics, applied in the direction of transportation and packaging, basic electric elements, mechanical equipment, etc., can solve the problems of difficult to accurately align the glass cover to the ceramic frame, the ceramic package is expensive, and the ceramic package is not readily adapted to strip or other multiple unit manufacturing,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

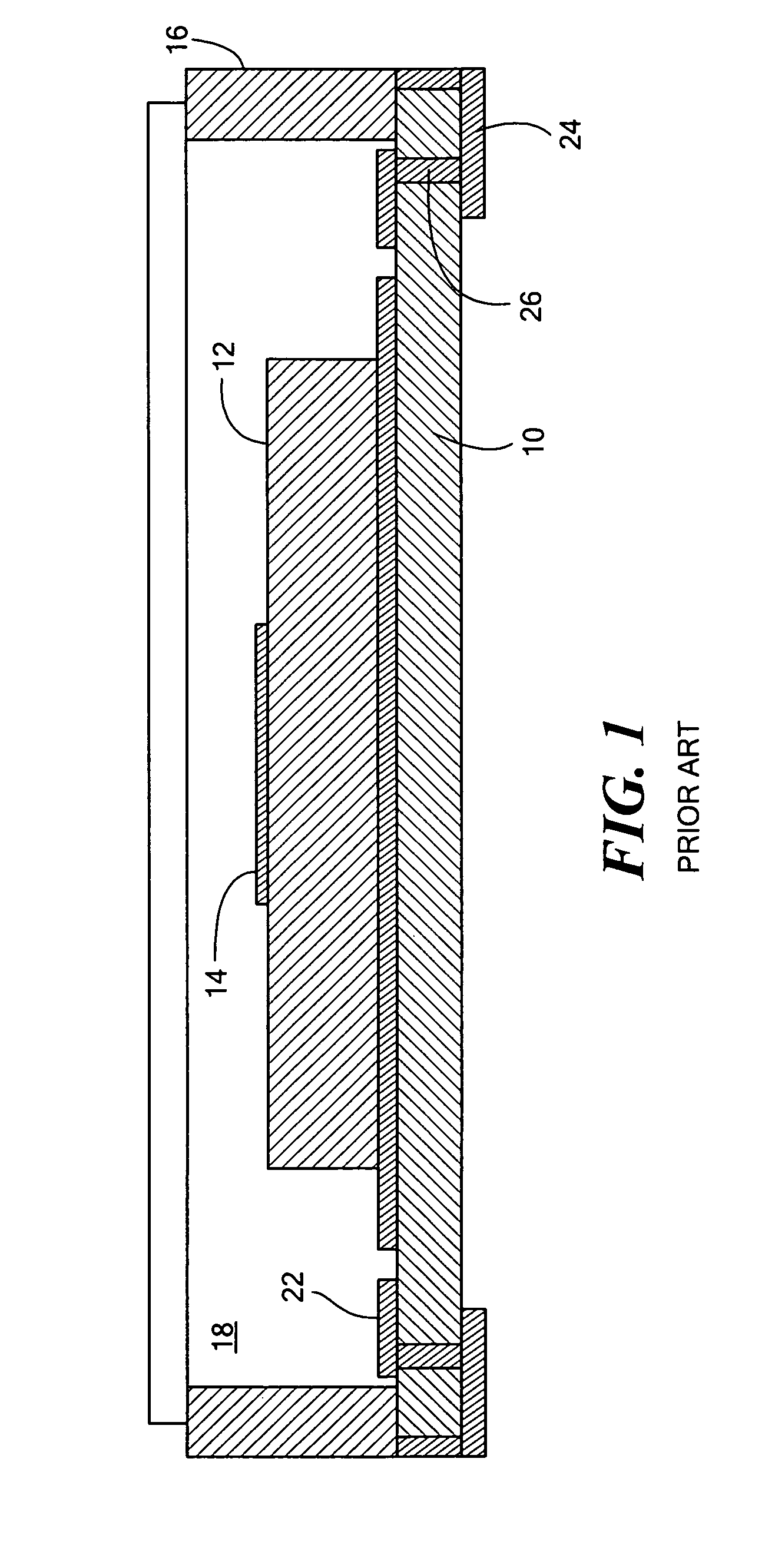

[0027]The package, materials and method of package fabrication are described in a preferred embodiment for an image sensor. The invention is not to be limited to image sensor packages or packages for other optical devices, but is more broadly useful for housing other semiconductor, electrical and electronic devices, components or circuits.

