Deoxidizer carrier as well as sulfur-resisting deoxidizer based on carrier and preparation method of carrier

A deoxidizer and sulfur-resistant technology, applied in the field of coal gasification, can solve the problems of less than one year life, high price, poor mechanical strength, etc., and achieve the effect of good sulfur-resistant deoxidation performance, low price, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

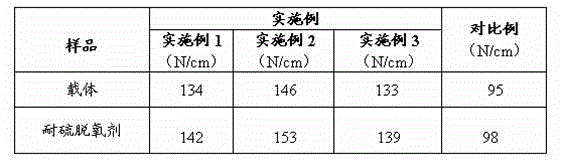

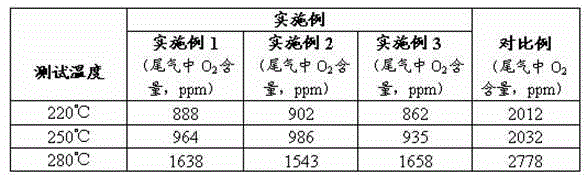

Examples

Embodiment 1

[0039] The sulfur-resistant deoxidizer carrier in this example is prepared from the following raw materials:

[0040] Modified bauxite powder, 5 parts by weight;

[0041] Aluminum oxide powder, 80 parts by weight;

[0042] Titanium dioxide powder, 1 part by weight;

[0043] Peptizer, 5 parts by weight;

[0044] Pore-forming agent, 5 parts by weight;

[0045] Adhesive, 2 parts by weight;

[0046] Extrusion aid, 2 parts by weight.

[0047] The particle diameters of the modified bauxite powder, alumina powder and titanium dioxide powder are all 100 mesh. The peptizing agent is malonic acid; the pore-forming agent is citric acid; the extrusion aid is squash powder; and the binder is titanate.

[0048] The preparation method of the sulfur-resistant deoxidizer carrier described in this embodiment is:

[0049] (1) Fully knead the modified bauxite powder, alumina powder and titanium dioxide powder in the above parts by weight;

[0050] (2) Then add the peptizer, pore ...

Embodiment 2

[0056] The sulfur-resistant deoxidizer carrier in this example is prepared from the following raw materials:

[0057] Modified bauxite powder, 30 parts by weight;

[0058] Aluminum oxide powder, 50 parts by weight;

[0059] Titanium dioxide powder, 8 parts by weight;

[0060] Peptizer, 3 parts by weight;

[0061] Pore-forming agent, 3 parts by weight;

[0062] Adhesive, 4 parts by weight;

[0063] Extrusion aid, 2 parts by weight.

[0064] The particle diameters of the modified bauxite powder, alumina powder and titanium dioxide powder are all 120 mesh. The peptizing agent is nitric acid; the pore-forming agent is a mixture of oxalic acid and citric acid with a mass ratio of 4:1; the extrusion aid is squash powder, and the binder is cement.

[0065] The preparation method of the sulfur-resistant deoxidizer carrier described in this embodiment includes:

[0066] (1) Fully knead the bauxite powder, alumina powder and titanium dioxide powder in the above parts by we...

Embodiment 3

[0073] The oxygen-resistant deoxidizer carrier in this example is prepared from the following raw materials:

[0074] Modified bauxite powder, 10 parts by weight;

[0075] Aluminum oxide powder, 56 parts by weight;

[0076] Titanium dioxide powder, 10 parts by weight;

[0077] Peptizer, 8 parts by weight;

[0078] Pore-forming agent, 8 parts by weight;

[0079] Adhesive, 4 parts by weight;

[0080] Extrusion aid, 2 parts by weight.

[0081] The particle diameters of the modified bauxite powder, alumina powder and titanium dioxide powder are all 150 mesh. The peptizer is a mixture of malonic acid and nitric acid with a mass ratio of 1:9; the pore-forming agent is oxalic acid; the extrusion aid is squash powder; and the binder is titanate.

[0082] The preparation method of the oxygen-resistant deoxidizer carrier described in this embodiment includes:

[0083] (1) Fully knead the bauxite powder, alumina powder and titanium dioxide powder in the above parts by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com