High cement paste solidifying agent

A mud curing agent and high water technology, applied in chemical instruments and methods, wellbore/well parts, applications, etc., can solve the problems of low curing strength, impossibility, slow setting and hardening, etc., achieve good curing effect and simple process , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

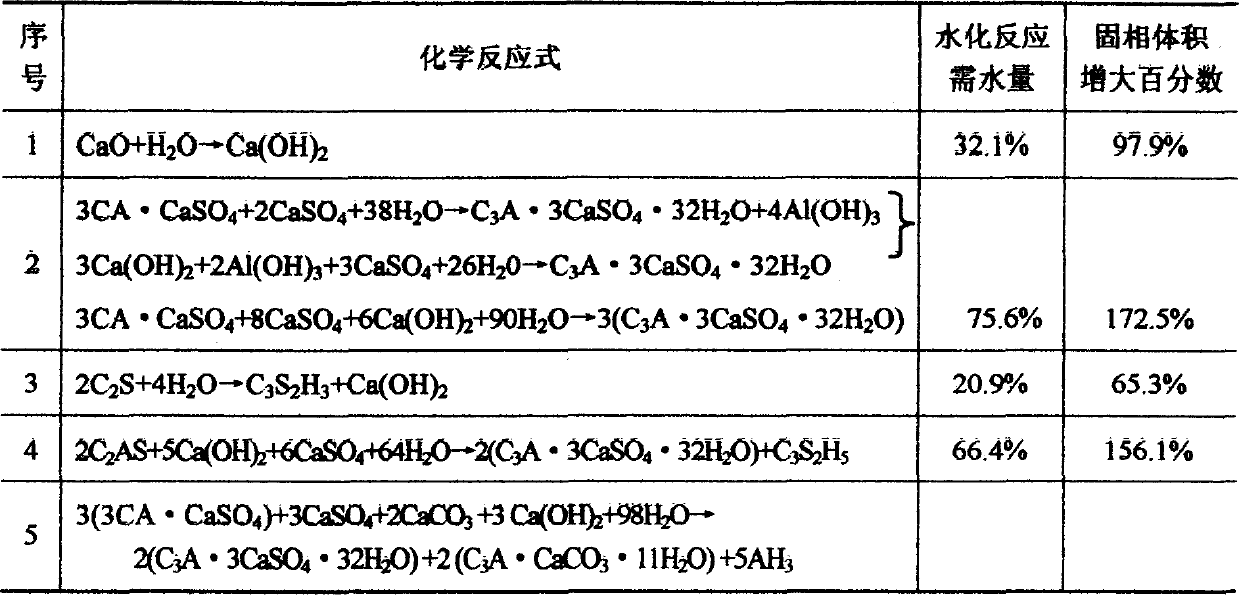

[0045] Figure 1 is the hydration reaction of high cement slurry curing agent. Figure 2 lists the chemical composition of the raw materials used in the implementation.

