Preparation method for copper/zinc coating on surface of glass fiber

A glass fiber and coating technology, which is applied in the field of composite glass fiber material preparation, can solve the problems of large equipment investment and complicated process, and achieve the effect of increasing specific surface area, low process cost, and suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

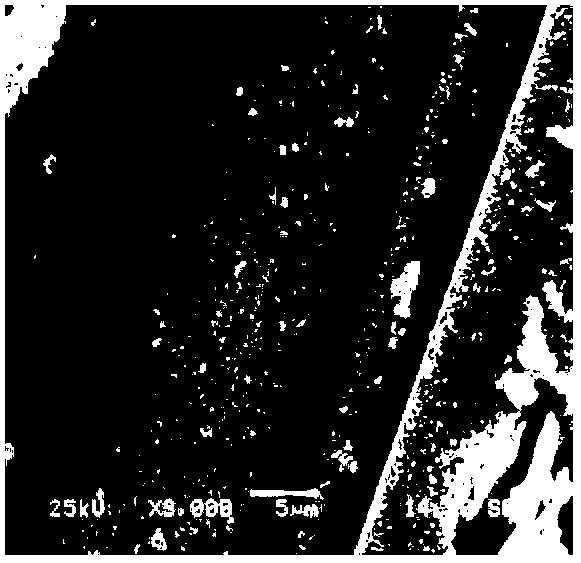

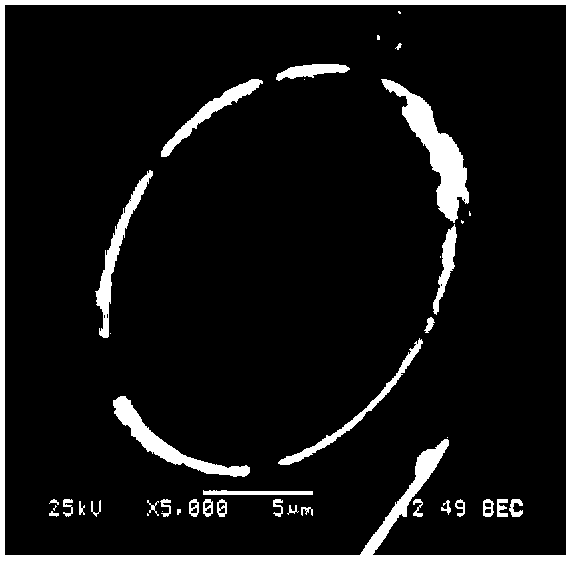

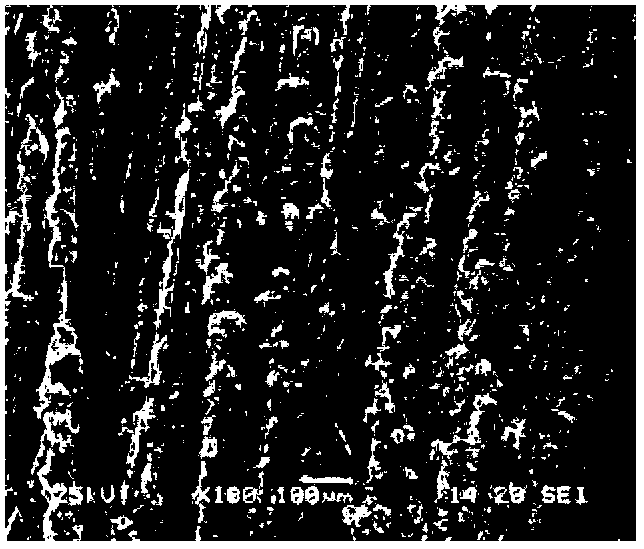

Image

Examples

Embodiment 1

[0045] A preparation method for a glass fiber surface copper / zinc coating, comprising the steps of:

[0046] The first step: glass fiber surface pretreatment

[0047] Carry out degreasing, roughening, sensitization, activation and reduction pretreatment on the surface of glass fiber;

[0048] The surface degreasing is to heat the glass fiber at 400°C for 48 hours, soak it in acetone solution for 48 hours, then place it in absolute ethanol for 5 minutes of ultrasonic vibration, and then wash it with distilled water;

[0049] The roughening is to put the degreased glass fiber into the roughening solution, wash it with distilled water after treating it in an ultrasonic water bath environment for 5 minutes, and dry it at 40°C for 10 minutes; the roughening solution is to add 30ml of hydrogen to 100ml of distilled water Prepared from hydrofluoric acid and 1g of ammonium fluoride;

[0050] The sensitization is to immerse the roughened glass fiber in the sensitization solution for ...

Embodiment 2

[0070] A preparation method for a glass fiber surface copper / zinc coating, comprising the steps of:

[0071] The first step: glass fiber surface pretreatment

[0072] Carry out degreasing, roughening, sensitization, activation and reduction pretreatment on the surface of glass fiber;

[0073] The surface degreasing is to heat the glass fibers at 500°C for 10 hours, soak them in acetone solution for 36 hours, then place them in absolute ethanol for 10 minutes of ultrasonic vibration, and then wash them with distilled water;

[0074] The roughening is to put the degreased glass fiber into the roughening solution, wash it with distilled water after treatment in an ultrasonic water bath environment for 10 minutes, and dry it at 50°C for 30 minutes; the roughening solution is to add 20ml of hydrogen to 100ml of distilled water Prepared from hydrofluoric acid and 5g ammonium fluoride;

[0075] The sensitization is to immerse the roughened glass fiber in the sensitization solution ...

Embodiment 3

[0095] A preparation method for a glass fiber surface copper / zinc coating, comprising the steps of:

[0096] The first step: glass fiber surface pretreatment

[0097] Carry out degreasing, roughening, sensitization, activation and reduction pretreatment on the surface of glass fiber;

[0098] The surface degreasing is to heat the glass fibers at 600°C for 20 hours, soak them in acetone solution for 48 hours, then place them in absolute ethanol for 15 minutes of ultrasonic vibration, and then wash them with distilled water;

[0099] The roughening is to put the degreased glass fiber into the roughening solution, wash it with distilled water after treating it in an ultrasonic water bath environment for 20 minutes, and dry it at 60°C for 50 minutes; the roughening solution is to add 30ml of hydrogen to 100ml of distilled water Prepared from hydrofluoric acid and 6g of ammonium fluoride;

[0100] The sensitization is to immerse the roughened glass fiber in the sensitization solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com