Anchoring blasting hole-sealing material and preparation method thereof

A sealing material and anchoring technology, which is applied in the field of anchoring and blasting sealing materials and its preparation, can solve the problems of long setting and hardening time, low impact resistance performance, and high production cost, and achieve enhanced curing performance, improved corrosion resistance, and improved compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

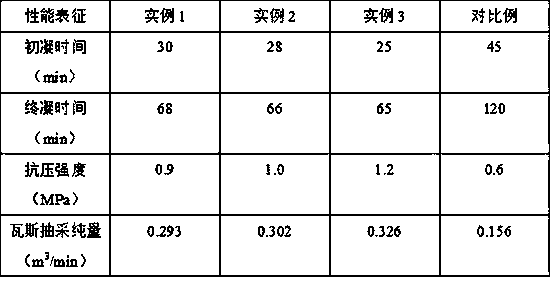

Examples

example 1

[0023] Take 20g of sodium metaaluminate, 10g of calcium chloride, 0.3g of triethanolamine, 5g of naphthalenesulfonic acid-based water reducer, add 550mL of deionized water, stir at 300r / min for 5min, then add 3g of phosphoric acid, 5g of polyethylene oxide, 8g Hard foam silicone oil SD-502, 80g bentonite, continue to stir for 10min, then add 100g lithium magnesium silicate, 12g polyvinyl acetate emulsion, 10g silane coupling agent A-171, stir at 200r / min for 10min to obtain cement additives, mix cement The additive is evenly sprayed into 1.0kg of ordinary Portland cement 32.5R, put into the mixing tank and stirred for 3 minutes, and the material is discharged to obtain the anchoring and blasting sealing material.

example 2

[0025] Take 23g of sodium metaaluminate, 13g of calcium chloride, 0.4g of triethanolamine, 7g of polycarboxylate water reducer, add 575mL of deionized water, stir at 350r / min for 7min, then add 4g of silicate, 6.5g of organic silicon Oxyalkylene condensation polymer, 10g Pingpingjia, 90g bentonite, continue to stir for 13min, then add 125g magnesium silicate lithium, 16g styrene-butadiene emulsion, 15g silane coupling agent 1110, stir at 250r / min for 13min, to obtain cement additive, cement additive The agent is evenly sprayed into 1.1kg of ordinary Portland cement 32.5R, put into the mixing tank and stirred for 4 minutes, and the material is discharged to obtain the anchoring blasting sealing material.

example 3

[0027] Take 25g of sodium metaaluminate, 15g of calcium chloride, 0.5g of triethanolamine, and 8g of melamine-based high-efficiency water reducer, add it to 600mL of deionized water, stir at 400r / min for 10min, then add 5g of sodium oleate, 8g of organosiloxane Condensation polymer, 12g polyoxyethylene stearate, 100g bentonite, continue to stir for 15min, add 150g magnesium silicate lithium, 20g acrylic acid emulsion, 20g silane coupling agent KH-560, stir 15min with 300r / min, get cement Auxiliary, spray the cement additive evenly into 1.2kg of ordinary Portland cement 32.5R, put it into the mixing tank and stir for 5 minutes, and discharge the material to obtain the anchoring blasting sealing material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com