Low-temperature-rise anti-corrosion maritime mass concrete and preparation method thereof

A technology for marine engineering and concrete, applied in the field of building materials, can solve the problems of rising adiabatic temperature, reduced corrosion resistance, and high durability requirements, and achieve the effects of reducing hydration adiabatic temperature rise, reducing temperature cracks, and reducing cement consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation of the hydration accelerator comprises the following steps:

[0037] 1) Carry out esterification reaction with methacrylic acid and polyethylene glycol monomethyl ether in a mass ratio of 2:1 to synthesize polyethylene glycol monomethyl ether methacrylate monomer with super-dispersion water-reducing function; Allyl alcohol, ammonia water and propylene oxide are weighed in a molar ratio of 1:0.3:0.8, using sodium methallylate or potassium methallylate as a catalyst, under the conditions of a pressure of 0.2MPa and a temperature of 100°C React for 5 hours to obtain methallyl alcohol polyoxypropylene ether, wherein the mass of the catalyst is 0.25% of the mass of methallyl alcohol;

[0038] 2) Weigh each component according to the following proportions: polyethylene glycol monomethyl ether methacrylate monomer 65%, methallyl alcohol polyoxypropylene ether 8%, sodium methacryl sulfonate 1%, three Isopropanolamine 22%, acrylamide 4%, weighed polyethylene gly...

Embodiment 1~3

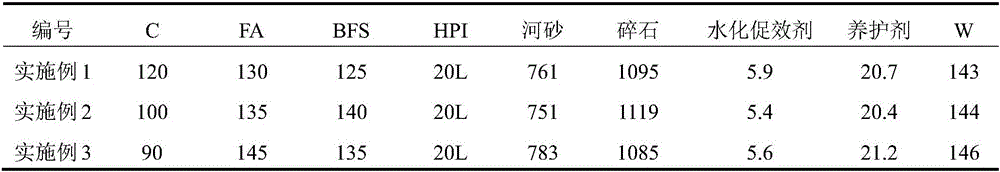

[0047] Weigh the raw materials according to the mix ratio in Table 1-1 to prepare C30 concrete, which is used to prepare large-volume concrete for marine engineering. The performance test results are shown in Table 1-2.

[0048] Table 1-1 C30 Marine Mass Concrete Mix Ratio Unit: kg / m 3

[0049]

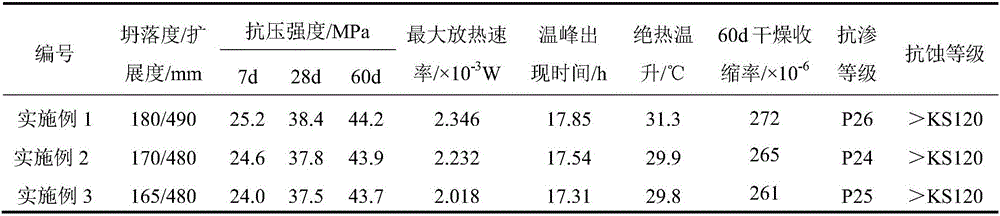

[0050] Table 1-2 Performance Test Results of C30 Marine Mass Concrete

[0051]

Embodiment 4~6

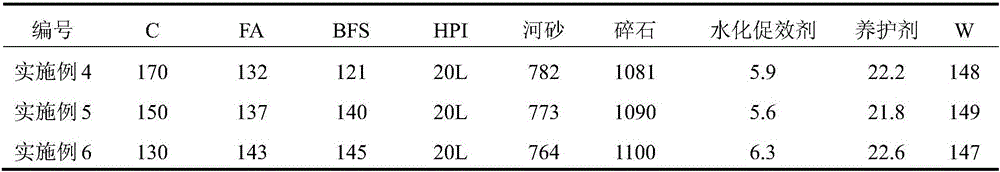

[0053] Weigh the raw materials according to the mix ratio in Table 2-1 to prepare C40 concrete. The performance test results are shown in Table 2-2.

[0054] Table 2-1 Mix ratio of C40 marine mass concrete Unit: kg / m 3

[0055]

[0056] Table 2-2 Performance Test Results of C40 Marine Mass Concrete

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com