Preparation method of high-nickel positive electrode material for lithium ion battery

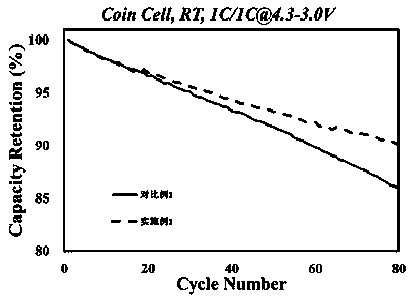

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as damage, poor cycle performance, and attenuation of material cycle performance, and achieve inhibition of precipitation, good crystallinity, and improved stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Configure a salt solution with a concentration of 2mol / L, in which the molar ratio of nickel sulfate, cobalt sulfate and manganese sulfate is 88:9:3, and configure the alkali into an alkali solution with a concentration of 3mol / L; configure the complexing agent into 1mol / aqueous ammonia solution;

[0046] (2) Add the salt solution, alkali solution and complexing agent solution together into the reaction kettle for reaction, keep the stirring speed constant during the process, pass an inert atmosphere of argon for protection, and control the reaction pH to 11.8 and the reaction temperature to 45 ℃, the concentration of the complexing agent ammonia water in the reaction system is controlled to 3g / L, when the reaction is completed, stop the liquid feeding, keep the temperature of the reaction liquid and the stirring speed constant, and continue to stir for 120min to obtain the hydroxide precursor slurry;

[0047] (3) After the hydroxide precursor slurry in step (2) is ...

Embodiment 2

[0052] (1) Prepare a salt solution with a concentration of 1.5mol / L, in which the molar ratio of nickel sulfate, cobalt sulfate and manganese sulfate is 83:10:7, and configure the alkali into an alkali solution with a concentration of 2mol / L; Configured as 3mol / ammonia solution;

[0053] (2) Put the salt solution, alkali solution and complexing agent solution together into the reaction kettle for reaction, keep the stirring speed constant during the process, pass an inert atmosphere of argon for protection, and control the reaction pH to 12.3 and the reaction temperature to 55 °C, the concentration of the complexing agent ammonia water in the reaction system is controlled to 2g / L. When the reaction is completed, stop the liquid feeding, keep the temperature of the reaction liquid and the stirring speed constant, and continue stirring for 120min to obtain the hydroxide precursor slurry.

[0054] (3) After the hydroxide precursor slurry in step (2) is subjected to solid-liquid ...

Embodiment 3

[0059] (1) Configure a salt solution with a concentration of 2.5mol / L, in which the molar ratio of nickel sulfate and cobalt sulfate is 88:9, prepare the alkali solution and aluminum nitrate solution to form a 0.2mol / L aluminum solution, and configure the alkali to a concentration of It is a 3mol / L alkali solution; the complexing agent is configured into a 1mol / L ammonia solution;

[0060] (2) Put the salt solution, aluminum solution, alkali solution, and complexing agent solution together into the reaction kettle for reaction, keep the stirring speed constant during the process, pass an inert atmosphere of argon for protection, and control the reaction pH to 12.6 at the same time. The temperature is 50°C, and the concentration of the complexing agent ammonia water in the reaction system is controlled at 3g / L. When the reaction is completed, stop feeding the liquid, keep the temperature of the reaction liquid and the stirring speed constant, and continue stirring for 120 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com