Liquid vaporizer adopting cast aluminium heating body

A heating body and vaporizer technology, applied in lighting and heating equipment, steam boilers, steam generation and other directions, can solve the problems of high surface temperature of heating rods, inoperable vaporizers, high power of electric heating rods, etc. Excellent electrical performance and anti-oxidative corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

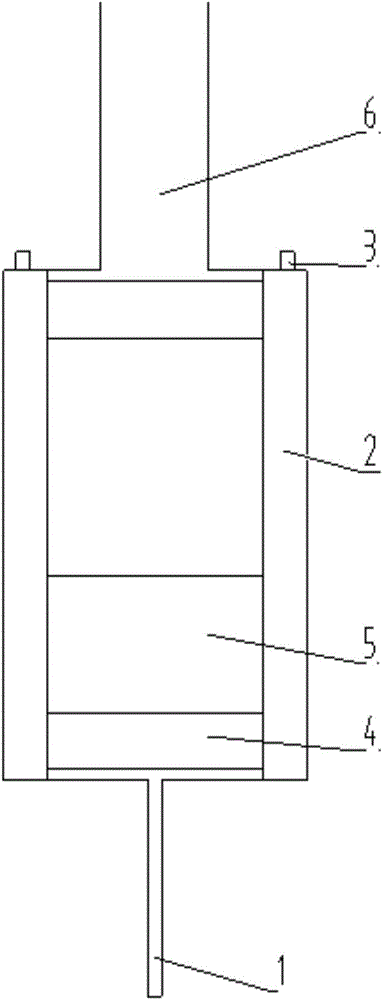

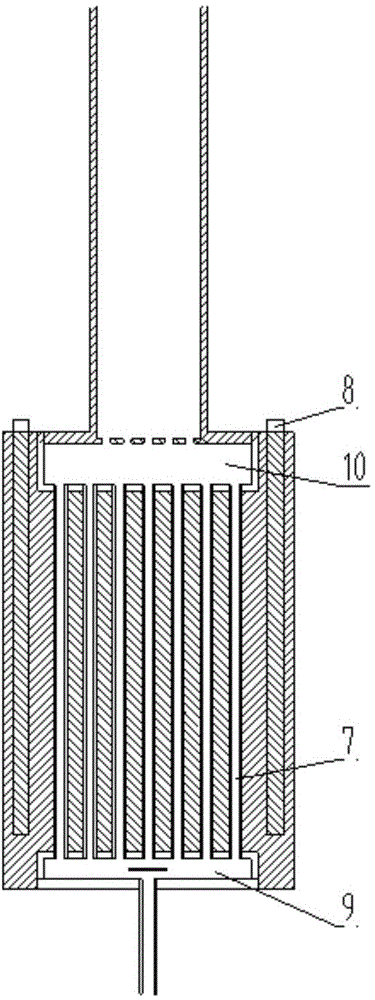

[0018] see figure 1 and figure 2 , the carburetor adopting the cast aluminum heating body of the present invention includes a liquid inlet 1, a cast aluminum heating body 2, an electric heating rod 3, an air outlet 6, and also includes a liquid storage chamber, and the liquid storage chamber consists of figure 2 The 7 straight pipes 7 are formed, and the cast aluminum heating body 2 is formed by casting molten aluminum on the surface of the electric heating rod 8 and the liquid storage chamber. The cast aluminum heating body 2 is made by casting.

[0019] The electric heating rod 3 is a U-shaped heating rod arranged outside the liquid phase pipes of the seven straight pipes. The liquid inlet of the liquid storage chamber is at the bottom of the cast aluminum heating body, the gas outlet of the vaporizer is at the top of the cast aluminum heating body, and the electric terminal of the electric heating rod 3 protrudes from the top of the cast aluminum heating body. see fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com