Anti-cracking shrinkage-reducing concrete admixture and preparation method thereof

A concrete admixture and shrinkage technology, which is applied in the field of building materials, can solve the problems of cement paste performance decline, GO difficult to disperse uniformly, etc., and achieve the effect of improving the bubble structure properties, improving work performance, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

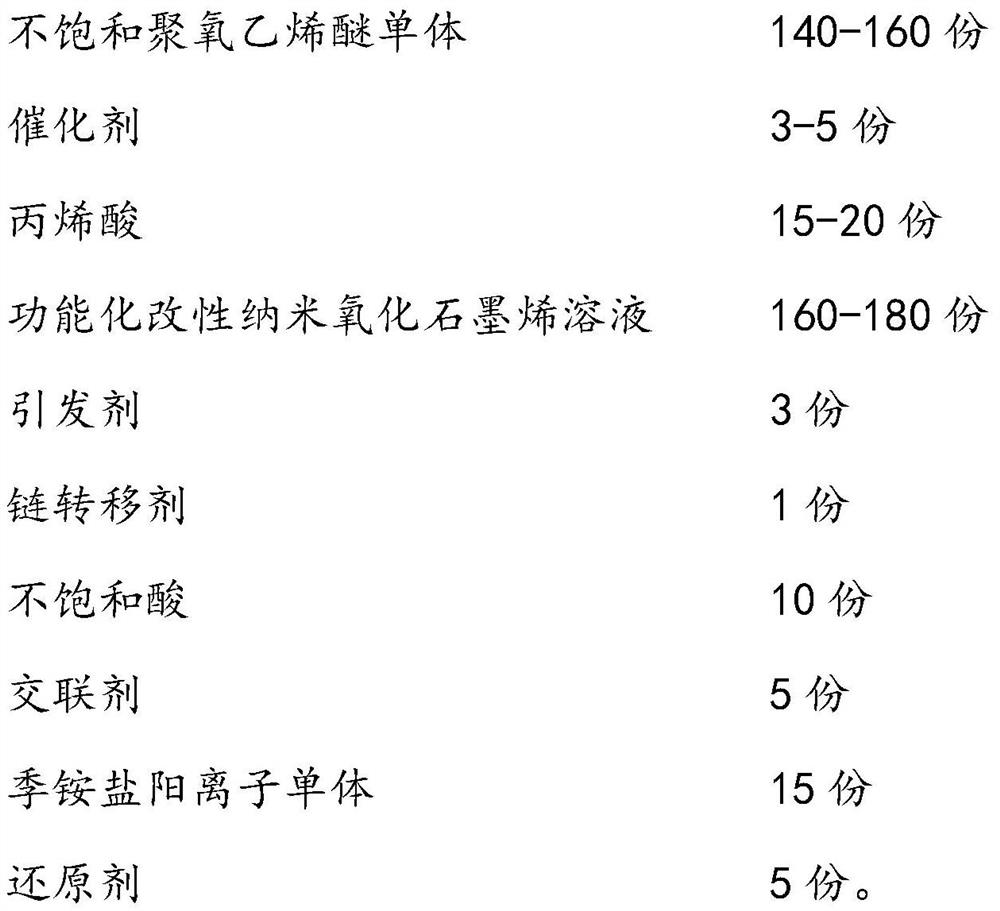

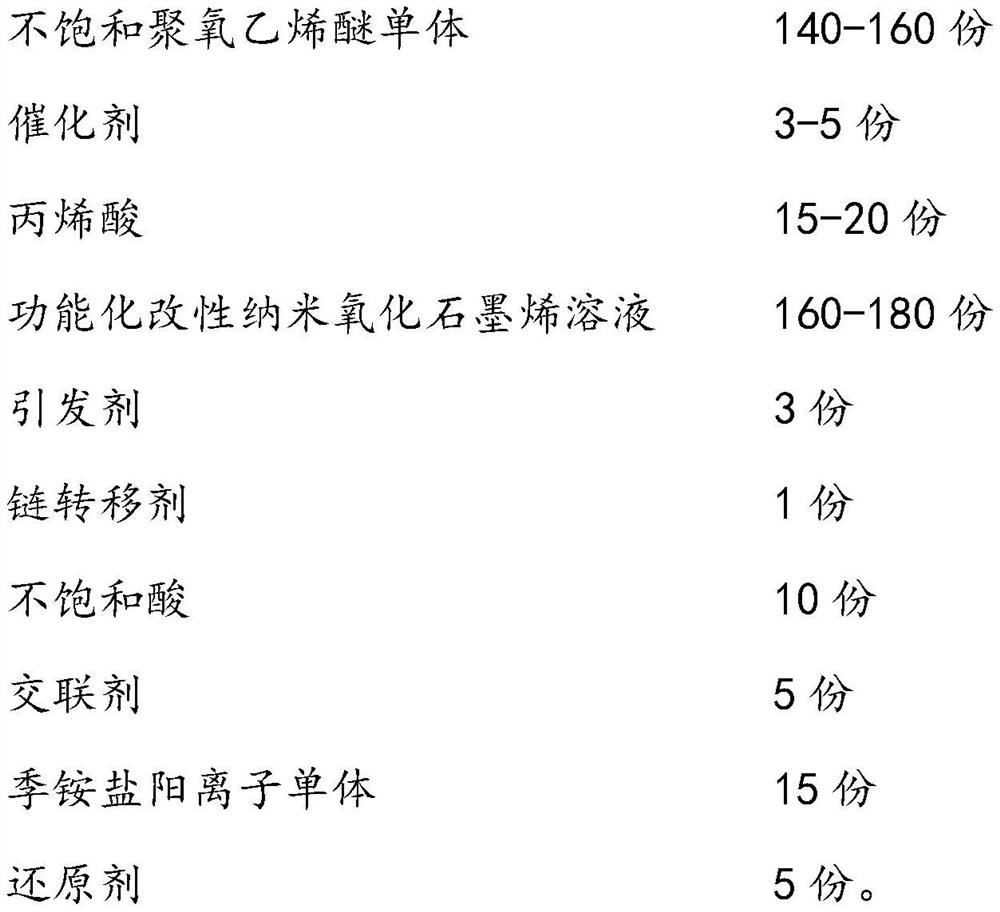

Method used

Image

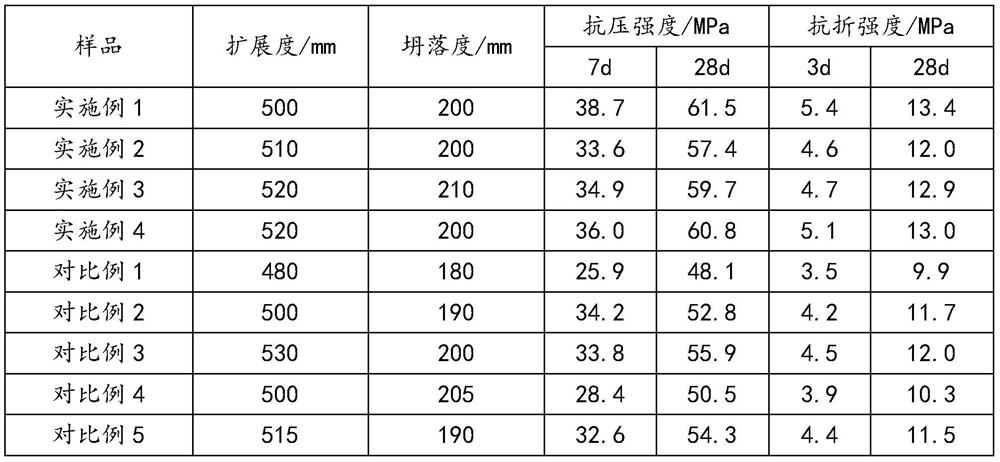

Examples

Embodiment 1

[0043] Step 1, adding 150 parts by weight of isopentenyl polyoxyethylene ether with a molecular weight of 3000, 3 parts by weight of N,N-diethylaniline and 18 parts by weight of acrylic acid to 160 parts by weight of a pre-prepared functional modified After ultrasonic treatment for 15 minutes, add it into the reaction device, heat to 80°C, and keep stirring;

[0044] Wherein, the preparation method of functionalized modified nano-graphene oxide solution is:

[0045]Step a, add 60 parts by weight of concentrated sulfuric acid, 1 part by weight of graphite powder, and 3 parts by weight of sodium nitrate in a four-necked flask, and ultrasonicate for 30 minutes. During the process, control the temperature of the solution below 5°C, and then add 5 parts by weight of Potassium permanganate was continuously stirred at a speed of 300r / min for 3h, and the temperature was controlled below 10°C during stirring. Then, the reaction device was transferred to a water bath condition of 40° C...

Embodiment 2

[0053] Step 1, adding 150 parts by weight of isopentenyl polyoxyethylene ether with a molecular weight of 3000, 3 parts by weight of N,N-diethylaniline and 18 parts by weight of acrylic acid to 160 parts by weight of a pre-prepared functional modified After ultrasonic treatment for 15 minutes, add it into the reaction device, heat to 80°C, and keep stirring;

