Waterproof construction method of anti-floating anchor

A technology of anti-floating anchor rods and construction methods, applied in infrastructure engineering, protection devices, buildings, etc., can solve the hidden danger of water leakage at the interface between the anchor rod and SBS waterproof membrane, the hidden danger of water leakage at the interface between the anchor rod and waterproof membrane, etc. problems, to achieve the effect of reducing the risk of water leakage, high tensile strength, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

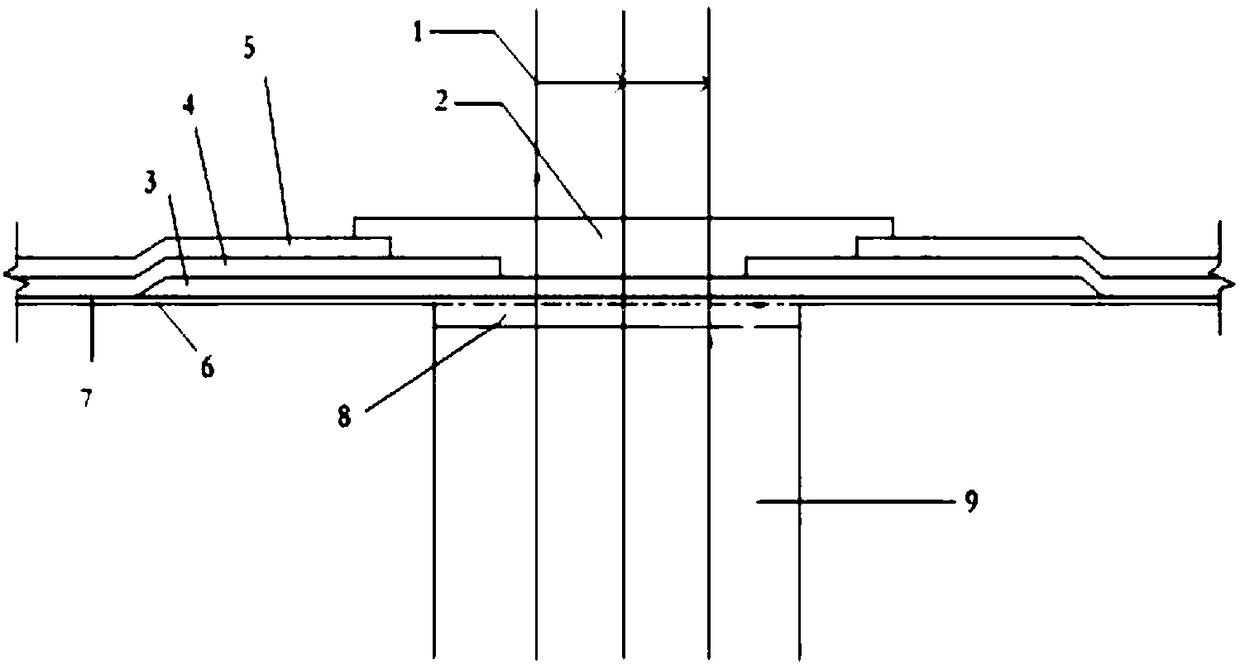

[0033] (1) Cushion 6 is poured at the bottom of the foundation pit, and on the cushion 6, holes are drilled at intervals successively with a bolt drill. After the rig drills into the design depth of 12m, a pressure grouting is started immediately, and the drill rod is lifted while Inject cement mortar until the cement mortar overflows from the bore hole 9;

[0034] (2) After the initial setting of the cement mortar of the primary pressure grouting and before the final setting, the secondary grouting pipe is lowered together with the anti-floating anchor rod 1 into the borehole of the primary pressure grouting. If it is difficult to lower the local position, use The vibrating hammer is assisted in lowering to control the exposed length of the anchor bar to 600mm;

[0035] (3) Use the secondary grouting pipe for secondary grouting;

[0036] (4) After the mortar slurry strength of the secondary grouting reaches 90% of the design strength 30MPa, carry out the pull-out bearing cap...

Embodiment 2

[0045] (1) Cushion 6 is poured at the bottom of the foundation pit, and on the cushion 6, holes are drilled at intervals successively with a bolt drill. After the rig drills into the design depth of 16m, a pressure grouting is started immediately, and the drill pipe is lifted while Inject cement mortar until the cement mortar overflows from the bore hole 9;

[0046] (2) After the initial setting of the cement mortar of the primary pressure grouting and before the final setting, the secondary grouting pipe is lowered together with the anti-floating anchor rod 1 into the borehole of the primary pressure grouting. If it is difficult to lower the local position, use The vibrating hammer is assisted in lowering to control the exposed length of the anchor bar to 800mm;

[0047] (3) Use the secondary grouting pipe for secondary grouting;

[0048] (4) After the mortar slurry strength of the secondary grouting reaches 90% of the design strength 30MPa, carry out the pull-out bearing ca...

Embodiment 3

[0057] (1) Cushion 6 is poured at the bottom of the foundation pit, and on the cushion 6, holes are drilled at intervals successively with a bolt drill. After the rig drills into the design depth of 17m, a pressure grouting is started immediately, and the drill rod is lifted while Inject cement mortar until the cement mortar overflows from the bore hole 9;

[0058] (2) After the initial setting of the cement mortar of the primary pressure grouting and before the final setting, the secondary grouting pipe is lowered together with the anti-floating anchor rod 1 into the borehole of the primary pressure grouting. If it is difficult to lower the local position, use The vibrating hammer is assisted in lowering to control the exposed length of the anchor bar to 700 mm;

[0059] (3) Use the secondary grouting pipe for secondary grouting;

[0060] (4) After the mortar slurry strength of the secondary grouting reaches 90% of the design strength 30MPa, carry out the pull-out bearing ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com