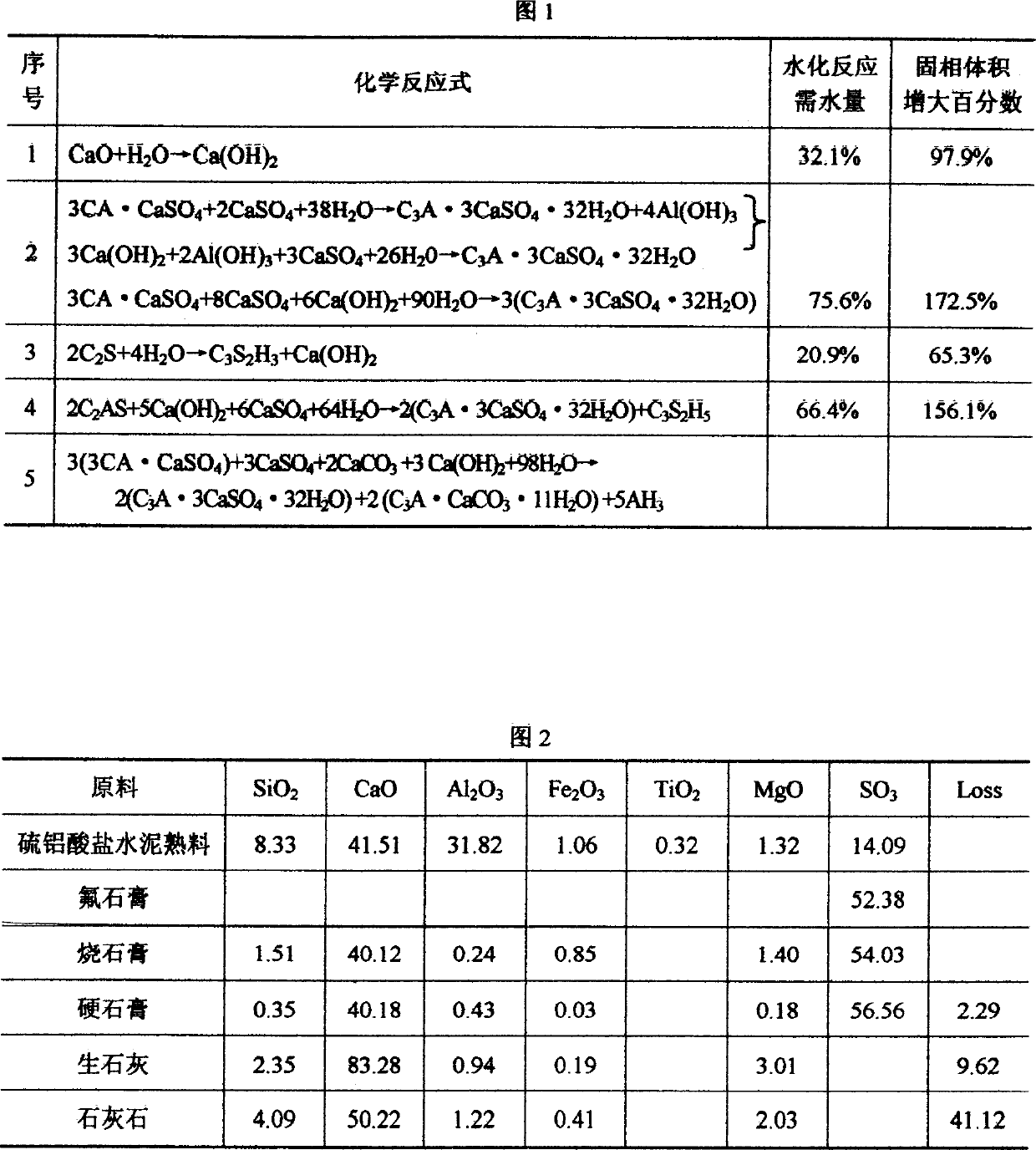

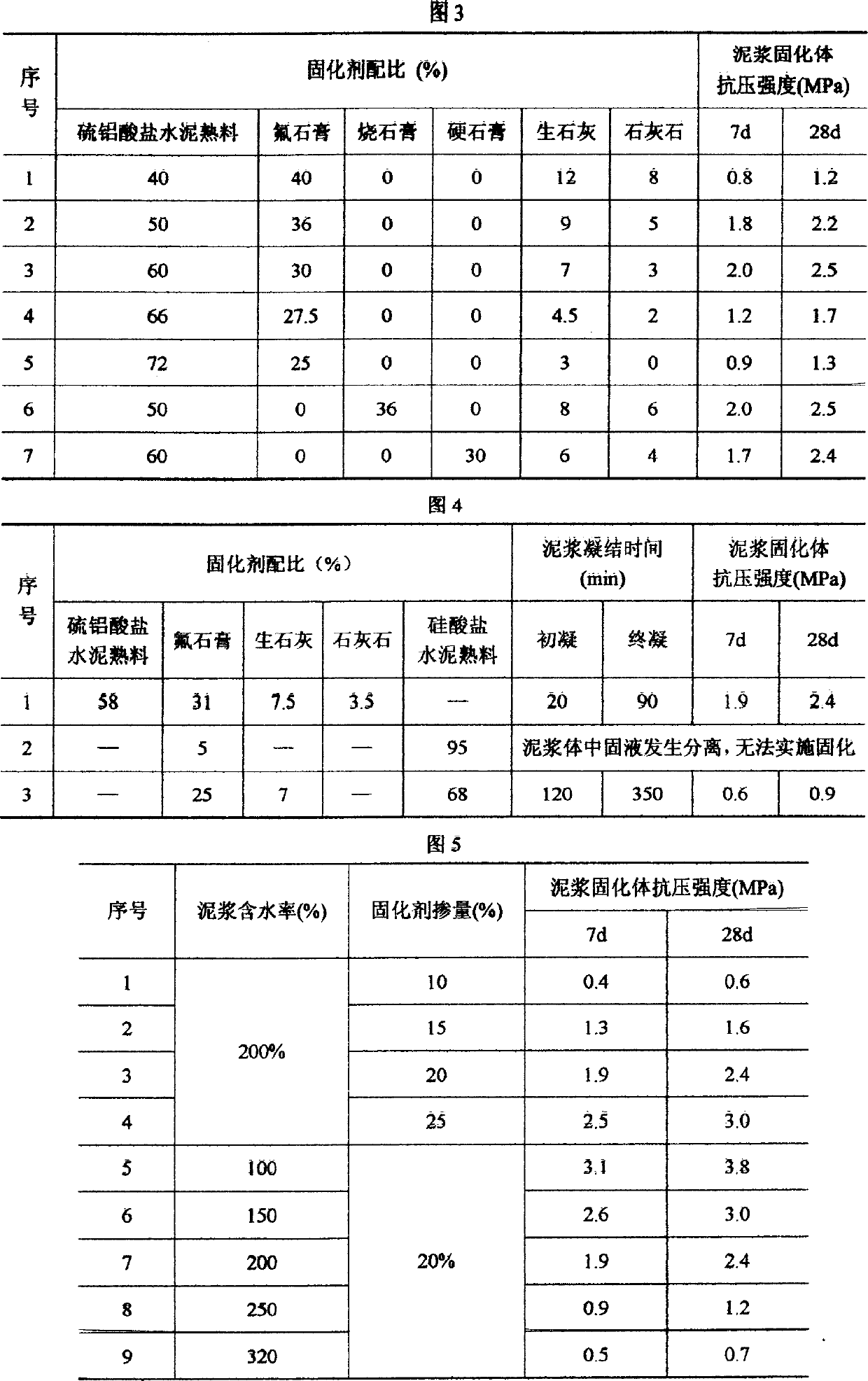

[0046] Figure 3 is an example of the mass ratio of high cement slurry curing agent. Figure 3 lists the ratio of high cement slurry curing agent and its curing performance. Among them: the curing agent used is made by mixing and grinding, and the specific surface area is 370m 2 / kg: The mud to be solidified is waste mud from an oilfield, with a water content of 200%; the amount of curing agent is 20% (based on the mud quality), and after mixing with the mud evenly, inject 70.7×70.7×70.7mm 3 Cubic mold test, placed in a curing room with a temperature of 20±2°C and a relative humidity above 90% for curing, demoulding after 2 days, continuing curing after demoulding, and measuring the unconfined compressive strength of the solidified mud body at the specified age.

[0047] Figure 4 lists the comparison of the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com