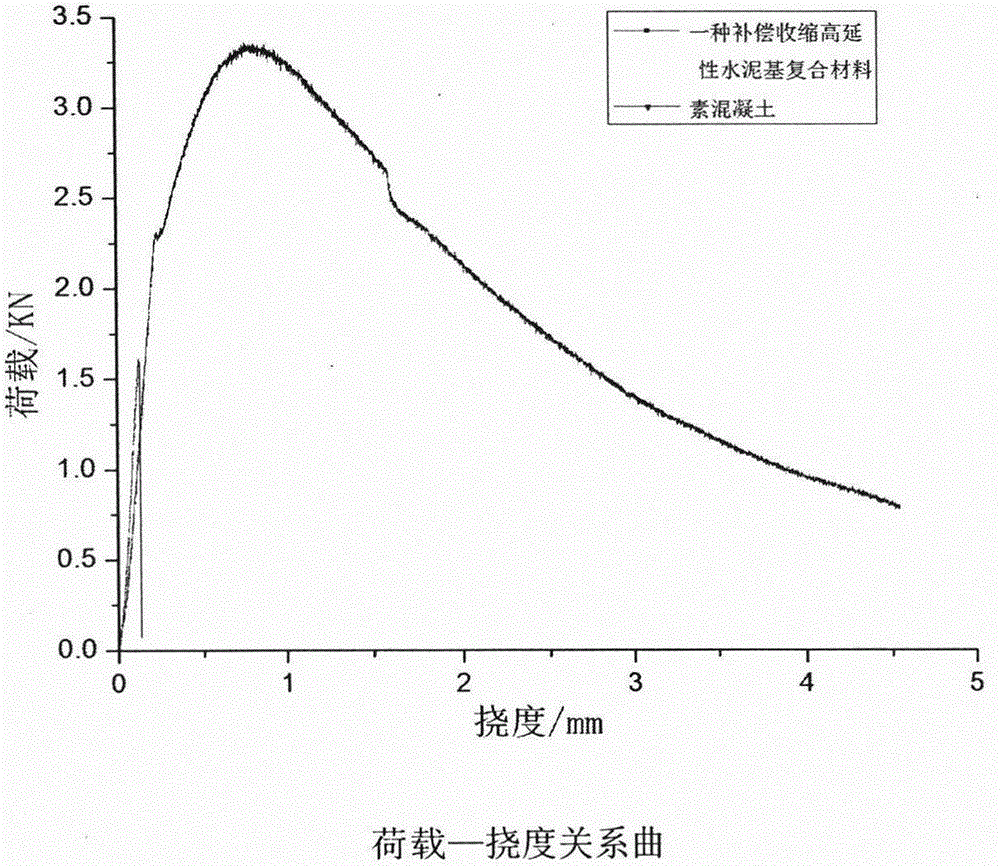

Shrinkage-compensating and high-ductility cement-based composite material

A composite material and shrinkage compensation technology, applied in the field of concrete materials, can solve the problems of large dry shrinkage in the hydration hardening process of ECC, restrictions on popularization and application, and limitations in adaptability, etc., to improve various performance indicators, low shrinkage characteristics, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: The volume ratio of polyester fibers is 0.9%, and other components except fibers are recorded as 60 parts of cement by weight ratio, 10 parts of silica fume, 40 parts of fly ash, 7 parts of expansion agent, and water reducer 0.4 parts, 50 parts of sand, 35 parts of water.

Embodiment 2

[0025] Example 2: The volume ratio of the steel fiber is 1.8%, and other components except the fiber are recorded as 58 parts of cement, 5 parts of silica fume, 50 parts of fly ash, 8 parts of expansion agent, and 0.3 part of water reducer by weight ratio , 45 parts of sand, 33 parts of water.

Embodiment 3

[0026] Embodiment 3: the volume ratio of polyester fiber is 1.2%, other components except fiber are recorded as 58 parts of cement, 50 parts of fly ash, 8 parts of expansion agent, 0.3 part of water reducer, 48 parts of sand by weight ratio , 30 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com