Cathode current collector, and preparation method and application of cathode current collector

A current collector and negative electrode technology, which is applied in the field of negative electrode current collectors, can solve the problems of reducing the service life of lithium-ion batteries, copper plating shedding, copper plating shedding, etc., and achieves the problems of copper plating shedding, strong tensile strength, and reduced shedding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

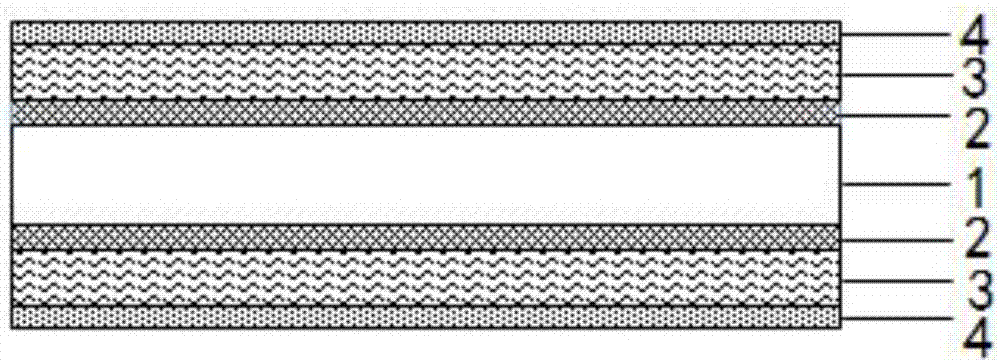

[0044] A preparation method of a negative electrode current collector, comprising the steps of:

[0045] S1. First, corona treatment is performed on the surface of the plastic film to be coated, and then the reel plastic film is placed in the vacuum chamber of the double-sided reciprocating magnetron sputtering coating machine, the vacuum chamber is sealed, and the vacuum is gradually evacuated until the vacuum degree reaches 3× 10 -3 -6×10 -3 Pa, double-sided back-and-forth high-efficiency coating on the plastic film by magnetron sputtering, the target material is nickel, the purity is ≥99.9%, adjust the unwinding speed and winding speed, and the sputtered nickel atoms form a layer on the moving film Nickel-plated layer, that is, the adhesion-enhancing layer;

[0046] S2. Put the nickel-plated film obtained in S1 into the vacuum chamber of the double-sided reciprocating evaporation coating machine, seal the vacuum chamber, and evacuate step by step until the vacuum degree r...

Embodiment 2

[0050] A preparation method of a negative electrode current collector, comprising the steps of:

[0051] S1. First, corona treatment is performed on the surface of the plastic film to be coated, and then the reel plastic film is placed in the vacuum chamber of the double-sided reciprocating magnetron sputtering coating machine, the vacuum chamber is sealed, and the vacuum is gradually evacuated until the vacuum degree reaches 3× 10 -3 -6×10 -3 Pa, double-sided back-and-forth high-efficiency coating on the plastic film by magnetron sputtering, the target material is nickel, the purity is ≥99.9%, adjust the unwinding speed and winding speed, and the sputtered nickel atoms form a layer on the moving film Nickel-plated layer, that is, the adhesion-enhancing layer;

[0052] S2. Put the nickel-plated film obtained in S1 into the vacuum chamber of the double-sided reciprocating evaporation coating machine, seal the vacuum chamber, and evacuate step by step until the vacuum degree r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com