[0054] Wherein, the preparation method of functionalized modified nano-graphene oxide solution is:

[0055] Step a, add 60 parts by weight of concentrated sulfuric acid, 1 part by weight of graphite powder, and 3 parts by weight of sodium nitrate in a four-necked flask, and ultrasonicate for 30 minutes. During the process, control the temperature of the solution below 5°C, and then add 5 parts by weight of Potassium permanganate was continuously stirred at a speed of 300r / min for 3h, and the temperature was controlled below 10°C during stirring. Then, the reaction device was transferred to a water bath condition of 40° ...

Embodiment 3

[0063] Step 1, adding 150 parts by weight of isopentenyl polyoxyethylene ether with a molecular weight of 3000, 3 parts by weight of N,N-diethylaniline and 18 parts by weight of acrylic acid to 160 parts by weight of a pre-prepared functional modified After ultrasonic treatment for 15 minutes, add it into the reaction device, heat to 80°C, and keep stirring;

[0064] Wherein, the preparation method of functionalized modified nano-graphene oxide solution is:

[0065] Step a, add 60 parts by weight of concentrated sulfuric acid, 1 part by weight of graphite powder, and 3 parts by weight of sodium nitrate in a four-necked flask, and ultrasonicate for 30 minutes. During the process, control the temperature of the solution below 5°C, and then add 5 parts by weight of Potassium permanganate was continuously stirred at a speed of 300r / min for 3h, and the temperature was controlled below 10°C during stirring. Then, the reaction device was transferred to a water bath condition of 40° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com