Powder metallurgy production technological method

A production process and powder metallurgy technology, applied in the field of powder metallurgy production process, can solve the problems of easily causing cracks, slow cooling efficiency, affecting the quality of parts, etc., and achieve the effects of improving product quality, improving quality, and eliminating stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

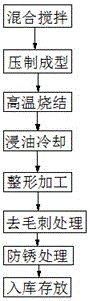

[0017] A powder metallurgy production process, the powder metallurgy production process comprises the following steps:

[0018] The first step: mixing and stirring, mixing the raw metal powder according to the ratio, filtering the mixed metal powder with a filter, and then adding the filtered metal powder to the stirring device to stir evenly;

[0019] The second step: press molding, pour the evenly stirred metal powder directly into the compact mold, and press the press to make the shape of the blank of the part, and the pressure of the press is 160Mpa;

[0020] The third step: high-temperature sintering, the part blank is sent to the heating furnace through the mesh belt conveyor for sintering to form a dense semi-finished product, the sintering time is 2 hours, and the heating temperature is 1200°C.

[0021] The fourth step: oil immersion cooling, the sintered semi-finished product is immersed in oil for cooling, the cooled oil temperature is 18°C, and then the cooled semi-...

Embodiment 2

[0027] A powder metallurgy production process, the powder metallurgy production process comprises the following steps:

[0028] The first step: mixing and stirring, mixing the raw metal powder according to the ratio, filtering the mixed metal powder with a filter, and then adding the filtered metal powder to the stirring device to stir evenly;

[0029] The second step: press molding, pour the evenly stirred metal powder directly into the compact mold, and press the press to make the shape of the blank of the part. The pressure of the press is 220Mpa;

[0030] The third step: high-temperature sintering, the part blank is sent to the heating furnace through the mesh belt conveyor for sintering to form a dense semi-finished product, the sintering time is 2.5 hours, and the heating temperature is 1250°C.

[0031] The fourth step: oil immersion cooling, the sintered semi-finished product is immersed in oil for cooling, the cooled oil temperature is 22°C, and then the cooled semi-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com