[0028]The package configuration can be of various forms to suit particular packaging requirements. The package configuration may vary in size and shape and can include electrical lead configurations of many different forms. The invention is not to be limited to any particular package type or configuration. The invention will be described in the context of a package for a semiconductor image sensor chip such as used in digital cameras and other digital imaging systems and devices.

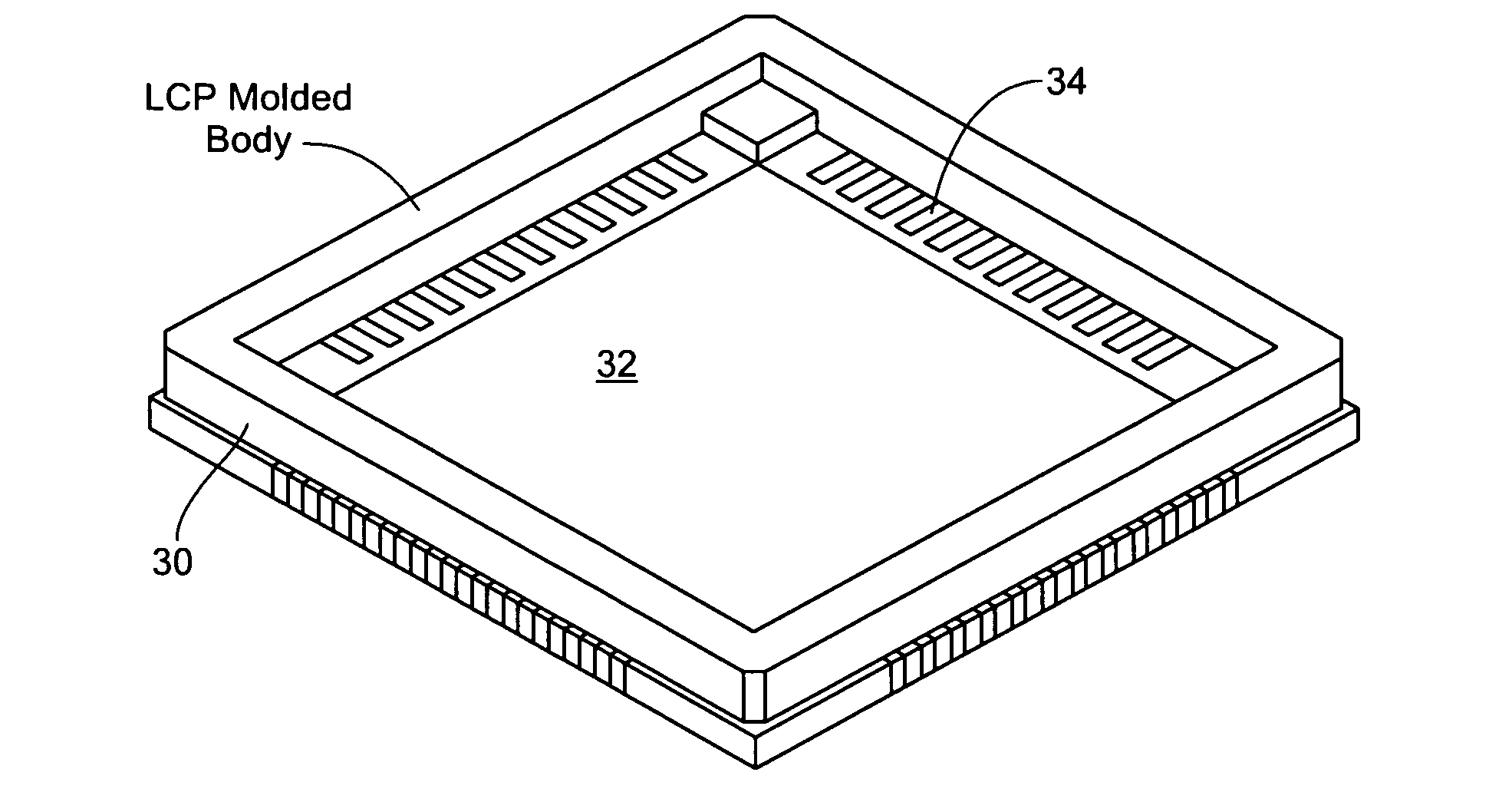

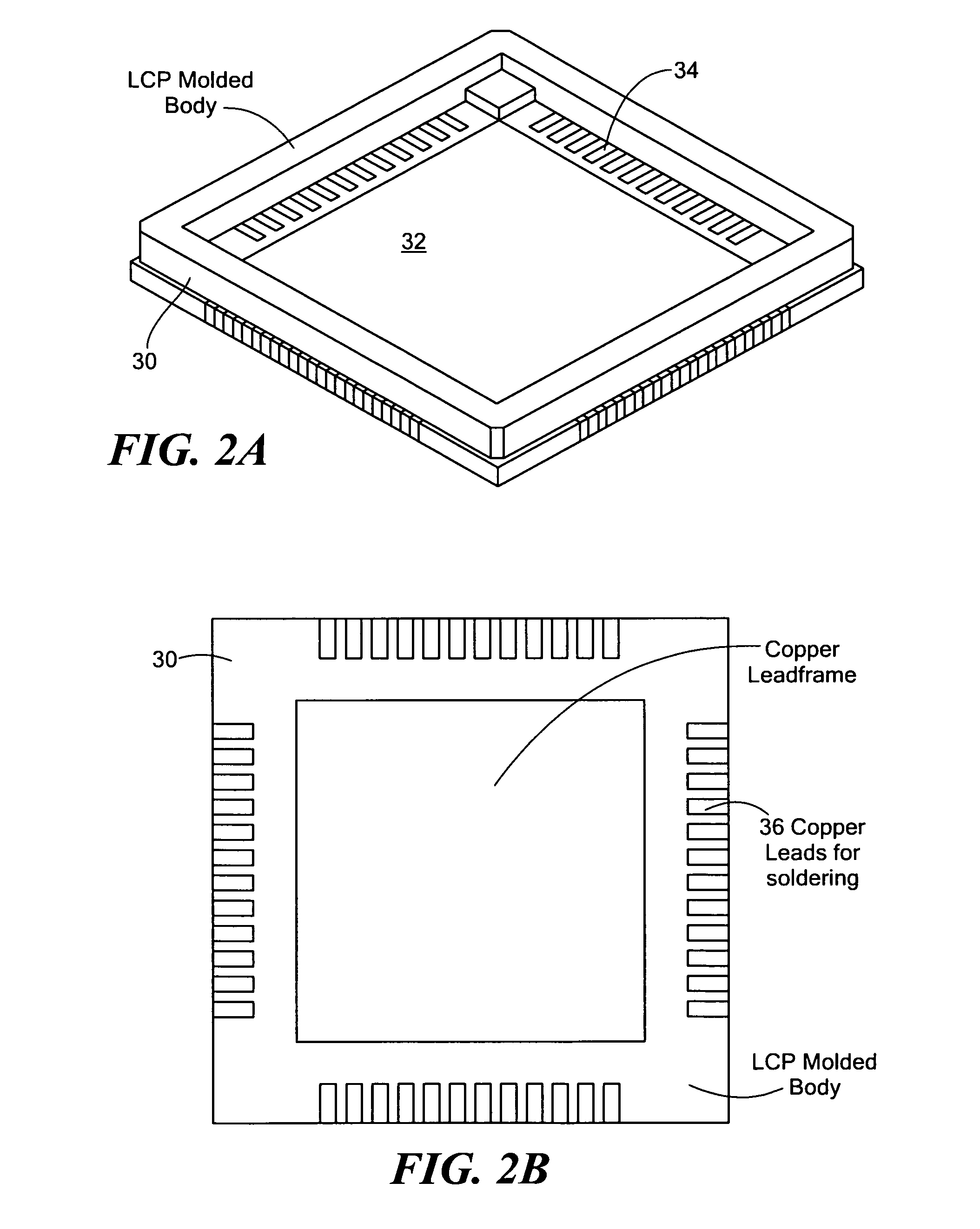

[0029]The image sensor package in accordance with the invention comprises a high temperature thermoplastic body or frame, preferably an LCP material, molded around a metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting temperature | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com